Bimetallic composite brake disc and manufacturing method thereof

A composite braking, bimetal technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problem of brake disc flange bottom cracking, affecting braking performance, cracking and other problems, reducing product The effect of wall thickness, improving service life and preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

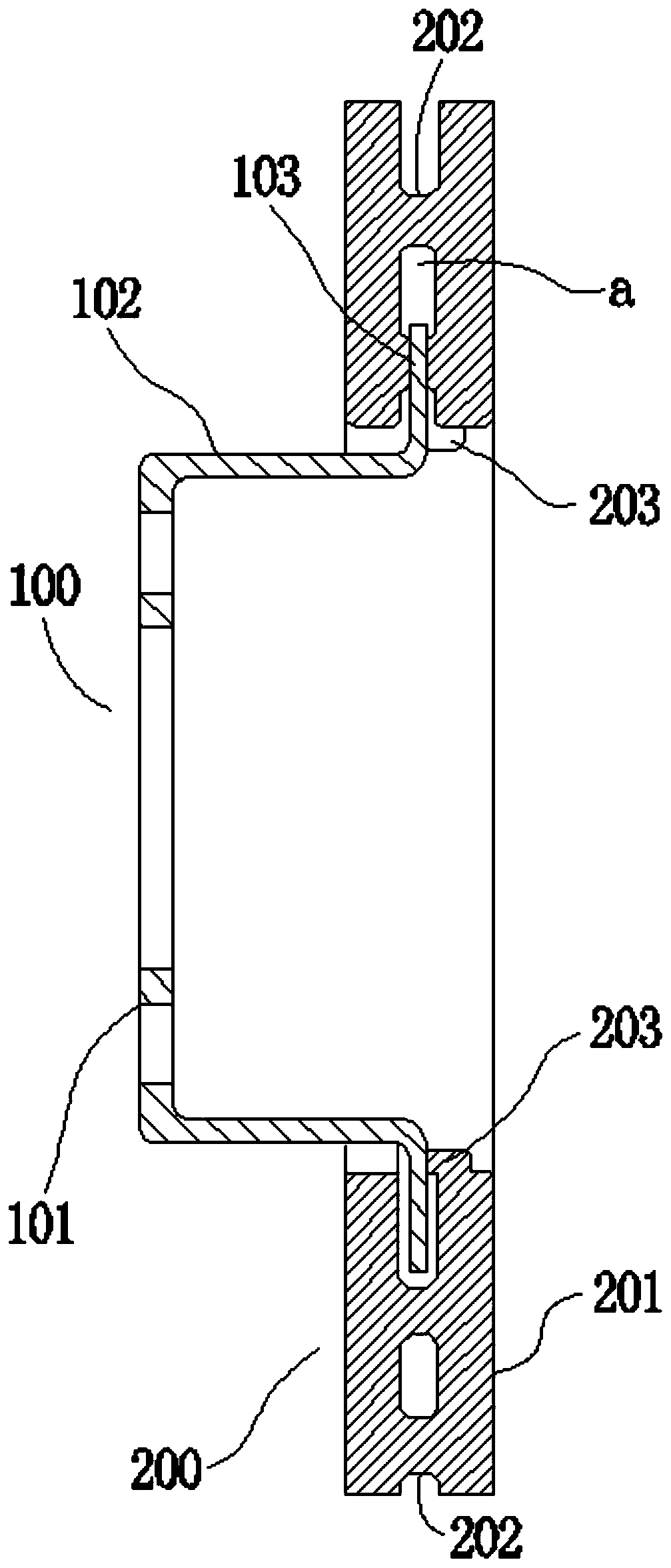

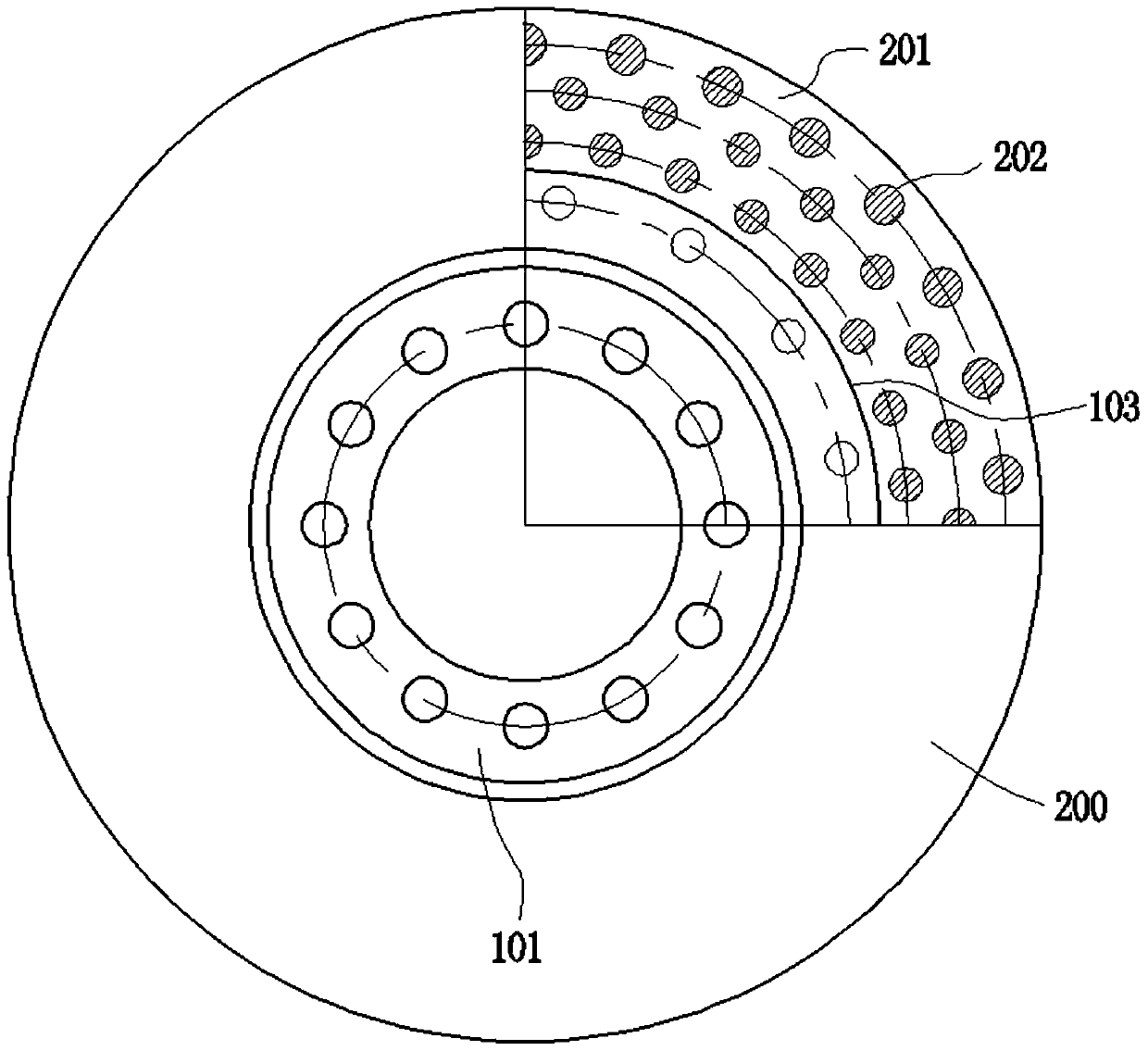

[0037] A bimetal composite brake disc, including a connecting mechanism 100 and a brake disc body 200, the connecting mechanism 100 including an integrally formed flange 101, a connecting body 102 and a composite body 103;

[0038] The connecting body 102 connects the flange 101 and the composite body 103, the connecting body 102 is in a circular tubular structure, one end is provided with an integrally formed flange 101 for connection, and the other end is provided with an integrally formed composite body 103. The composite body 103 is in the shape of a ring, and the composite body 103 has an inner ring edge connected to the connecting body 102;

[0039] The brake disc body 200 has a ring-shaped structure, including two brake disc surfaces 201, the surfaces of the two brake disc surfaces 201 are parallel, and are connected by a number of evenly crossed columns 202, so that the two brake disc surfaces 201 The disk surfaces 201 are connected as one, so that an air channel a is ...

Embodiment 2

[0054] Based on the basis of Embodiment 1, the chemical composition of the high-carbon gray cast iron is adjusted. The brake disc body 200 is made of high-carbon gray cast iron, and the chemical composition of the high-carbon gray cast iron is calculated as:

[0055]C: 3.40-3.90, Si: 1.50-2.10, Mn: 0.50-1.10, P: ≤0.10, S: ≤0.12, Cr: 0.20-0.60, Cu: 0.30-0.60%, and the rest is Fe.

Embodiment 3

[0057] Based on the basis of Embodiment 1, the chemical composition of the high-carbon gray cast iron is adjusted. The brake disc body 200 is made of high-carbon gray cast iron, and the chemical composition of the high-carbon gray cast iron is calculated as:

[0058] C: 3.40-3.90, Si: 1.50-2.10, Mn: 0.50-1.10, P: ≤0.10, S: ≤0.12, Cr: 0.20-0.60, Mo: 0.20-0.50%, and the rest is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com