Vibration chamber flange plate and vibration mechanism of vibration wheel of extra-heavy vibratory roller

A technology of vibratory roller and vibrating mechanism, applied in the direction of road, road, road repair, etc., can solve the problems of poor operation safety and reliability, damage to other parts, easy damage of spline shaft, etc., so as to improve the cooling and lubrication effect and work reliably. , The effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

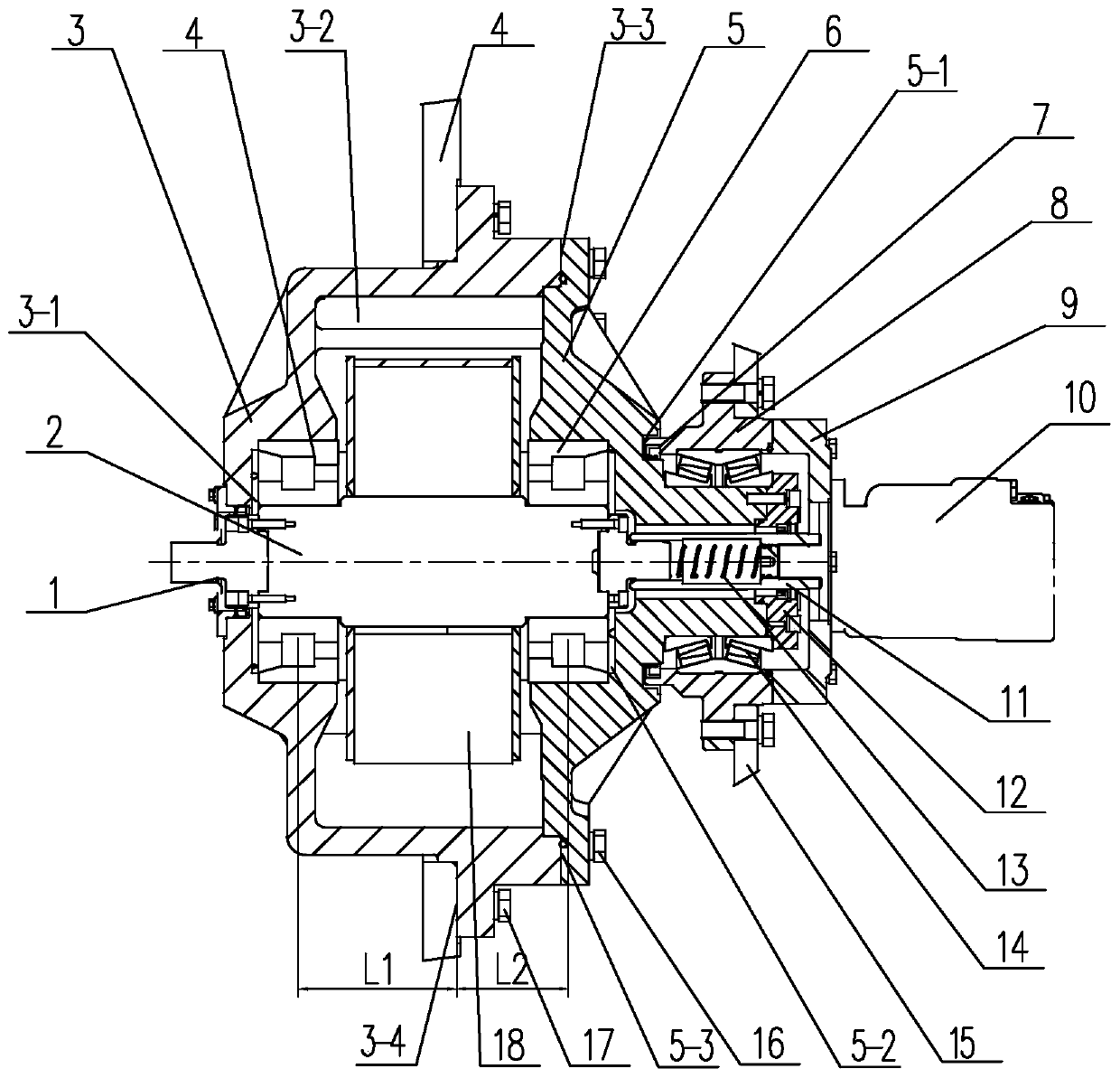

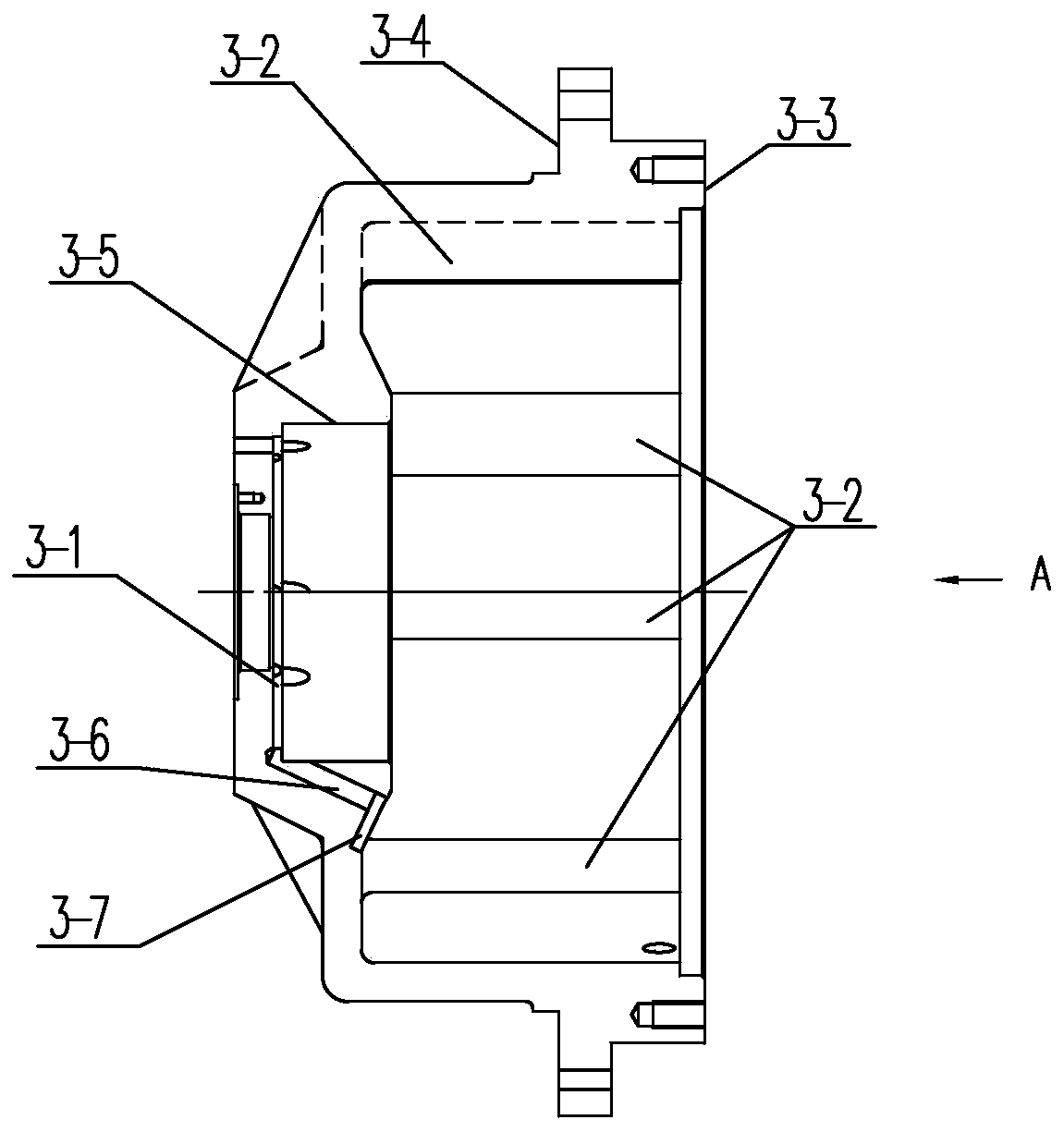

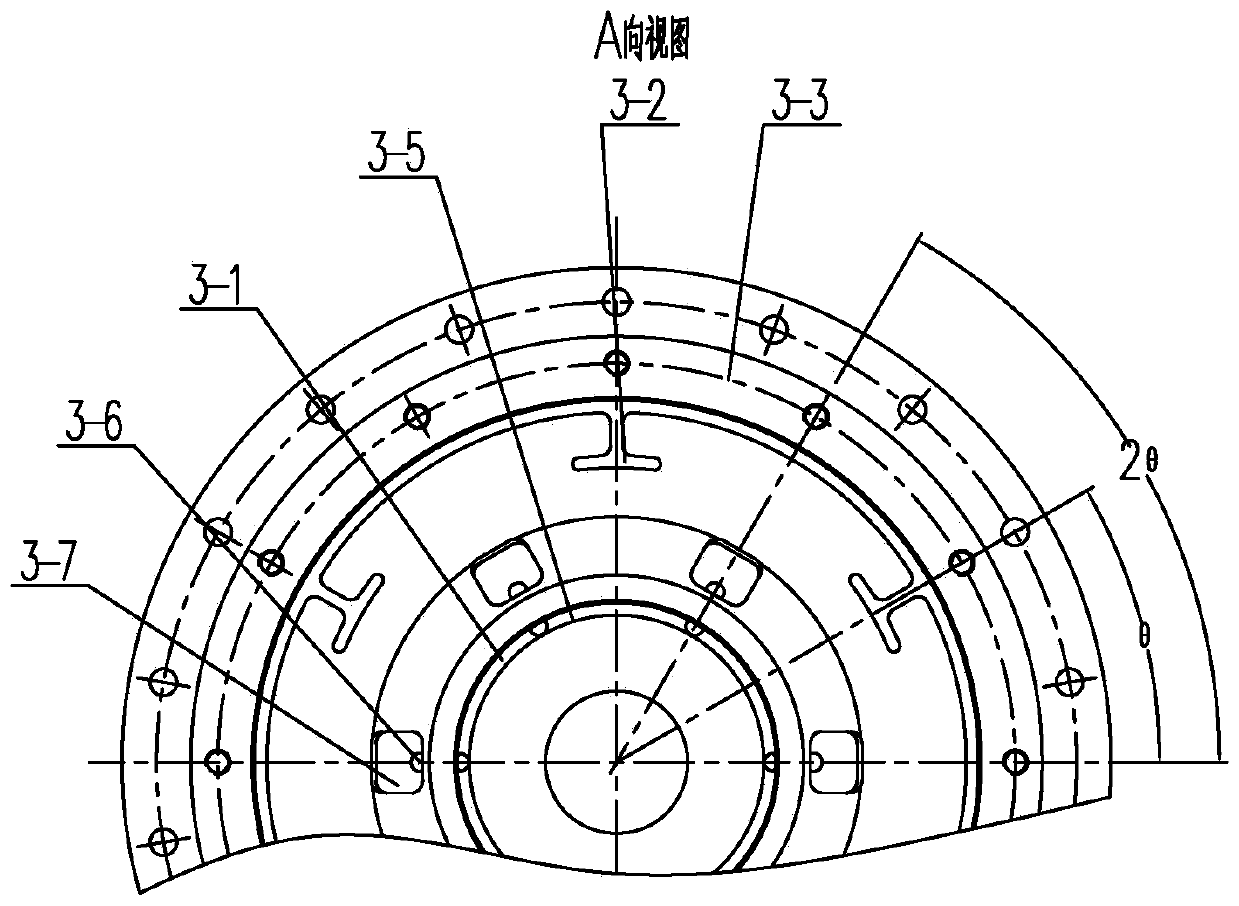

[0017] See Figure 1-6 As shown, the vibration chamber flange of the present invention includes an inner flange 3 provided with a first bearing hole 3-5 and an outer flange 5 provided with a second bearing hole 5-6, and the inner flange of the sealed connection The disc 3 and the outer flange 5 form a vibration chamber.

[0018] See Figure 1-6 As shown, the inner flange 3 of the present invention has an inner flange connection surface 3-4 connected to the vibrating spoke plate 4 and a stepped first joint surface 3-4 connected to the outer flange 5 with installation positions staggered. 3. Outer flange connection bolts 17 connect the inner flange 3 with the vibrating spoke plate 4, and connect the vibration chamber to the vibrating spoke plate 4 through the inner flange 3, since the outer flange 5 is no longer connected to the vibrating spoke plate 4 The spoke plate 4 is connected, so when the outer flange 5 is removed, the inner flange 3 is fixed on the vibrating spoke plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com