Vertical brush of car washer

A car washing machine and vertical brush technology is applied in the field of car washing machines to achieve the effects of ensuring smooth lifting, improving cleaning performance, and improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

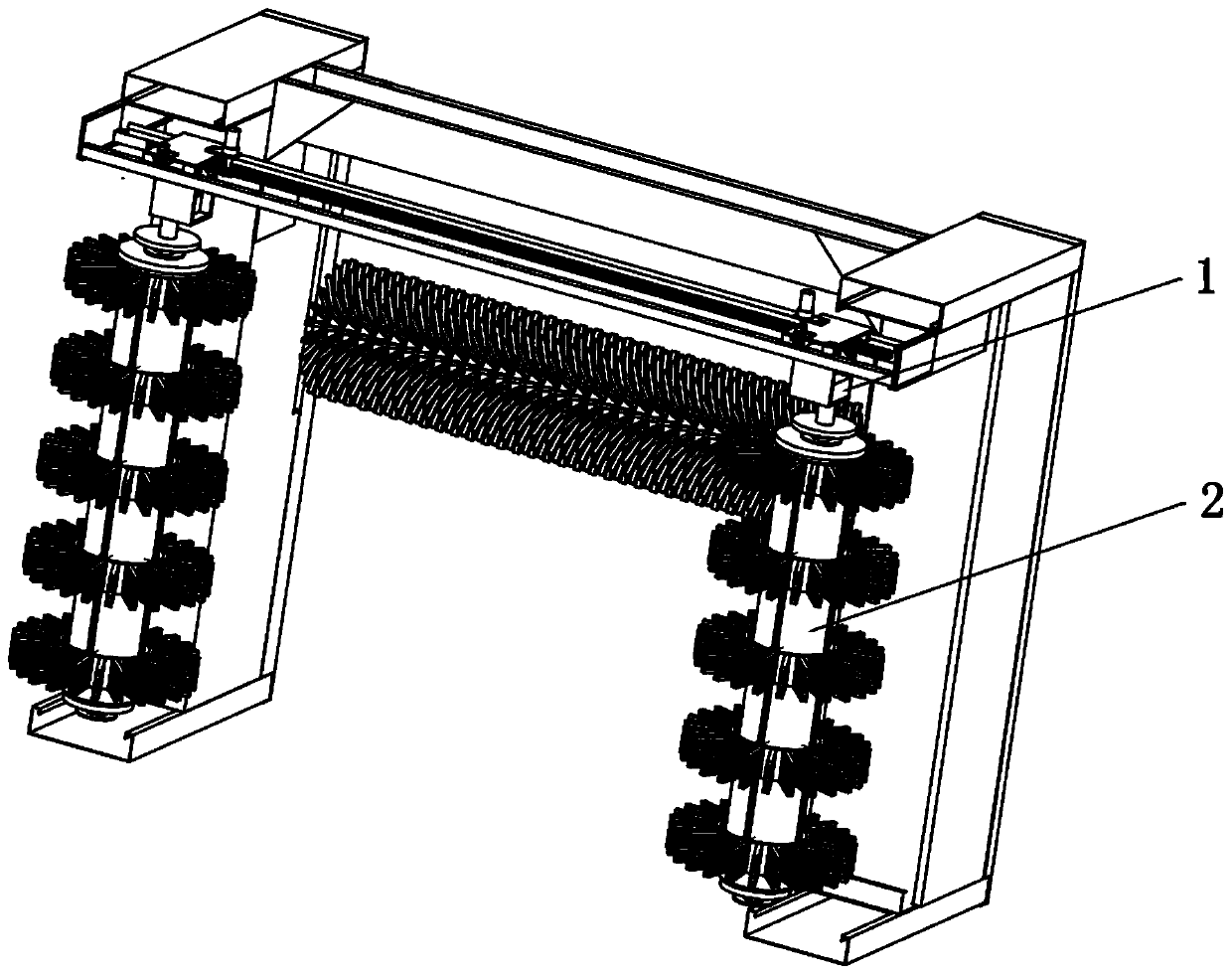

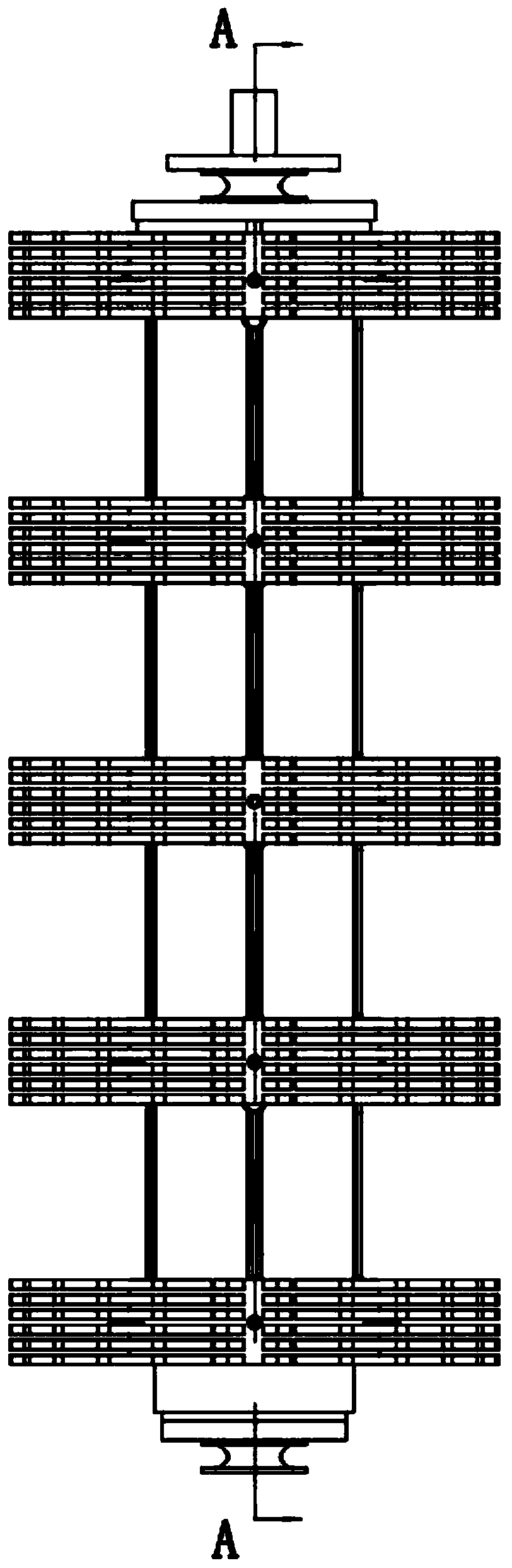

[0028] A kind of vertical brush of car washing machine, refer to Figure 1-Figure 5 As shown, it includes a vertically arranged rotating roller, a cleaning brush assembly arranged on the outer ring wall of the rotating roller to rotate synchronously with the rotating roller, and a servo motor 1 that drives the rotating roller to rotate.

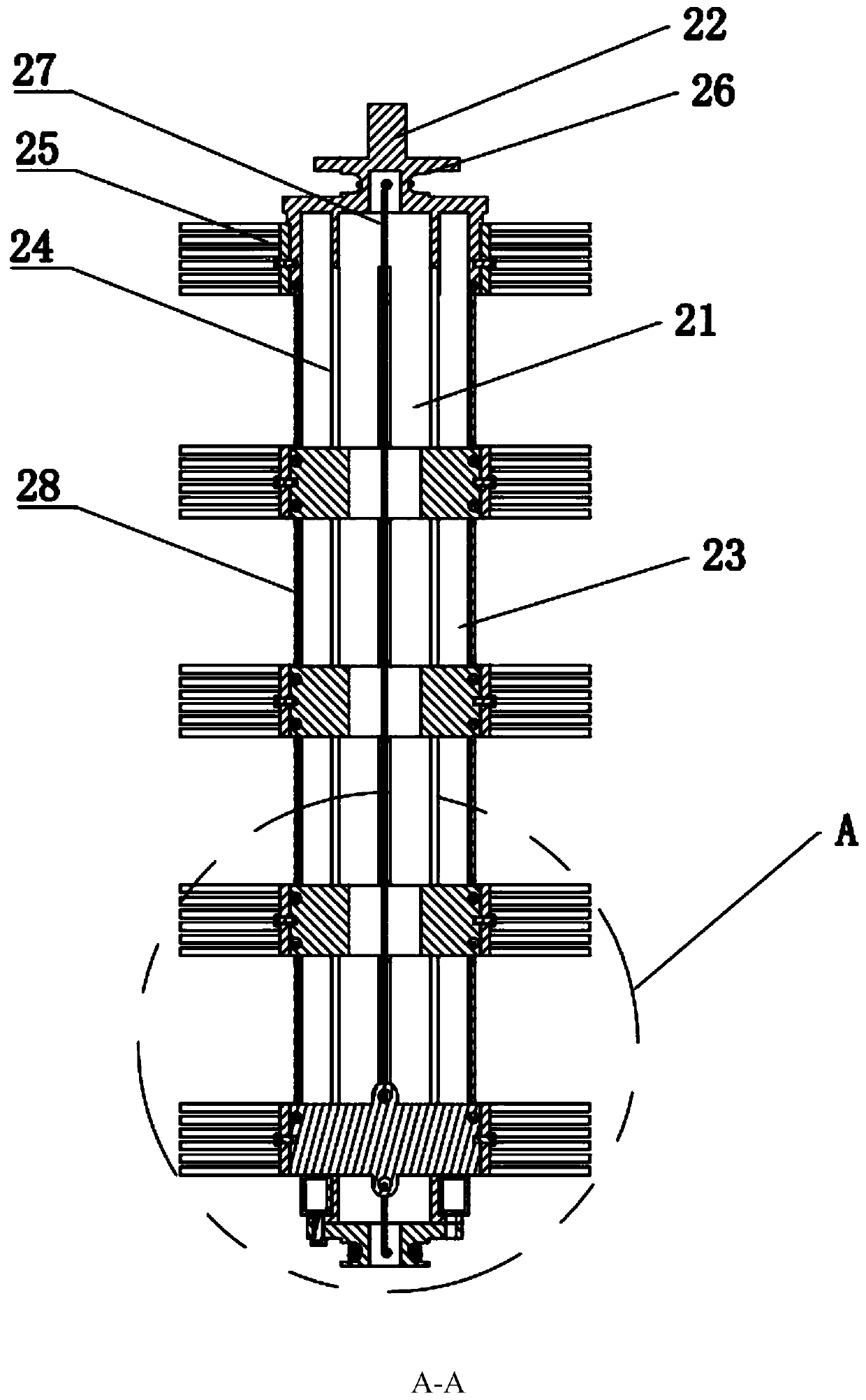

[0029] Refer to the specific structure of the rotating roller Figure 2-Figure 5 As shown, it includes a hollow roller body 21 and a rotating shaft 22 whose upper end of the roller body 21 is fixed with the motor shaft key of the servo motor 1. On the outer ring wall of the roller body 21, there are several directions distributed around the axial interval of the roller body 21. An axially extending guide channel of the roller body 21 .

[0030] Cleaning brush assembly specific reference Figure 3-Figure 4 As shown, it includes a number of lifting blocks distributed longitudinally at intervals inside the roller body 21, a guide block 212 int...

Embodiment 2

[0037] On the basis of embodiment 1, the improvement of this embodiment refers to Figure 3-Figure 5 As shown: a linkage connection structure is provided between adjacent guide blocks 212, and the linkage connection structure is a second stay rope 28 that is detachably arranged between the upper and lower guide blocks 212, and the opposite end of the guide block 212 is provided with a The threading holes 213 through which the two stay cords 28 pass.

[0038] The arrangement of the second pull cord 28 enables the adjacent cleaning brush bodies 25 to be in linkage connection, so the stuck phenomenon that may be caused by the driven lifting block 211 falling only by gravity can be avoided.

Embodiment 3

[0040] On the basis of embodiment 2, the improvement of this embodiment refers to Figure 3-Figure 4 As shown: an airbag layer 23 is provided on the outer ring wall of the roller body 21. After the airbag layer 23 is inflated, it fits or gaps with the fixed sleeve, and the airbag layer 23 is provided with an air nozzle for easy inflation or deflation.

[0041] Setting the airbag layer 23 can reduce the degree of damage caused by the vertical brush 2 or the car's operation error causing the car to directly contact the hard roller body 21 or avoid damage, and at the same time increase safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com