A rock material processing device based on civil engineering

A rock material and processing device technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of low gluing efficiency, tedious and time-consuming repetitive actions, inconvenient use, etc., and achieve simple and convenient operation and high efficiency. Efficiency of squeegee operation and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

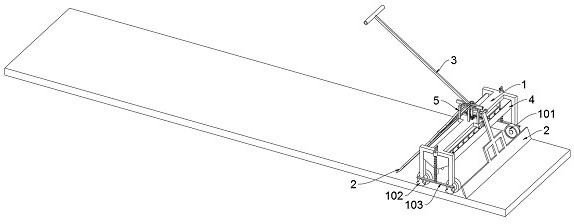

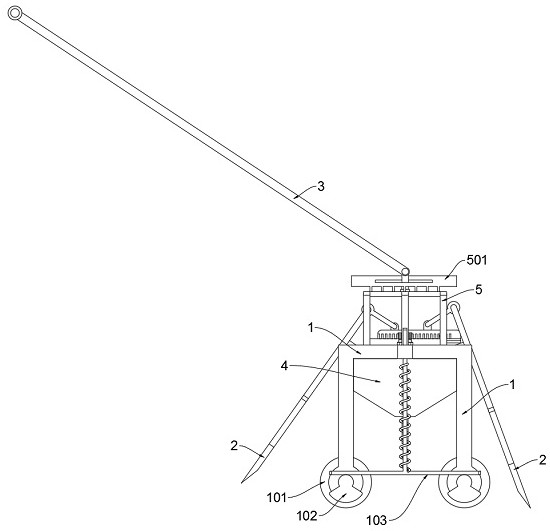

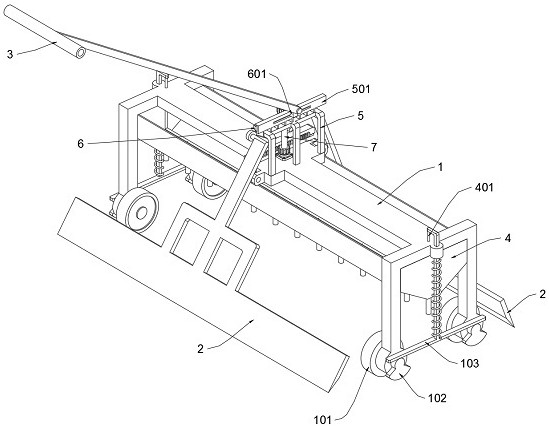

[0030] see Figure 1 to Figure 9 , an embodiment provided by the present invention: a rock material processing device based on civil engineering, comprising a main body support 1, a scraper 2 and a convex rack 6, the main body support 1 includes a rubber roller 101, a sector cam 102, T-shaped push rod 103 and track groove 104, the main body bracket 1 is formed by two supporting frames on the left and right and the cross-bracing connecting plates welded on the top of the two supporting frames, wherein the four supporting frames on the left and right are vertically supporting the side bars A rubber roller 101 is installed at each end to rotate, and a fan-shaped cam 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com