All-electric four-axis periodic cycle test bench and experimental method

A cyclic test, linear motor technology, applied in the field of test benches, can solve the problems of poor stability of the hydraulic system, high energy consumption, low hydraulic transmission efficiency, etc., and achieve the effect of small load changes, high transmission efficiency, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

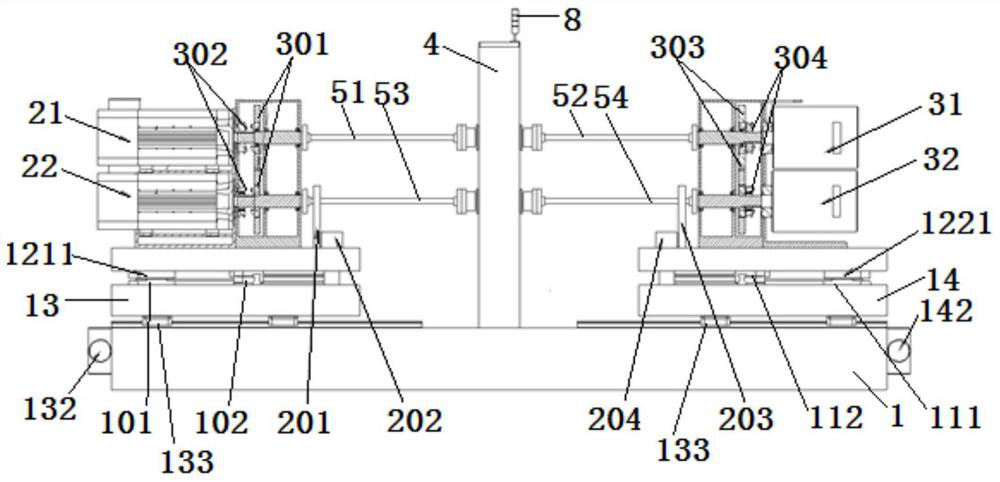

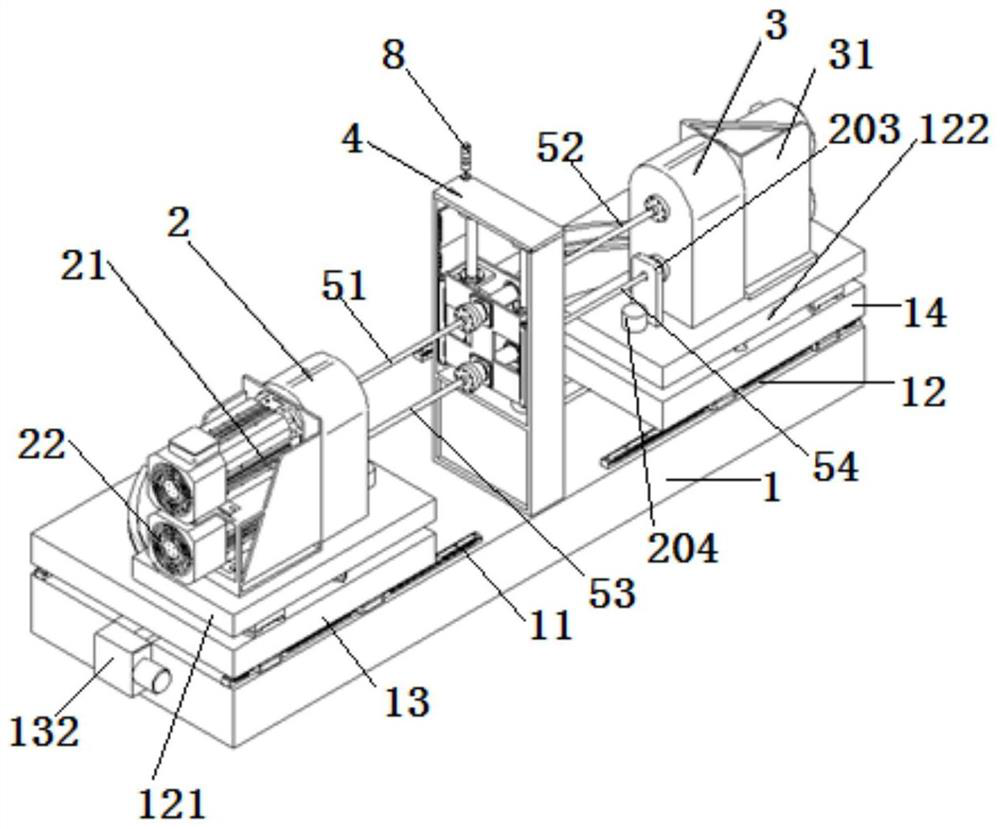

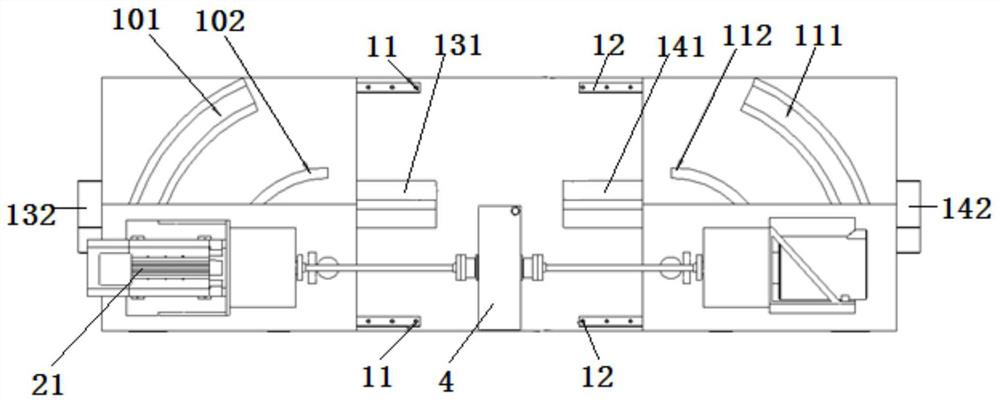

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 The illustrated embodiment is an all-electric four-axis periodic cycle test bench, comprising a base 1, two left transverse guide rails 11 arranged on the left part of the base, two right transverse guide rails 12 arranged on the right part of the base, arranged on The left sliding base 13 on the left side of the base, the right sliding base 14 located on the right side of the base, the left arc magnetic track 101 and the left arc guide rail 102 located on the left sliding base, the right arc located on the right sliding base Magnetic track 111 and right curved guide rail 112, the left swing base 121 that is connected with left curved magnetic track and left curved guide rail, the right swing base 122 that is connected with right curved magnetic track and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com