Spinning process of cashmere blended yarn

A technology of blended yarn and blended yarn, applied in the direction of yarn, textile and papermaking, can solve the problems of uneven cashmere, easy generation of static electricity, affecting the wearing performance of clothing, etc., and achieve the effect of reducing damage and falling down and reducing hairiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

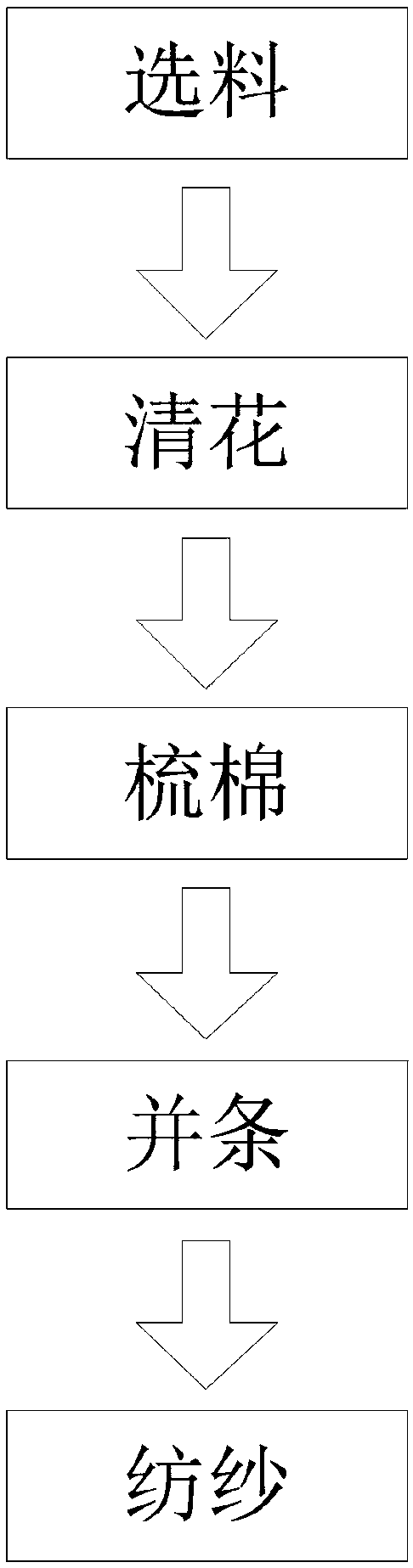

[0013] See figure 1 , figure 1 It is a structural schematic diagram of a spinning process of cashmere blended yarn provided by the present invention.

[0014] A kind of spinning process of cashmere blended yarn comprises:

[0015] Material selection, select the following raw materials in parts by weight: the mass ratio of cashmere to 50-60% of the blended yarn, 20-30% of the mass ratio of synthetic fiber to the blended yarn, and 20-30% of the mass ratio of viscose fiber to the blended yarn 15-20%;

[0016] For cleaning, the speed of the catching trolley is controlled at 540-680r / min, the speed of the beater of the cotton opener is controlled at 450-476r / min, the speed of the lapper is controlled at 700-710r / min, and the speed of the lapping roller is controlled at 450-476r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com