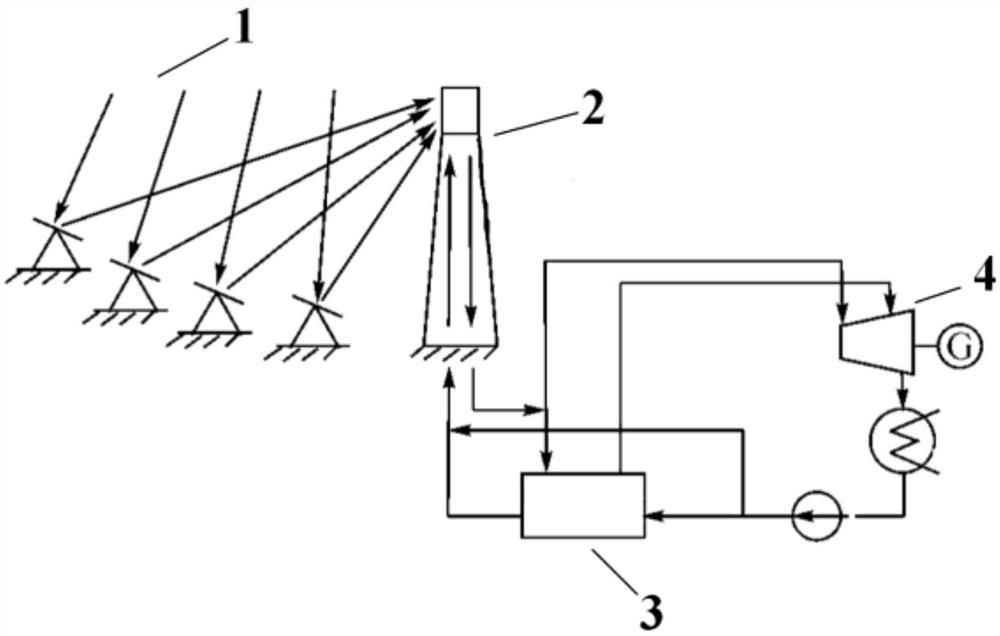

Solar thermal power generation absorption/heat storage integrated corundum/sic ceramic material and preparation method thereof

A technology for solar thermal power generation and ceramic materials, which is applied in the field of solar thermal power generation absorption/heat storage integrated corundum/SiC ceramic materials and their preparation, can solve the problems of low thermal conductivity and low strength, and achieves high thermal conductivity, high Strength and high temperature resistance, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the solar thermal power generation / heat storage integrated corundum / SiC ceramic material provided in the first embodiment includes the following steps:

[0034] 1) Raw material processing: mill SiC, corundum and kaolin with a fast ball mill for 1 to 3 hours respectively to obtain graded SiC powder, corundum powder, kaolin powder and borax for later use;

[0035] 2) Proportion and mixing of raw materials: according to the mass percentage of each raw material: 50% of SiC powder, 40% of corundum powder, 10% of kaolin powder, 1% of borax, weigh the raw materials, and mix them with a fast ball mill for 1 to 3 hours to obtain a mixed material;

[0036] 3) Granulation and aging: granulation is carried out by spray granulation method, wherein the amount of water added is 5-10% of the mass of the mixture, and then aged for 24-36 hours to obtain a billet;

[0037] 4) Molding: use a hydraulic press to press and shape the stale billet to obtain a green bi...

Embodiment 3

[0051] The preparation method of the integrated corundum / SiC ceramic material for solar thermal power generation and heat storage provided in Example 3 includes the following steps:

[0052] 1) Raw material processing: mill SiC, corundum and kaolin with a fast ball mill for 1 to 3 hours respectively to obtain graded SiC powder, corundum powder, kaolin powder and borax for later use;

[0053] 2) Proportion and mixing of raw materials: according to the mass percentage of each raw material: 90% of SiC powder, 5% of corundum powder, 5% of kaolin powder, 1% of borax, weigh the raw materials, and mix them with a fast ball mill for 1 to 3 hours to obtain a mixed material;

[0054] 3) Granulation and aging: granulation is carried out by spray granulation method, wherein the amount of water added is 5-10% of the mass of the mixture, and then aged for 24-36 hours to obtain a billet;

[0055] 4) Molding: use a hydraulic press to press and shape the stale billet to obtain a green billet;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap