Slurry circulating pump optimization method and system based on data driving

A slurry circulation pump, data-driven technology, applied in the field of desulfurization, can solve problems such as single index, only guiding, ignoring index correlation, etc., to achieve the effect of improving the degree of automation, reliable design principles, and reducing the degree of participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

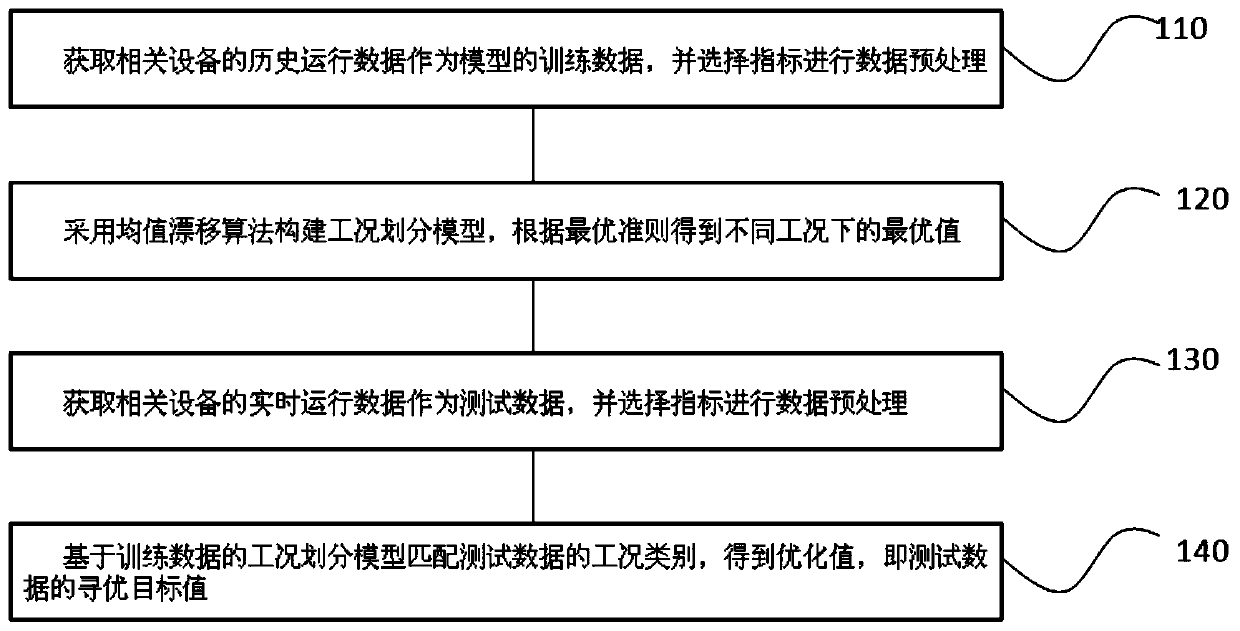

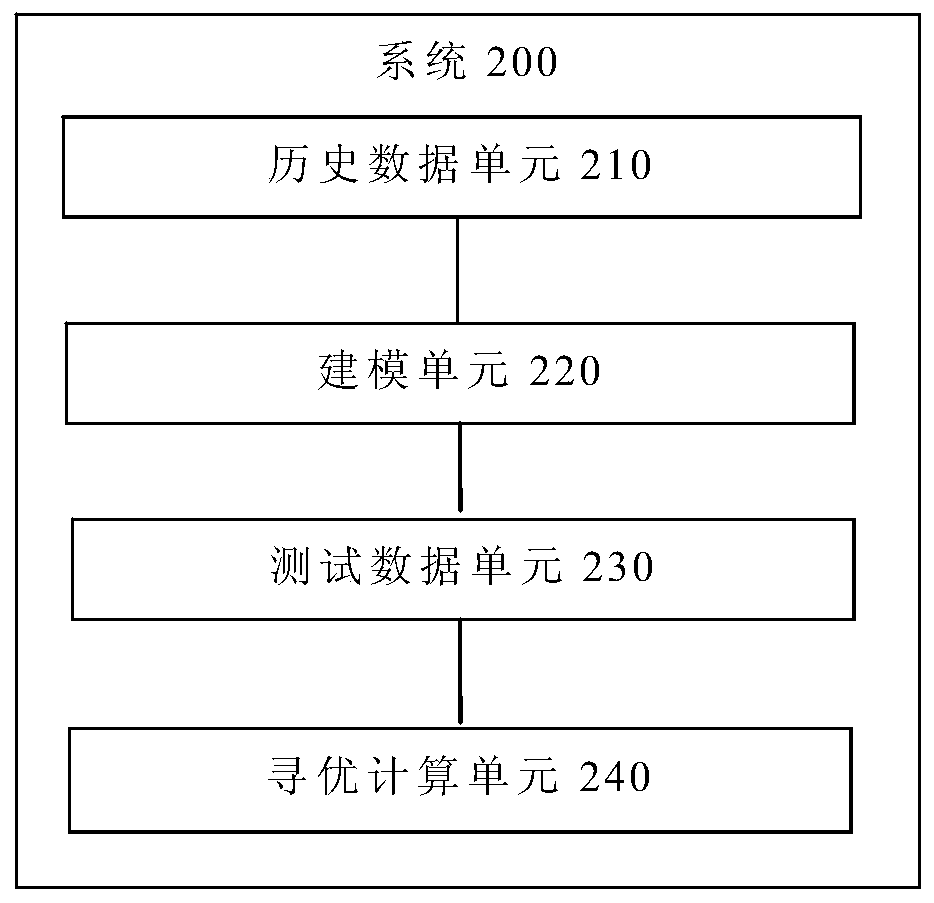

[0124] Specifically, the data-driven optimization method for slurry circulation pump includes:

[0125] This embodiment takes the slurry circulating pump of a unit of a thermal power plant as an object. The slurry circulating pump is an important device for desulfurization operation in the thermal power generation system. The detailed description of this embodiment will further illustrate the implementation process of the present invention.

[0126] The implementation steps of the optimization of the slurry circulating pump of a power plant in the embodiment of the present invention are as follows:

[0127] S1. Obtain historical operating data of related equipment as training data of the model, and select indicators for data preprocessing.

[0128] S1.1. Obtain the training data of the slurry circulating pump

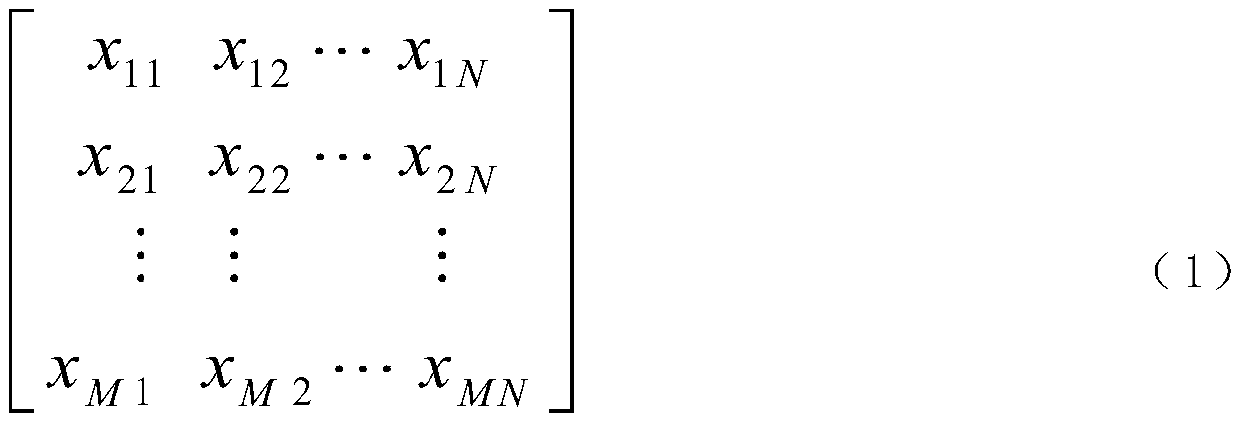

[0129] There are a total of 21 main measurement points related to the slurry circulating pump, including unit load, slurry supply flow, inlet sulfur dioxide conversion concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com