A method for restraining the deformation of existing cutting gravity retaining wall

A gravity-type retaining wall technology, applied in construction, artificial island, geometric CAD, etc., can solve the problems of low economy, regardless of the bearing capacity of existing road cutting gravity-type retaining walls, to improve economy and avoid demolition and reconstruction. , the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

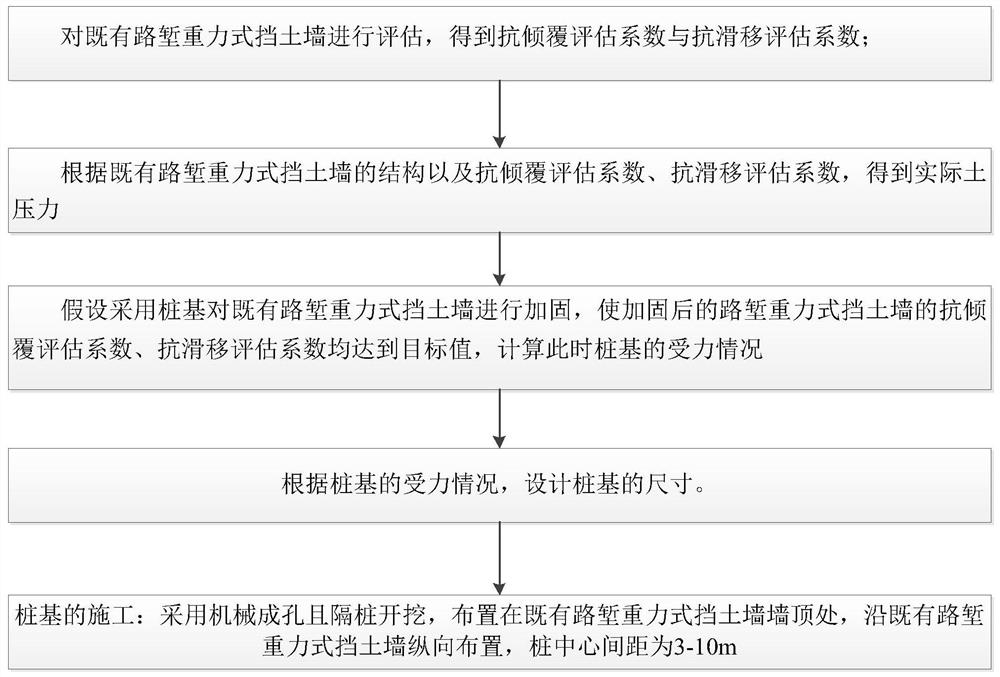

[0058] like figure 1 , a method for suppressing the deformation of an existing cutting gravity retaining wall 1, comprising:

[0059] S100 evaluates the existing cutting gravity retaining wall 1, and obtains the actual anti-overturning evaluation coefficient and the actual anti-slip evaluation coefficient;

[0060] S200 obtains the actual earth pressure according to the structural force of the existing cutting gravity retaining wall 1 and the actual anti-overturning evaluation coefficient and the actual anti-slip evaluation coefficient;

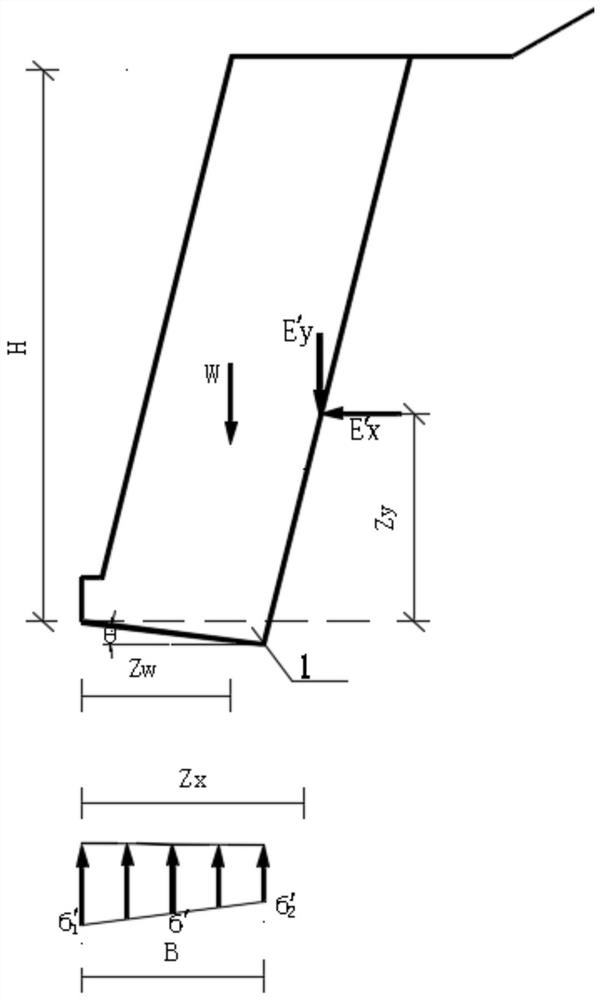

[0061] S300 assumes that pile foundations are used to reinforce the existing cutting gravity retaining wall 1, so that the target anti-overturning evaluation coefficient and target anti-sliding evaluation coefficient of the reinforced road cutting gravity retaining wall are used to calculate the stress condition of the pile foundation;

[0062] S400 designs the size of the pile foundation according to the stress condition of the pile foundat...

Embodiment 2

[0140] Step 1 Evaluation of existing cutting gravity retaining walls1

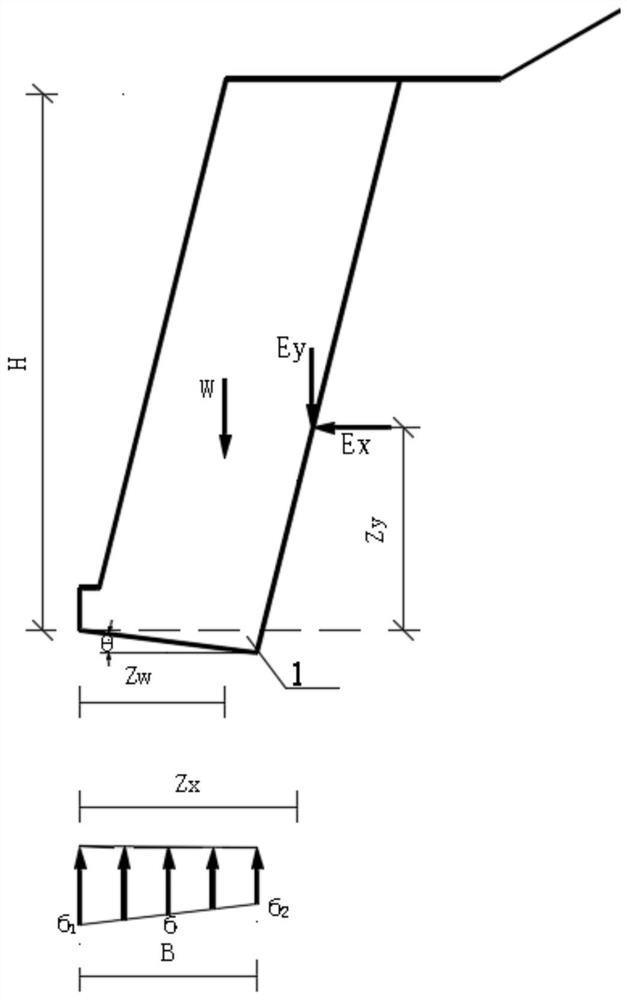

[0141] like Figure 7 , it is known that a single-line Class I railway has a cutting gravity retaining wall 1, the retaining wall is 6.0m high and 1.4m deep. The slope of the back slope is 1:-0.25, the width of the wall toe step is 0.25m, and the height of the wall toe step is 0.6m. is 0.3, see details for details Image 6 . The original design anti-overturning stability safety factor is 2.1847, and the original design anti-slip stability safety factor is 1.316.

[0142] According to the safety evaluation methods and means, the anti-overturning and anti-slip stability of the existing cutting gravity retaining wall 1 are evaluated, and the anti-overturning and anti-slip evaluation coefficients K are obtained respectively. 02 = 1.5 and K C2 = 1.1.

[0143] The second step is to calculate the actual earth pressure of the existing cutting gravity retaining wall 1

[0144] According to the original desig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap