A support tool and working method for avoiding intermediate deformation during wafer coating

A working method and wafer technology, applied in workpiece clamping devices, manufacturing tools, electrical components, etc., can solve problems that cannot be eliminated, affect process production, coating quality problems, etc., reduce or eliminate warpage, eliminate a A series of bad conditions, the effect of enhancing the quality of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

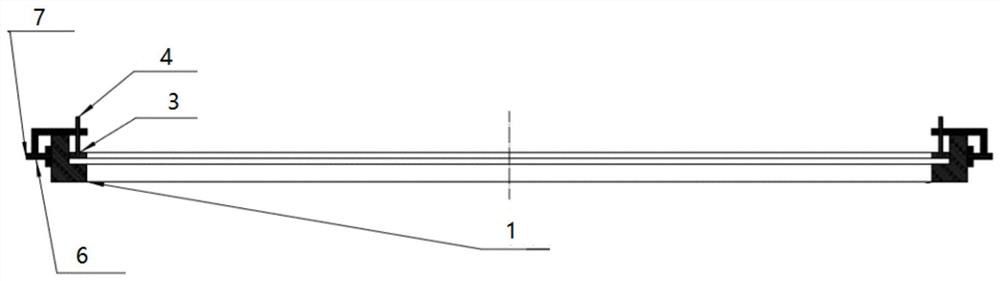

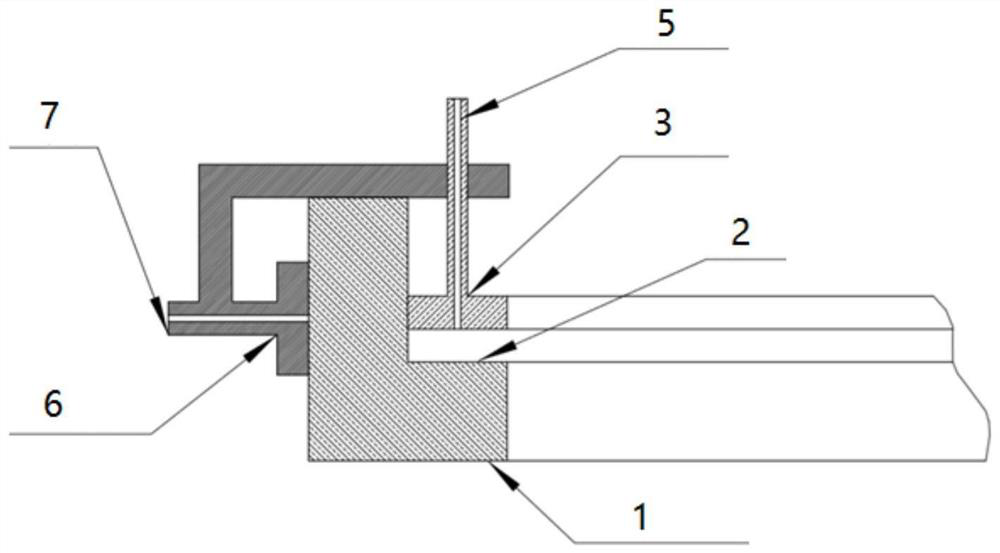

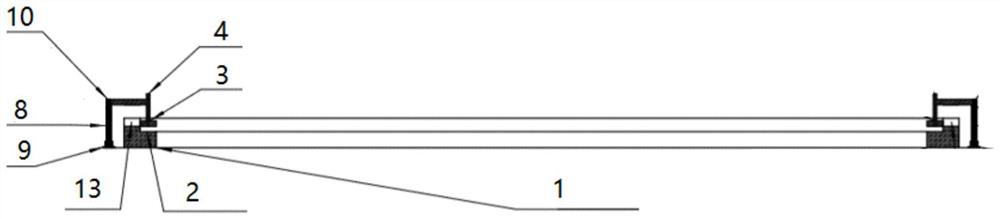

[0027] see figure 1 and figure 2 , the present invention includes a coating support 1, the coating support 1 is provided with a wafer placement platform 2, the wafer placement platform 2 and the coating support 1 form a ring-shaped step structure, and the top of the wafer placement platform 2 is provided with an upper suction cup 3, an upper suction cup 3 There are a number of suction cup columns 4 fixed on the top, at least one suction cup column 4 is provided with an upper suction cup vacuum channel 5, and the upper suction cup 3 is connected to a vacuum pump through the upper suction cup vacuum channel 5, and a side suction cup 6 is set on the suction cup column 4, and a side suction cup 6 is set on the side suction cup 6 There is a side suction cup vacuum passage 7, and the side suction cup vacuum passage 7 is connected with a vacuum pump.

[0028] When the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com