A liquid ammonia leakage monitoring method and monitoring system

A technology of liquid ammonia and variance, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve problems such as liquid ammonia leakage, and achieve the effect of avoiding false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

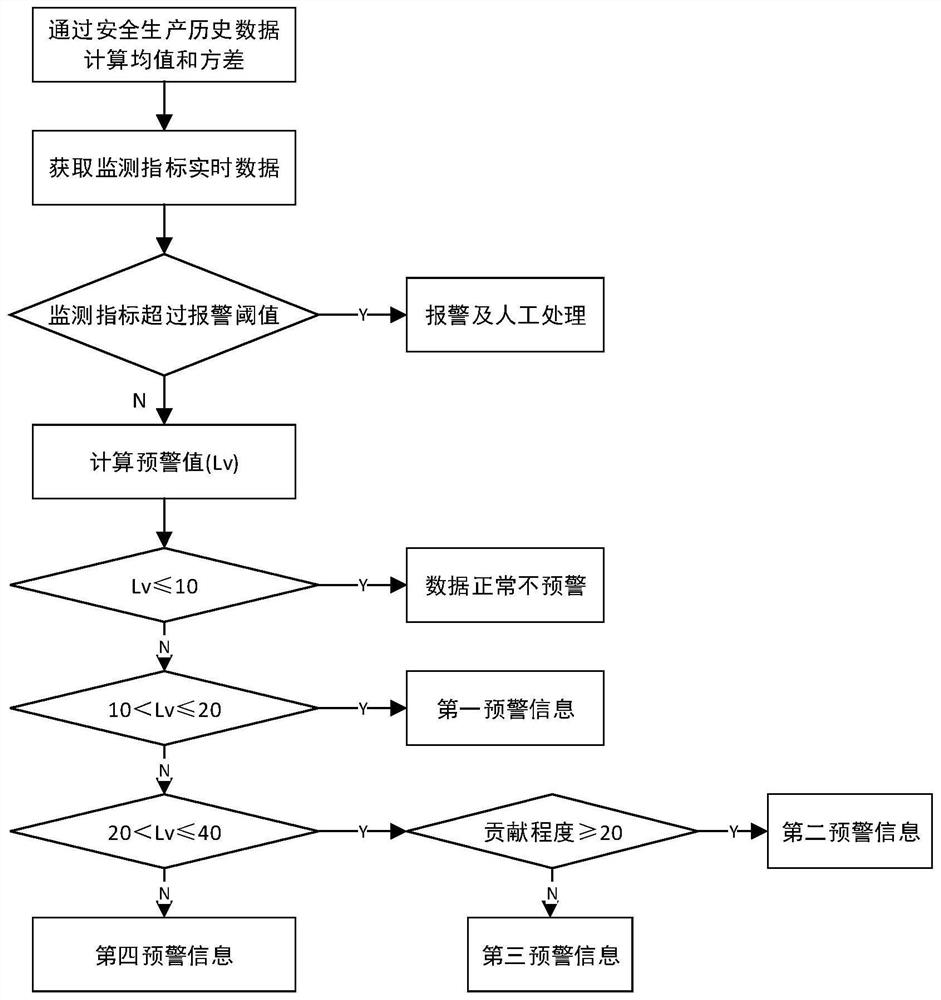

[0041] This embodiment provides a liquid ammonia leakage monitoring method, such as figure 1 As shown, it includes the following steps:

[0042] S1. During the production process of liquid ammonia, obtain the safety production history data of several monitoring indicators in a certain period (such as at least one month), and the safety production history data is the data that does not exceed the preset value and generates an alarm signal;

[0043] And assuming that the safety production history data of each monitoring index in this period of time all belong to normal distribution, calculate the indicator mean value and index variance of the safety production history data of each monitoring index in this period of time; Including: one or more of ammonia concentration, pressure, liquid level, etc. Correspondingly, the indicator average value and indicator variance of the safety production historical data of monitoring indicators within this period include the ammonia gas concent...

Embodiment 2

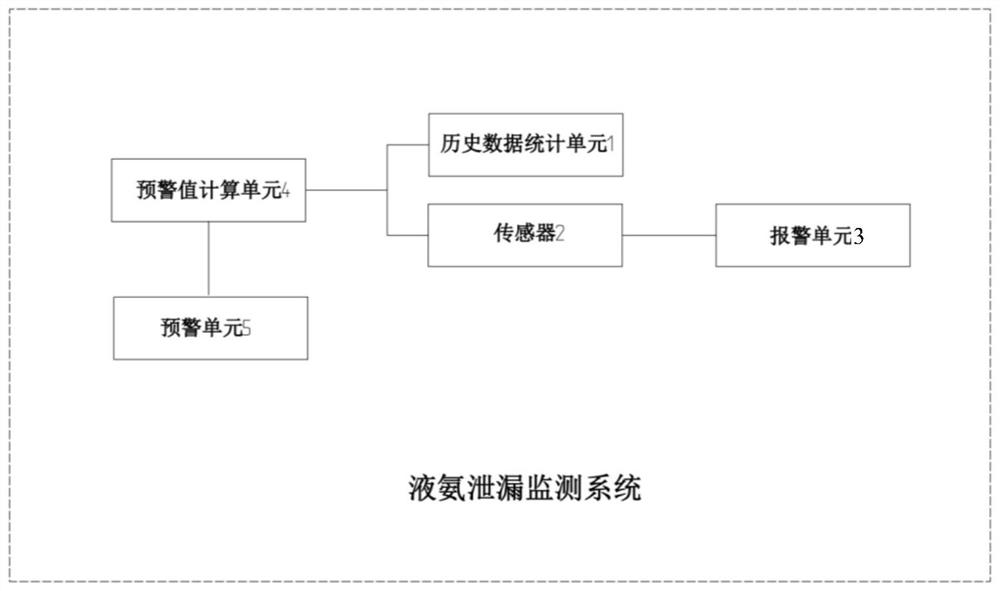

[0062] This embodiment provides a liquid ammonia leakage monitoring system for implementing the monitoring method described in Embodiment 1, such as figure 2 shown, which includes:

[0063] Historical data statistical unit 1, which is used to obtain the safety production history data of several monitoring indicators in a certain period (such as at least one month); and calculate the index average value of the safety production history data of each monitoring indicator in this period of time and index variance;

[0064] Sensor 2, which is used to obtain real-time data of at least one monitoring indicator (preferably several, such as 3);

[0065] An alarm unit 3, which is connected to the sensor 2, is used to directly generate an alarm signal when the real-time data of at least one monitoring indicator exceeds a corresponding alarm threshold;

[0066] Early warning value calculation unit 4, which is connected to the sensor 2 and the historical data statistics unit 1, is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com