A rotary wing elevator

A hoist and rotary wing technology, which is applied to cranes, load hanging components, electrical components, etc., can solve the problems of bracket tilt, affecting the stability of rotary wing hoists, and obstacles to hoisting and lifting of electrical equipment, so as to prevent hoisting and lifting, The effect of preventing drift and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

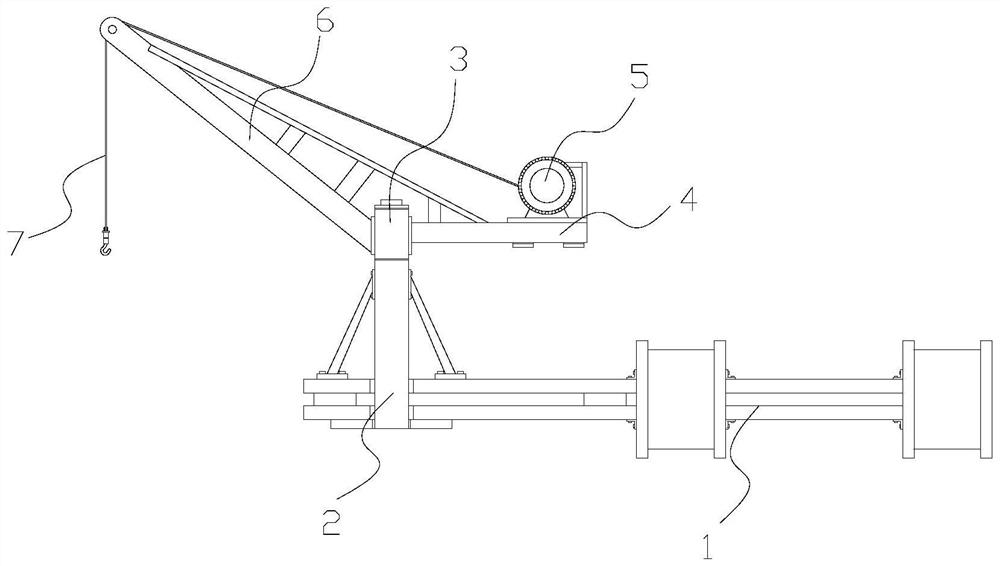

[0030] Example 1: Please refer to Figure 1-Figure 8 , the specific embodiments of the present invention are as follows:

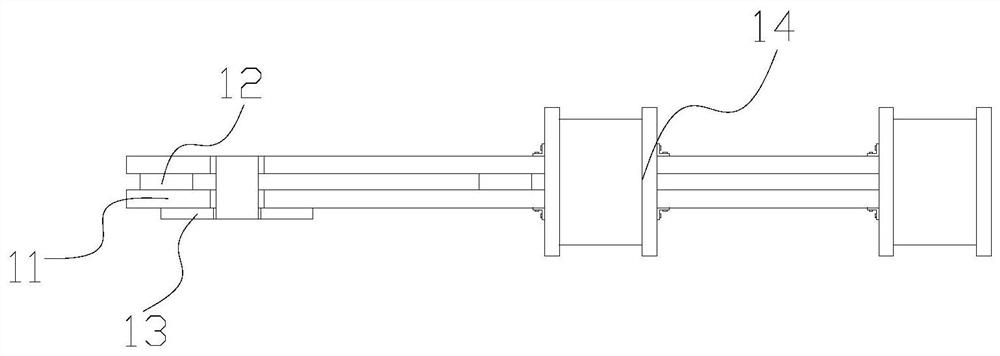

[0031] Its structure includes a mounting and fixing structure 1, a support column 2, a rotating seat 3, a bracket 4, a motor 5, a hanger 6, and a suspension cable 7. The support column 2 is vertically installed on the upper end of the installation and fixing structure 1 and is mechanically connected. The swivel base 3 is embedded and installed on the upper end of the supporting column 2 and connected by a hinge, the bracket 4 is horizontally installed on the right side of the swivel base 3 and welded, the motor 5 is fixed to the upper end of the bracket 4 by bolts, and the hanger 6 is tilted Installed on the left side of the swivel base 3, the suspension cable 7 bypasses the hanger 6 and is connected to the motor 5; A spacer 12 is connected between the frames 11, the fixed plate 13 is horizontally installed on the lower end of the connecting frame 11, the...

Embodiment 2

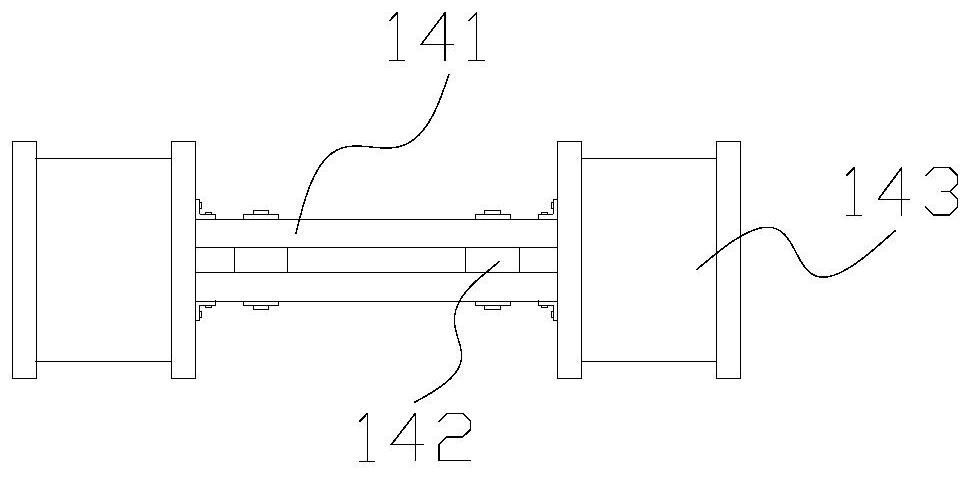

[0039] Example 2: Please refer to Figure 5-Figure 6 , Figure 9-Figure 10 , the specific embodiments of the present invention are as follows:

[0040] The activity limiting structure 143 includes a side plate 43a, a rolling structure 43b, and a fixing structure 43c. The rolling structure 43b is embedded and installed inside the side plate 43a, and the fixing structure 43c is arranged and welded between the side plates 43a.

[0041] refer to Figure 6 The rolling structures 43b are provided in multiples and every group of four is evenly distributed inside the side plates 43a, the fixed structure 43c separates the two side plates 43a, stabilizes the side plates 43a, and then moves better to adjust the height.

[0042] refer to Figure 9 , the fixed structure 43c includes a limiting plate c1, an adjusting rod c2, a spacer structure c3, and a slot c4. Between the plates c1, the clamping groove c4 is set on the inner side of the limiting plate c1 and is an integrated structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com