Low ceiling lamp

A ceiling lamp and accommodating cavity technology, which is applied in the direction of lighting devices, fixed lighting devices, electric light sources, etc., can solve the problems of large volume and inconvenient assembly and disassembly of low ceiling lamps, and achieve the effects of simple structure of lamps, convenient assembly and disassembly, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

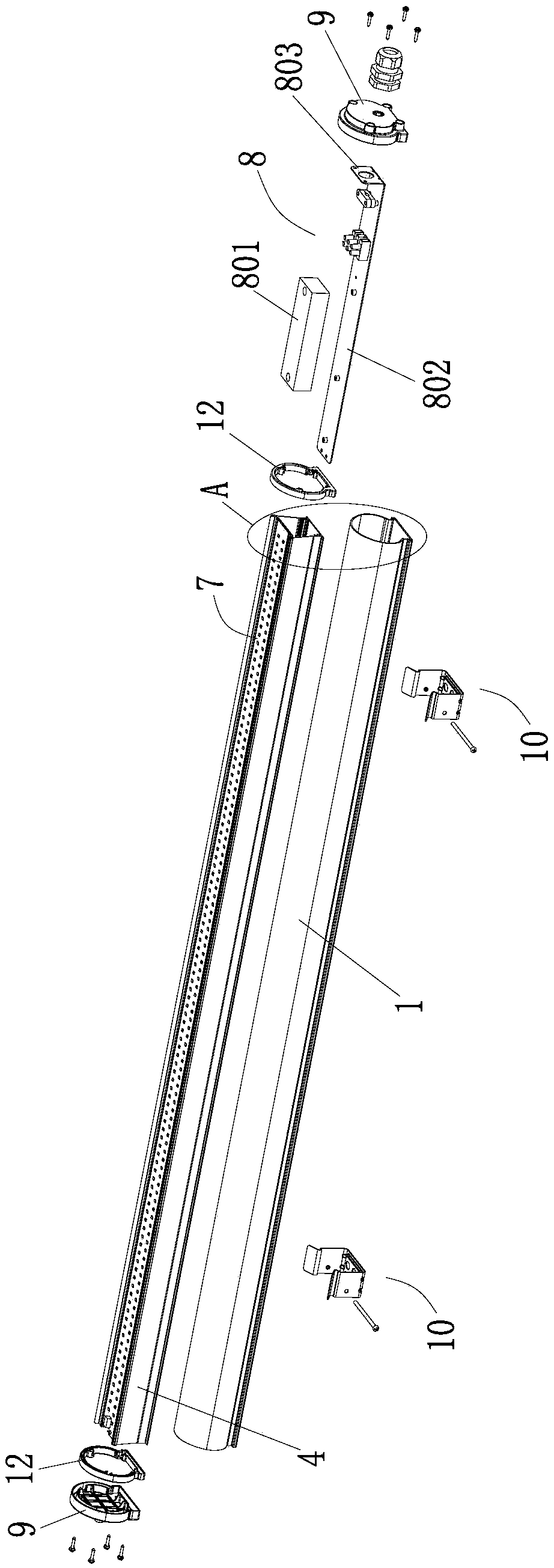

[0036] refer to figure 1 , Figure 9 and Figure 10 , as a specific embodiment of the low dome light provided by the present invention, the drive mounting plate includes a first plate body 802 for connecting with the driver 801 and is arranged at the outer end of the first plate body 802 and is perpendicular to the first plate body 802 The second plate body 803; the second plate body 803 is provided with a plate body installation hole 14, and the end cover 9 is provided with an end cover screw hole 15 corresponding to the plate body installation hole 14; the end cover 9 is provided with an end cover wire The second board body 803 is provided with a board cable passage hole 17 corresponding to the cable passage hole 16 of the end cover. The drive mounting plate is bent in an L shape, which is convenient for connecting with the drive 801 and the end cover 9 respectively, and can effectively reduce the space occupied by the drive assembly 8 .

[0037] see figure 1 and Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com