Lifting appliance capable of eliminating levelness deviation and being resistant to swing

A levelness and deviation technology, applied in the field of anti-swing spreaders, can solve the problems of limited reduction of levelness deviation, lack of anti-sway function, and decreased work efficiency, so as to improve stability, strong signal comprehensive processing ability, The effect of preventing the hanging object from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The hanger that can eliminate level deviation and resist swing provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

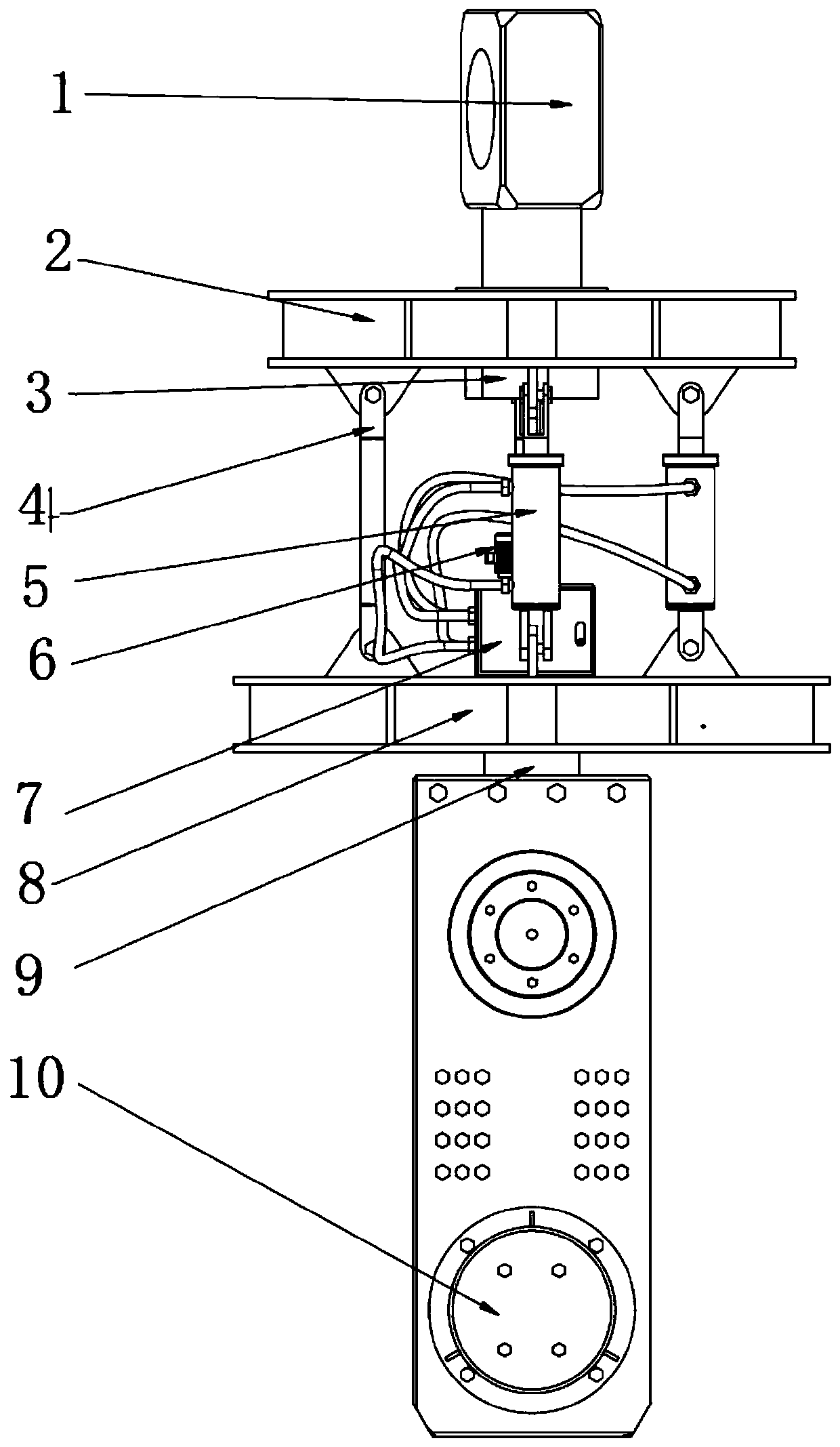

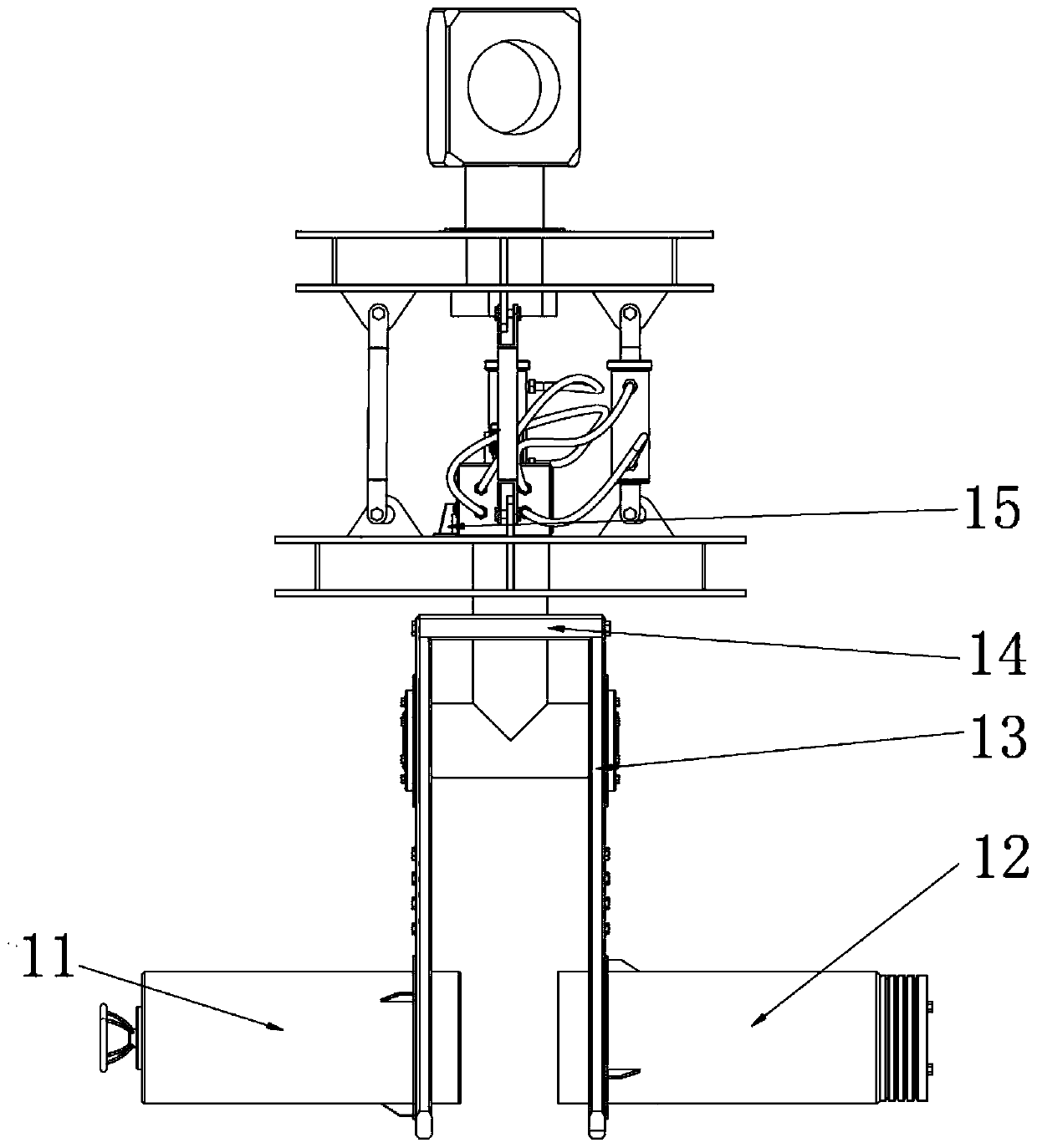

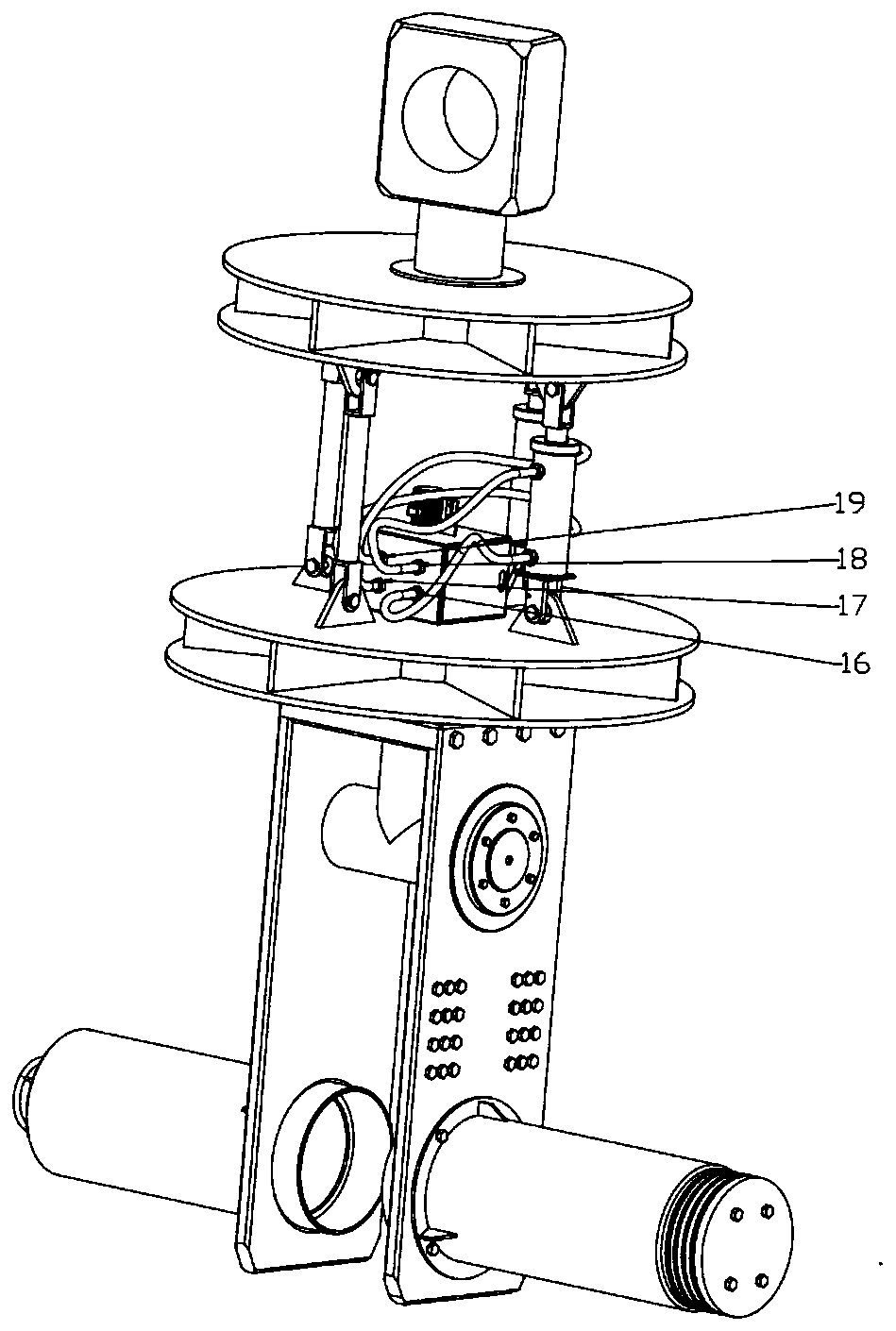

[0030] Such as Figure 1-3 As shown, the present invention provides a hanger capable of eliminating level deviation and anti-swing, including an actuator and a control system, wherein:

[0031] The actuator includes the upper lifting lug 1, the upper connecting piece 2, the lifting lug nut 3, the middle tie rod 4, the executive hydraulic cylinder 5, the lower connecting piece 8, the lower connecting shaft 9, the counterweight 10, the pin-through device 11, and the counterweight box 12 , the lower connecting plate 13, the lower connecting horizontal plate 14 and the fixed base 15 of the electric control box;

[0032] The upper lifting lug 1 is made of cast steel forging and machining, the upper end is processed with lifting lug holes, and the lower end is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com