Coating and curing production line

A coating and production line technology, applied in the direction of coating, device for coating liquid on surface, surface pretreatment, etc., can solve problems such as operator's health injury, equipment injury, inability to complete, etc., to achieve modernization of production, The effect of reducing the volatilization of the coating liquid and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

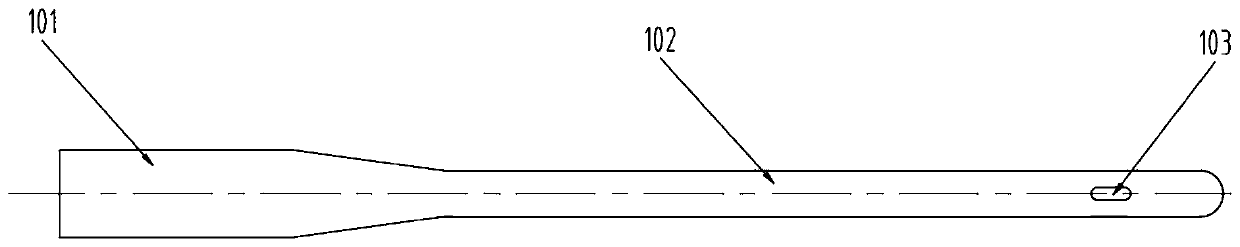

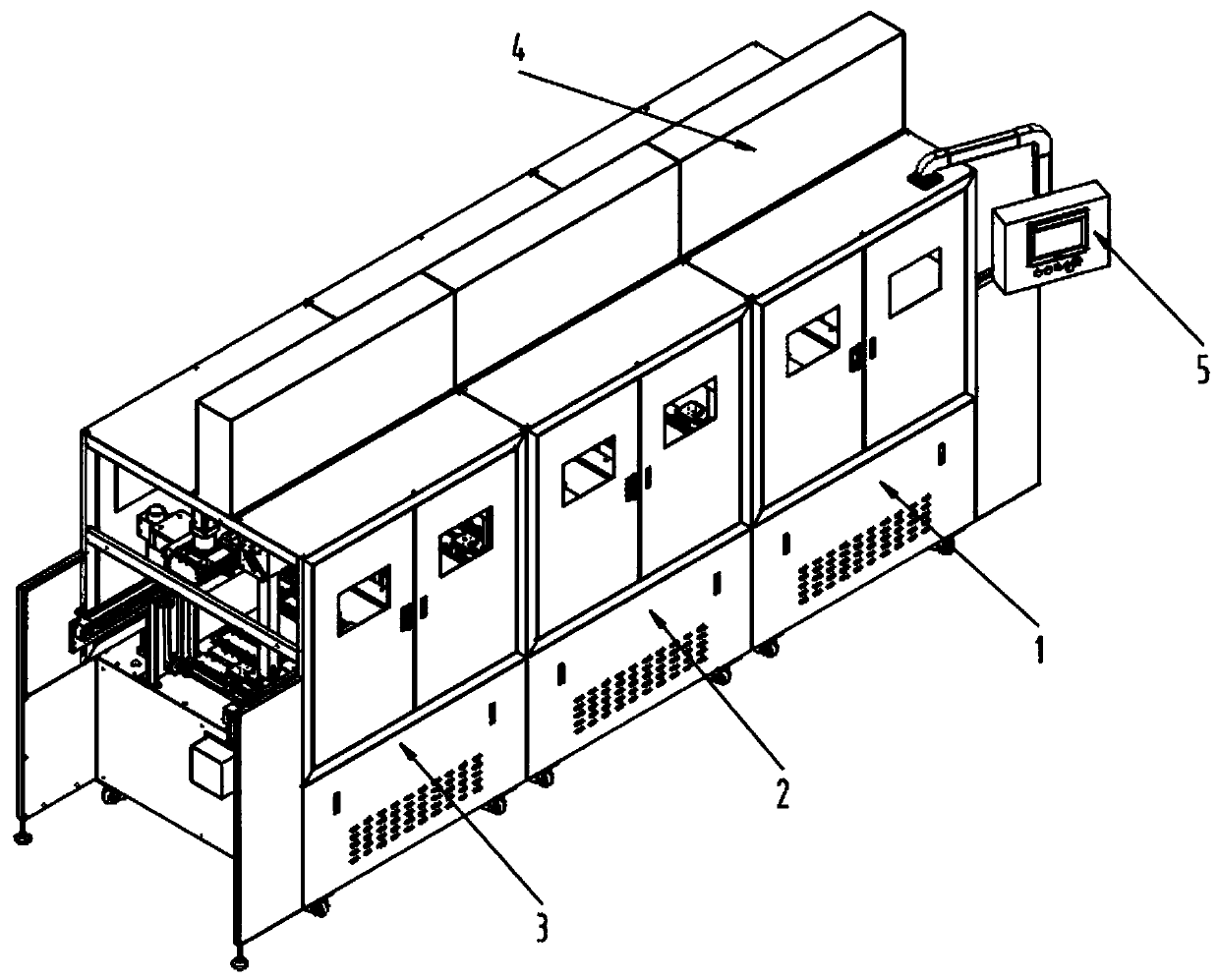

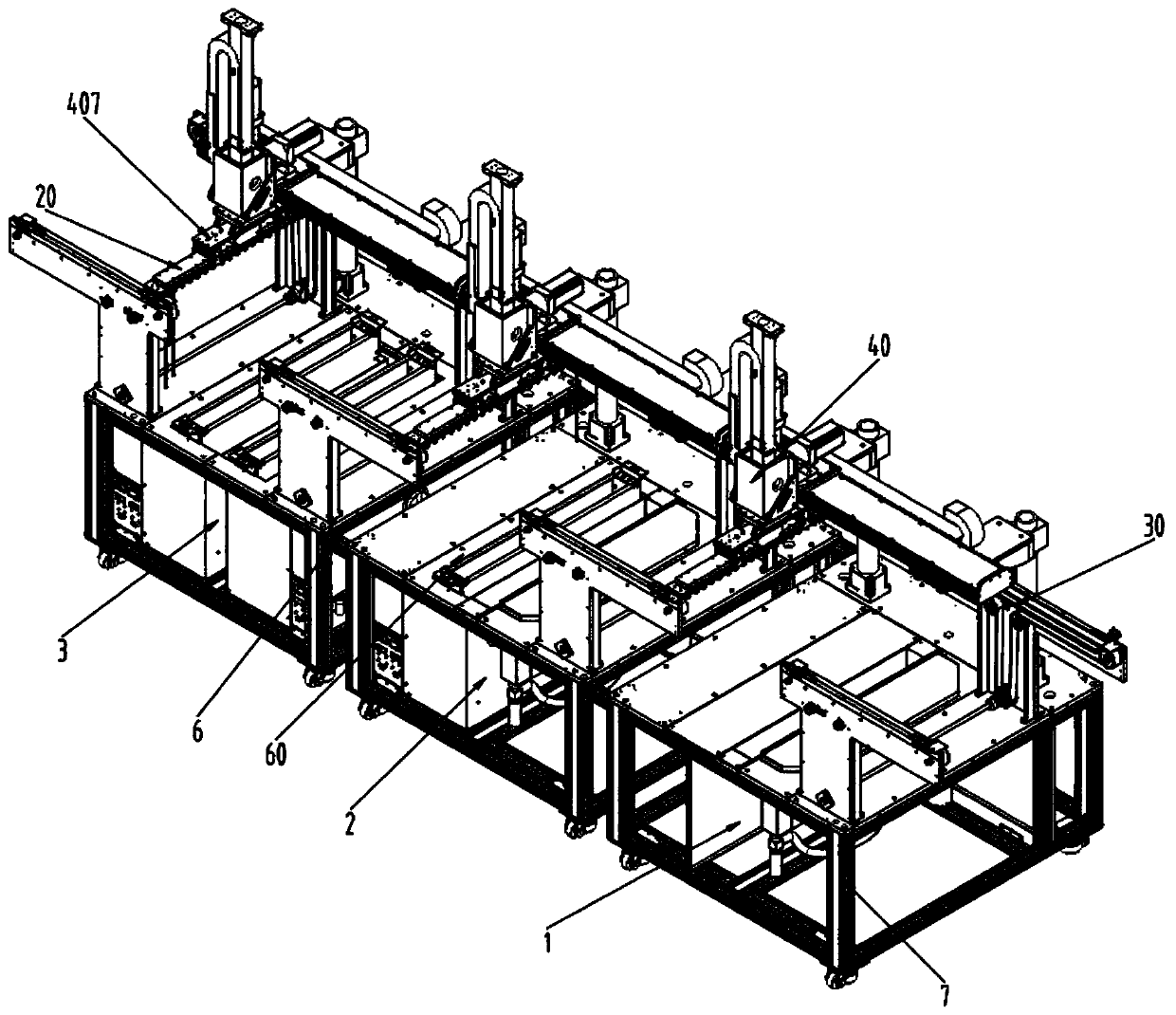

[0092] see Figure 2-23 , figure 2 It is a structural schematic diagram of the complete machine of this embodiment; image 3 It is a schematic diagram of the internal structure of the complete machine of this embodiment; Figure 4 It is a schematic structural diagram of the vehicle in this embodiment; Figure 5 It is a schematic diagram of the internal structure of the vehicle in this embodiment; Image 6 It is a schematic diagram of the structure of the cover plate of the carrier in this embodiment; Figure 7 It is a structural schematic diagram of the vehicle looking up in this embodiment; Figure 8 for Figure 7 The enlarged schematic diagram of part I in the middle; Figure 9 It is a structural schematic diagram of the first part of the whole machine in this embodiment; Figure 10 It is a schematic structural diagram of the second part of the whole machine in this embodiment; Figure 11 It is a schematic structural diagram of the third part of the complete machine i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com