Polarized light 3D image measuring mechanism and manufacturing method thereof

A technology of image measurement and manufacturing methods, applied in optical radiation measurement, measuring light polarization, optics, etc., can solve problems such as large volume and mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

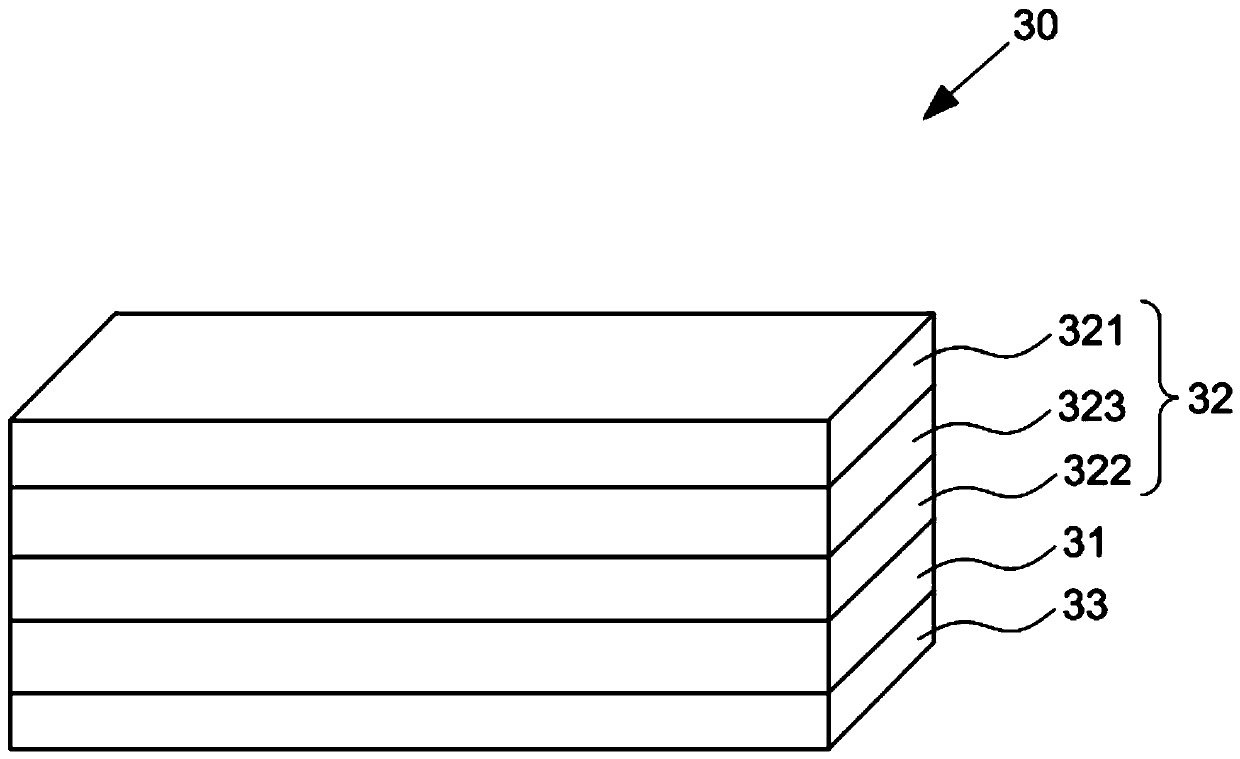

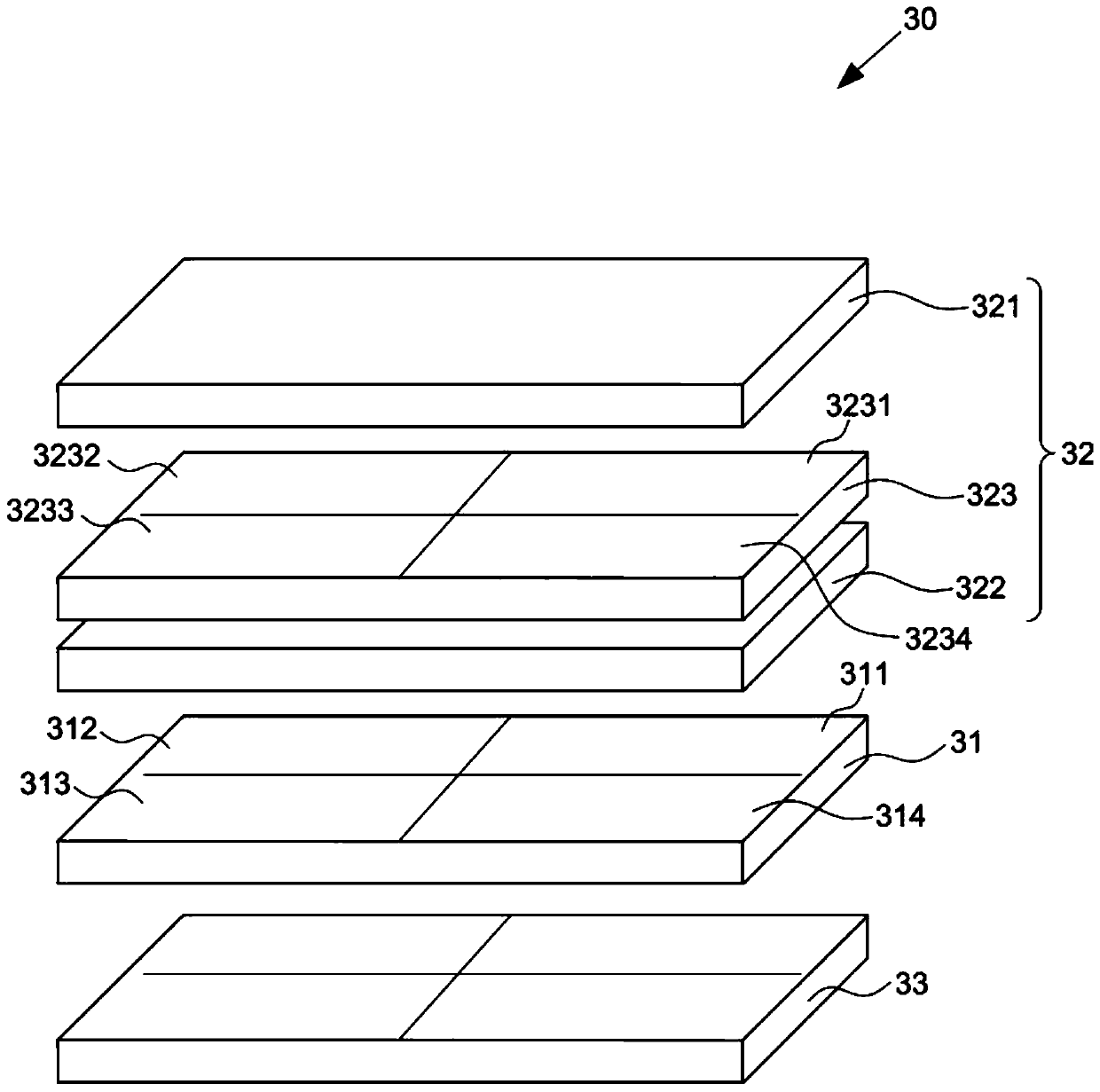

[0044] The present invention relates to a "mechanism for measuring polarized 3D images and its manufacturing method", please refer to figure 2 with image 3 As shown, the polarized 3D image measurement mechanism 30 of the present invention mainly includes: a polarizer 31, a liquid crystal cell 32, and an image sensor 33.

[0045] Wherein, the polarizer 31 is disposed on the image sensor 33, and the polarizer 31 distinguishes at least four quadrants, including a first quadrant 311, a second quadrant 312, a third quadrant 313, and a fourth quadrant 314 , Wherein the polarization axis angle Θ of the first quadrant 311 is 90 degrees, the polarization axis angle Θ of the second quadrant 312 is 0 degrees, the polarization axis angle Θ of the third quadrant 313 is 45 degrees, and the The polarization axis angle Θ of the four-quadrant 314 is 45 degrees.

[0046] The liquid crystal cell 32 is arranged on the polarizing plate 31 so that the polarizing plate 31 is sandwiched between the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com