Method for shaping resistance variable nonvolatile memory element and resistance variable nonvolatile memory device

A non-volatile storage and resistance-variable technology, which is applied in the field of shaping of resistance-variable non-volatile memory elements and resistance-variable non-volatile memory devices, and can solve the problem of increasing the shaping voltage of resistance-changing elements and shaping voltage Deviation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

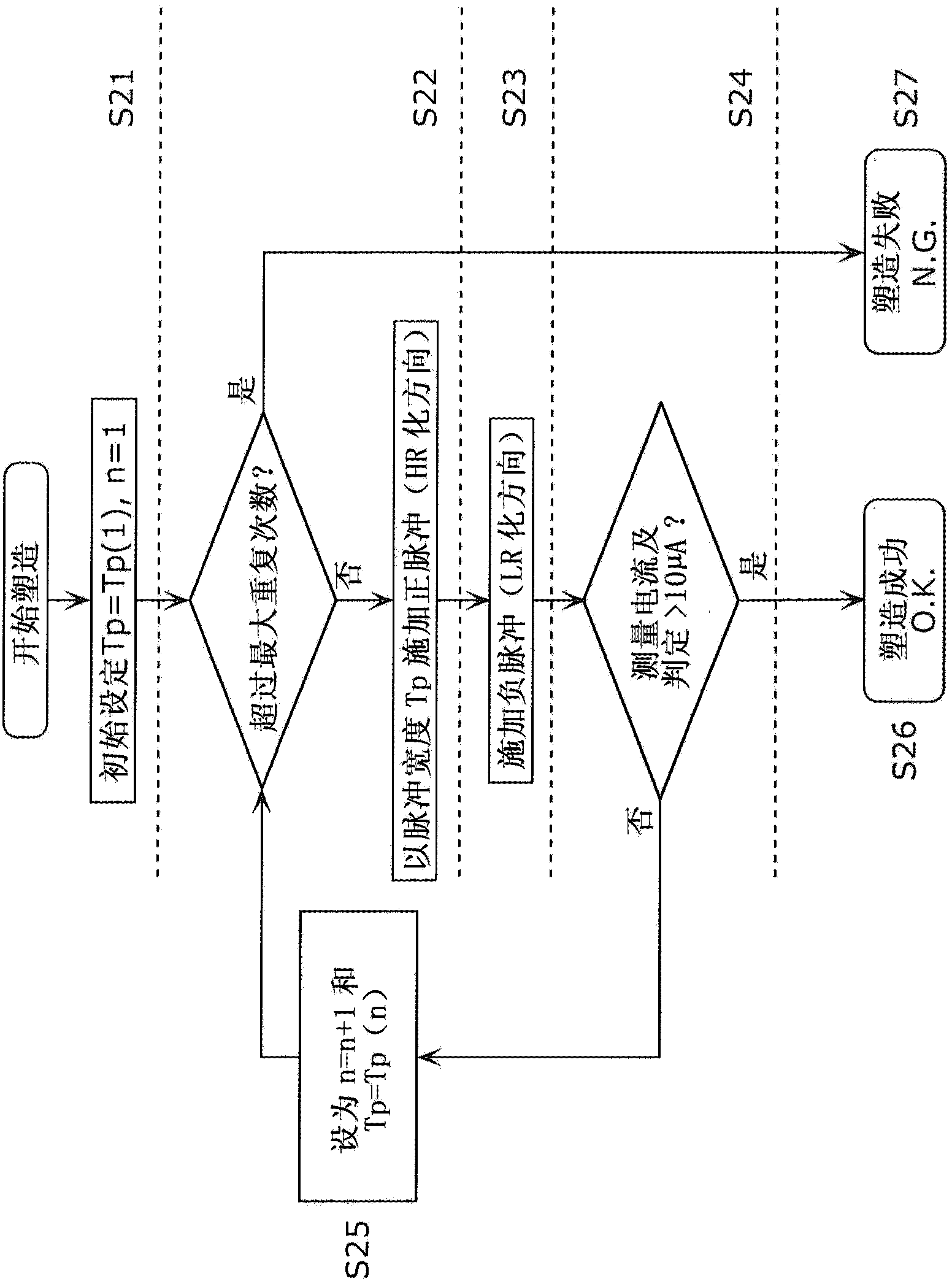

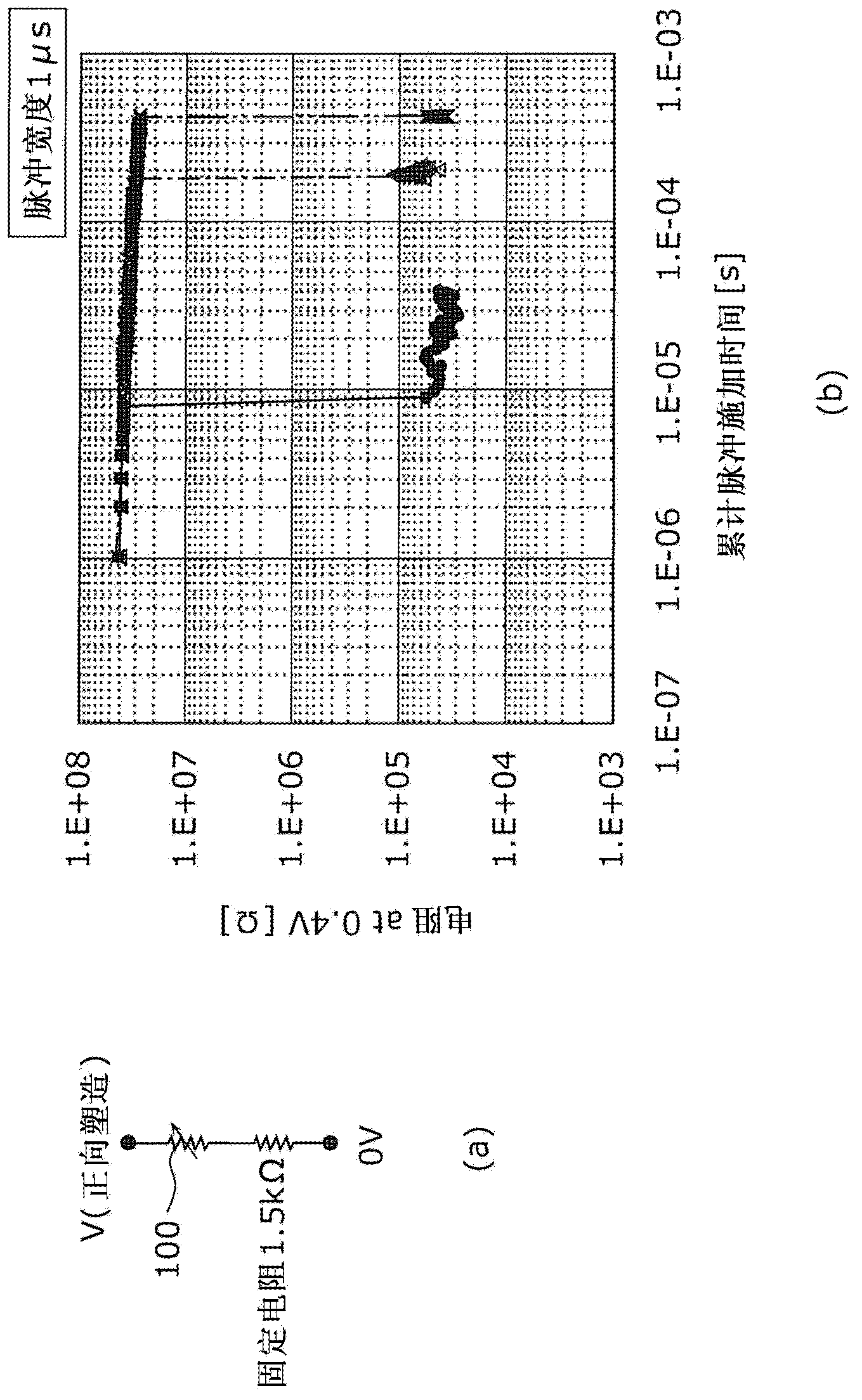

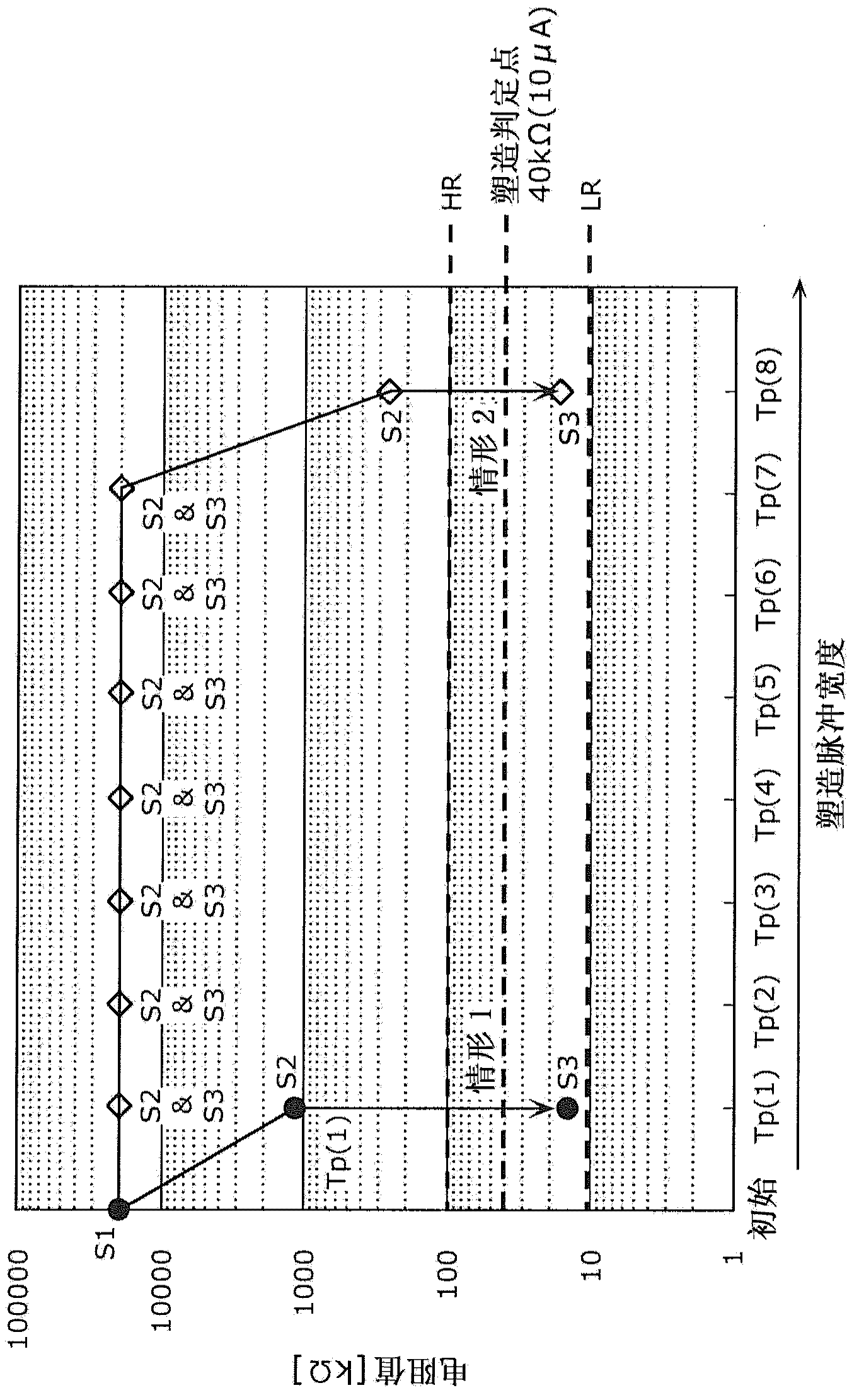

[0117] First, for Figure 29 The shown 1T1R type memory cell composed of a variable resistance element shows molding characteristics for the case where Pt (platinum) is used in the upper electrode 100c and the case where Ir (iridium) is used for the upper electrode 100c, And explain its technical problems, wherein the variable resistance element is composed of the first transition metal oxide layer 100b-1 (here, TaO x , 0y , x<y) to form.

[0118] Here, in the sample used in the experiment, the area of the variable resistance layer 100b is 0.25 μm 2 (=0.5μm×0.5μm), having a first transition metal oxide layer 100b-1 (here, TaO x : X=1.54, film thickness: 44.5nm), and the second transition metal oxide layer 100b-2 (here, TaO y : y=2.47, film thickness: 5.5 nm). The NMOS transistor serving as a switching element has a gate width W: 0.44 μm, a gate length L: 0.18 μm, and a gate insulating film thickness Tox: 3.5 nm.

[0119] The second transition metal oxide layer 100b-2 (h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com