Bolt clamping force testing device

A testing device and clamping force technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem of not finding a clamping device, and achieve the effect of easy operation and high simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

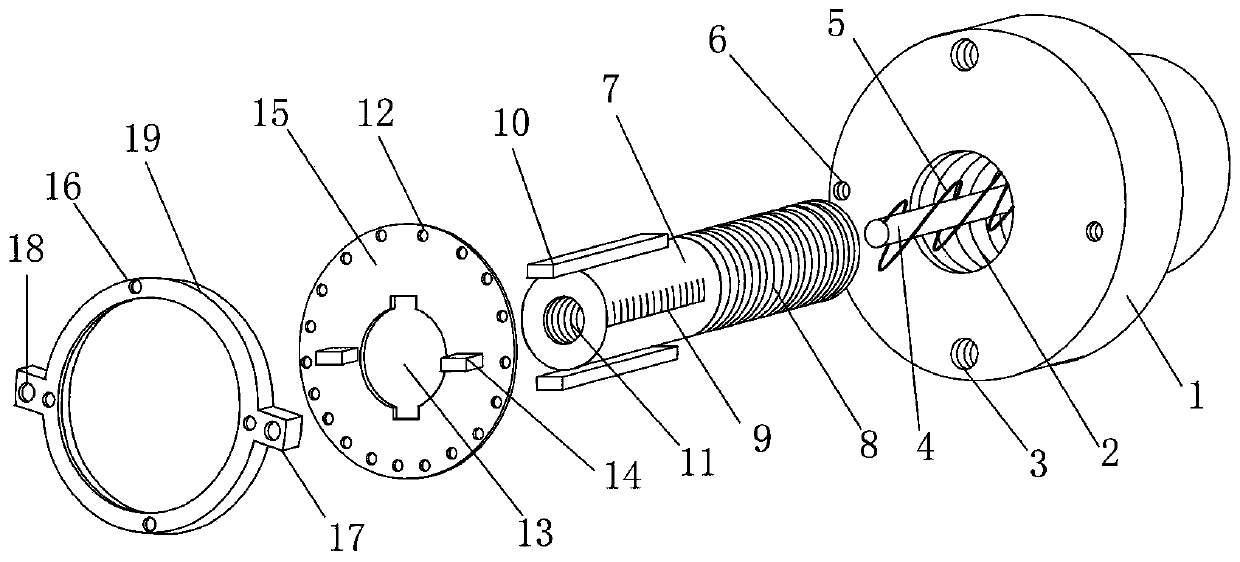

[0014] Such as figure 1 As shown, a bolt clamping force testing device includes a sensor connector 1, a clamping threaded roller 7, a connecting rotating disc 15, and a compression sleeve 19; the central axis of the sensor connector 1 is provided with a threaded roller screw hole 2. The central axis of the screw hole 2 of the threaded roller is centered with a limiting rod 4 , and the bottom end of the limiting rod 4 is combined with the bottom end of the screw hole 2 of the threaded roller. The central axis of the clamping threaded roller 7 is provided with a clamping threaded hole 11, and the diameter of the clamping threaded hole 11 is not less than the diameter of the limiting rod 4, so that the limiting rod 4 can be clamped in the clamping thread in use. Relatively sliding in the hole 11; the outer wall of the clamping threaded roller 7 is provided with an adjusting thread 8 corresponding to the screw hole 2 of the threaded roller, and the adjusting thread 8 in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com