High-voltage power capacitor porcelain bottle transfer device

A transfer device and high-voltage power technology, applied in the field of electric power engineering, can solve the problems of poor use comfort, fixed storage capacity, inability to adjust, etc., and achieve the effect of convenient installation and disassembly, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

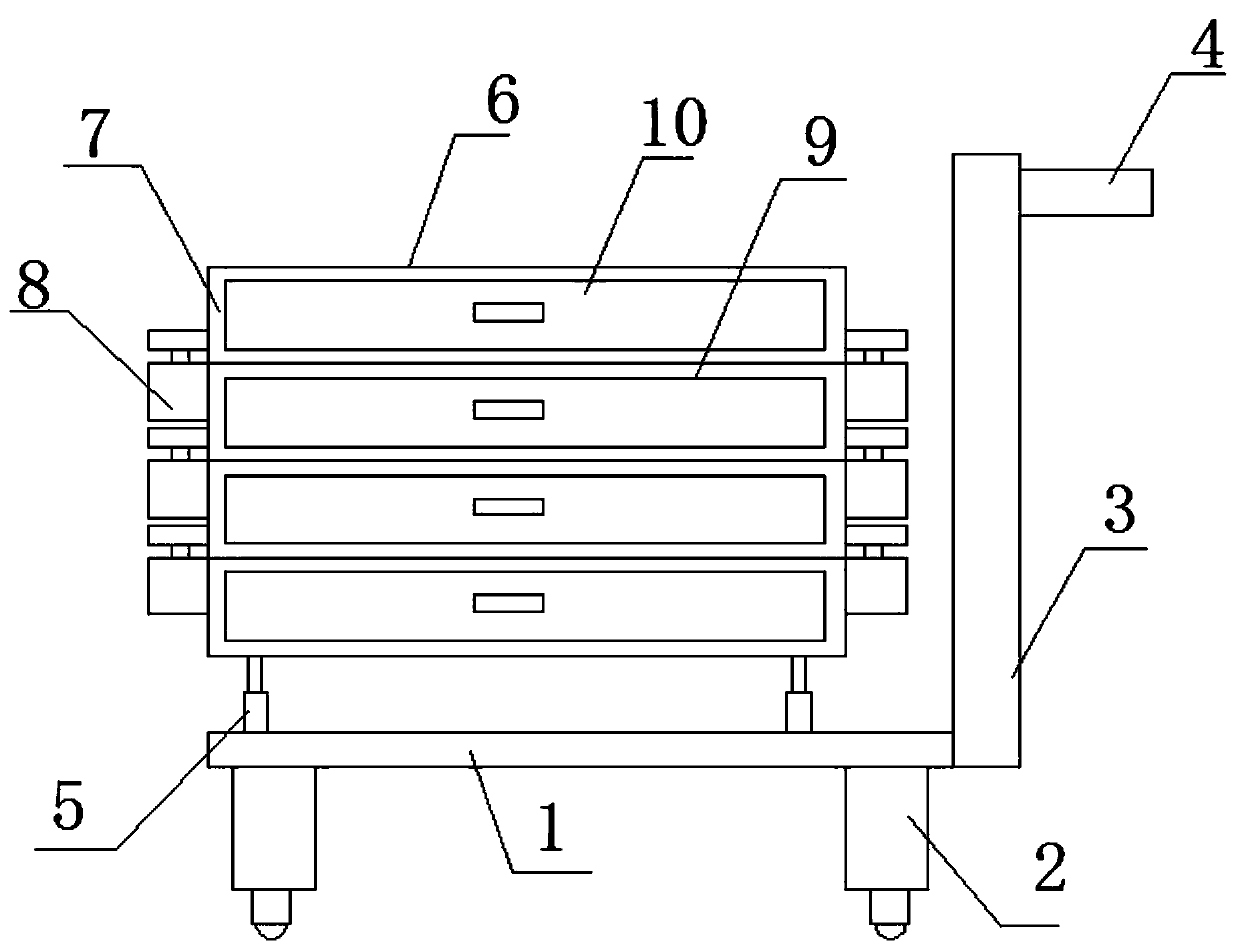

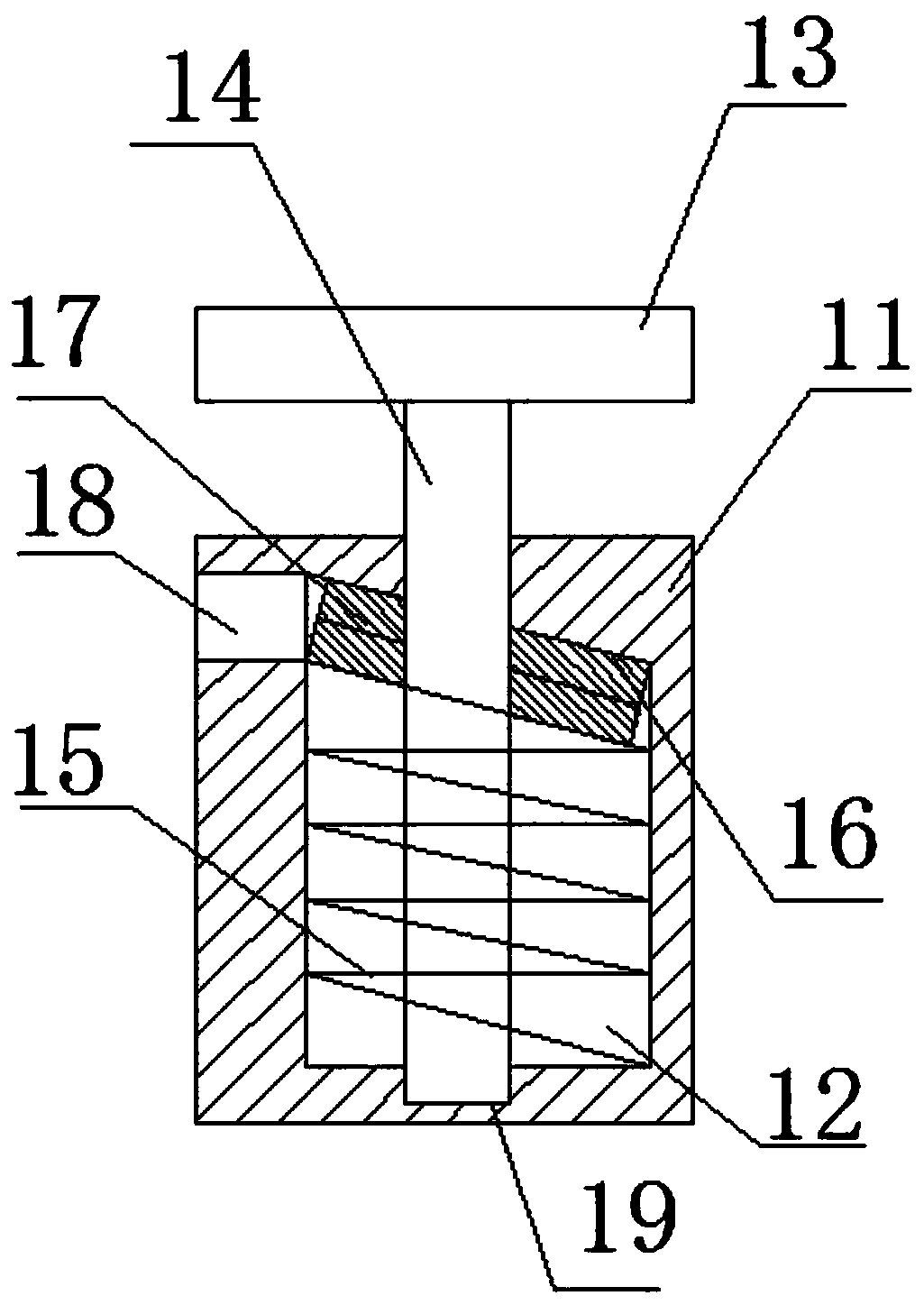

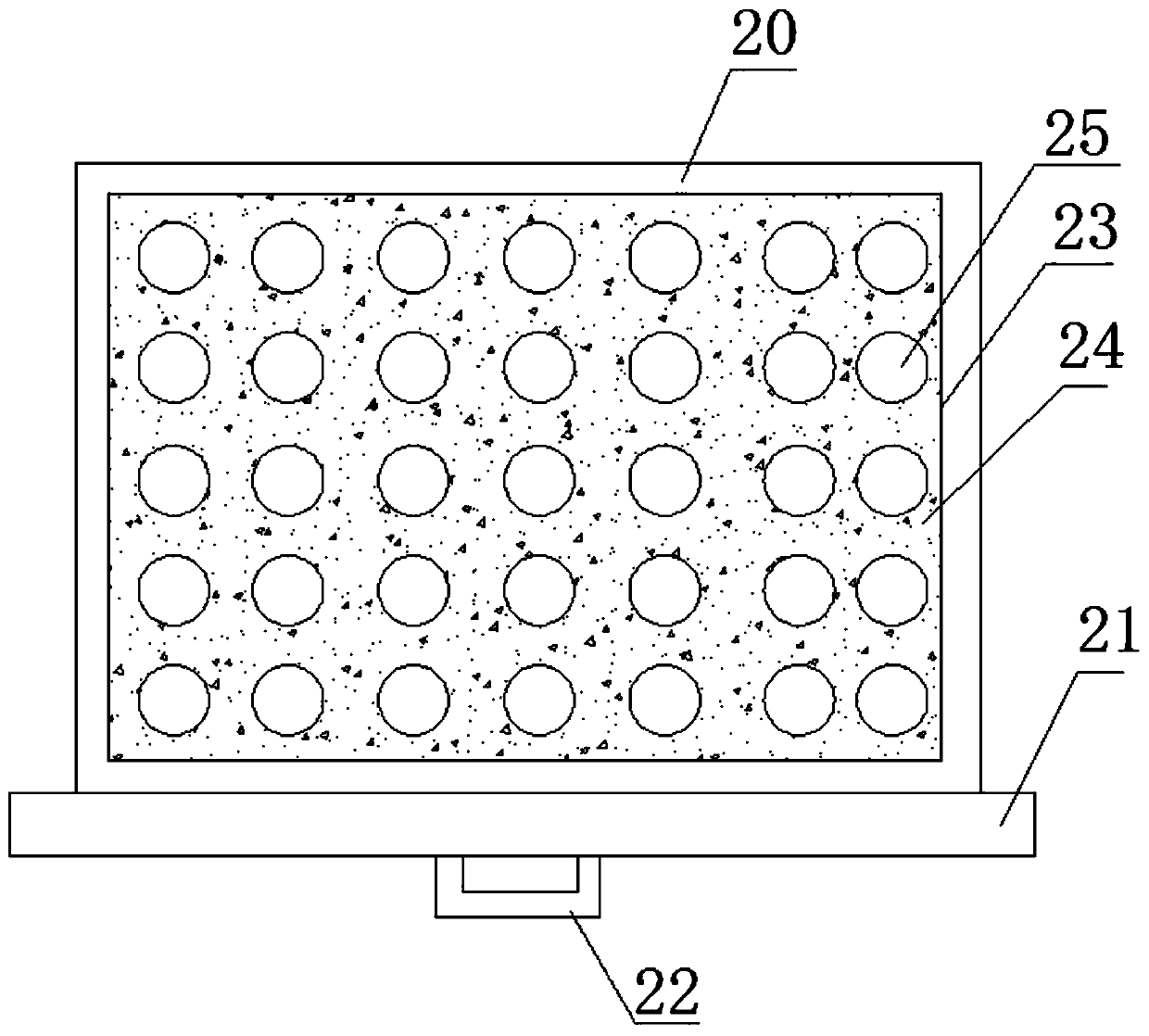

[0026] see Figure 1-4 , in an embodiment of the present invention, a high-voltage power capacitor porcelain bottle transfer device includes a base 1, a running mechanism 2 is provided on the underside of the base 1, a bracket 3 is provided on the upper right end of the base 1, and a bracket 3 is provided on the bracket 3. There is a push rod 4, and the upper side of the base 1 is provided with several first electric telescopic mechanisms 5, and the upper end of the first electric telescopic mechanism 5 is equipped with a transfer mechanism 6, and the transfer mechanism 6 is composed of several transfer seats 7, and the transfer seat 7 is provided with a cavity 9, and the cavity 9 is provided with a storage drawer 10, and the adjacent transfer seats 7 are connected by a connecting mechanism 8, and the connecting mechanism 8 includes a connecting seat 11 and a connecting plate 13. The connecting plate 13 and the connecting seat 11 are respectively installed on the two adjacent ...

Embodiment 2

[0029] On the basis of embodiment one, refer to Figure 4 , the walking mechanism 2 includes a leg 26, the inside of the leg 26 is provided with a housing cavity 27, and the inside of the housing cavity 27 is provided with a shock-absorbing support mechanism, and the shock-absorbing support mechanism includes a The shock absorbing mechanism 28 on the cavity 27, the lower end of the shock absorbing mechanism 28 is provided with a shock absorbing plate 29 that is slidably connected with the accommodation cavity 27, and the lower side of the shock absorbing plate 29 is provided with a supporting walking mechanism. The running mechanism includes a second electric telescopic mechanism 30 installed on the shock absorbing plate 29, the lower end of the second electric telescopic mechanism 30 is equipped with a support seat 31 which is slidingly connected with the accommodating cavity 27, and the lower side of the support seat 31 A universal wheel 32 is provided, and a locking mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com