Stamping die good in sealing effect

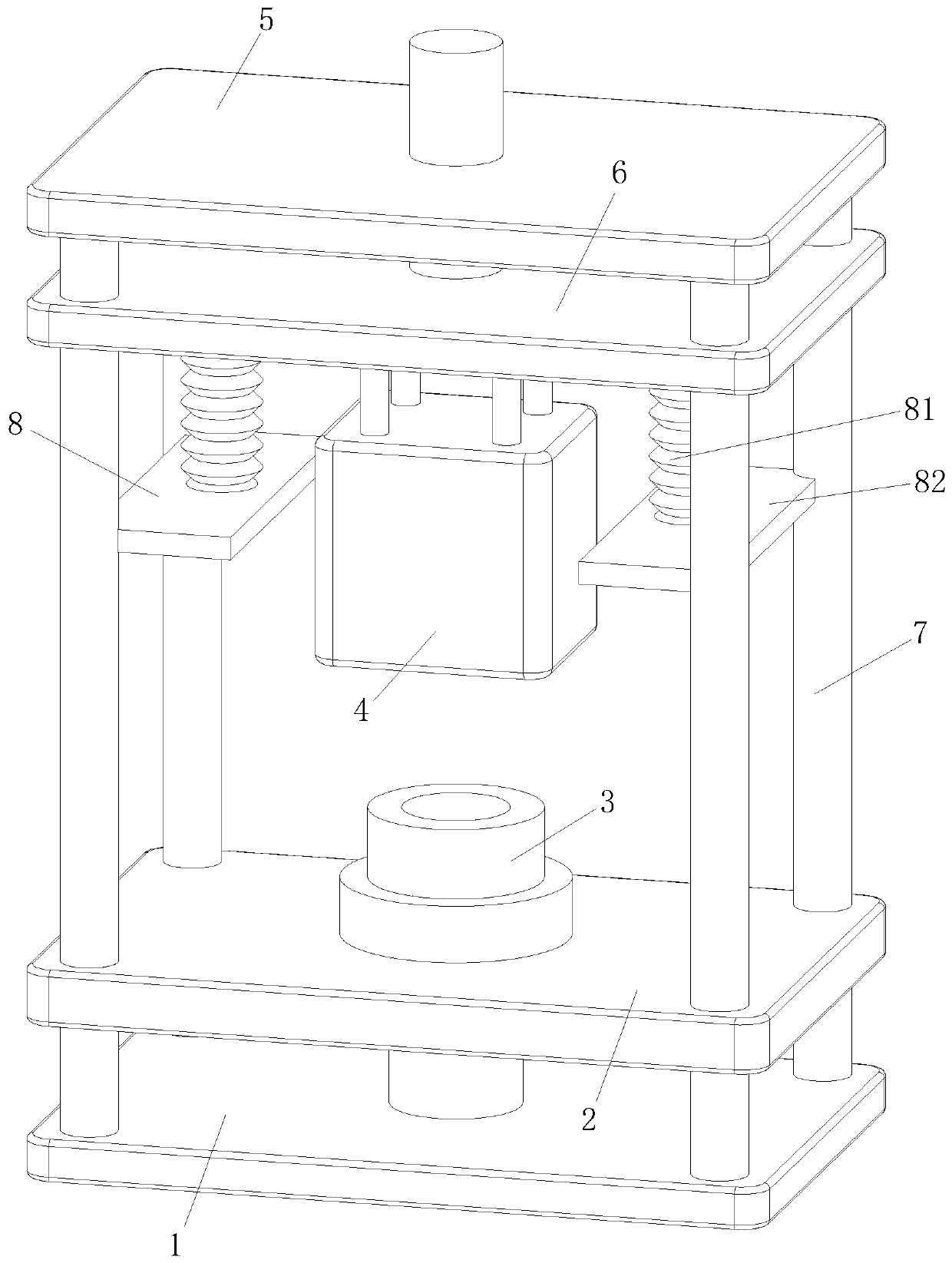

A technology of sealing effect and stamping die, which is applied in the field of stamping dies, can solve the problems of high noise of stamping dies, splashing of billet waste, reducing stamping effect, etc., to achieve the effect of ensuring the overall use effect, enhancing the overall use effect, and strengthening the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

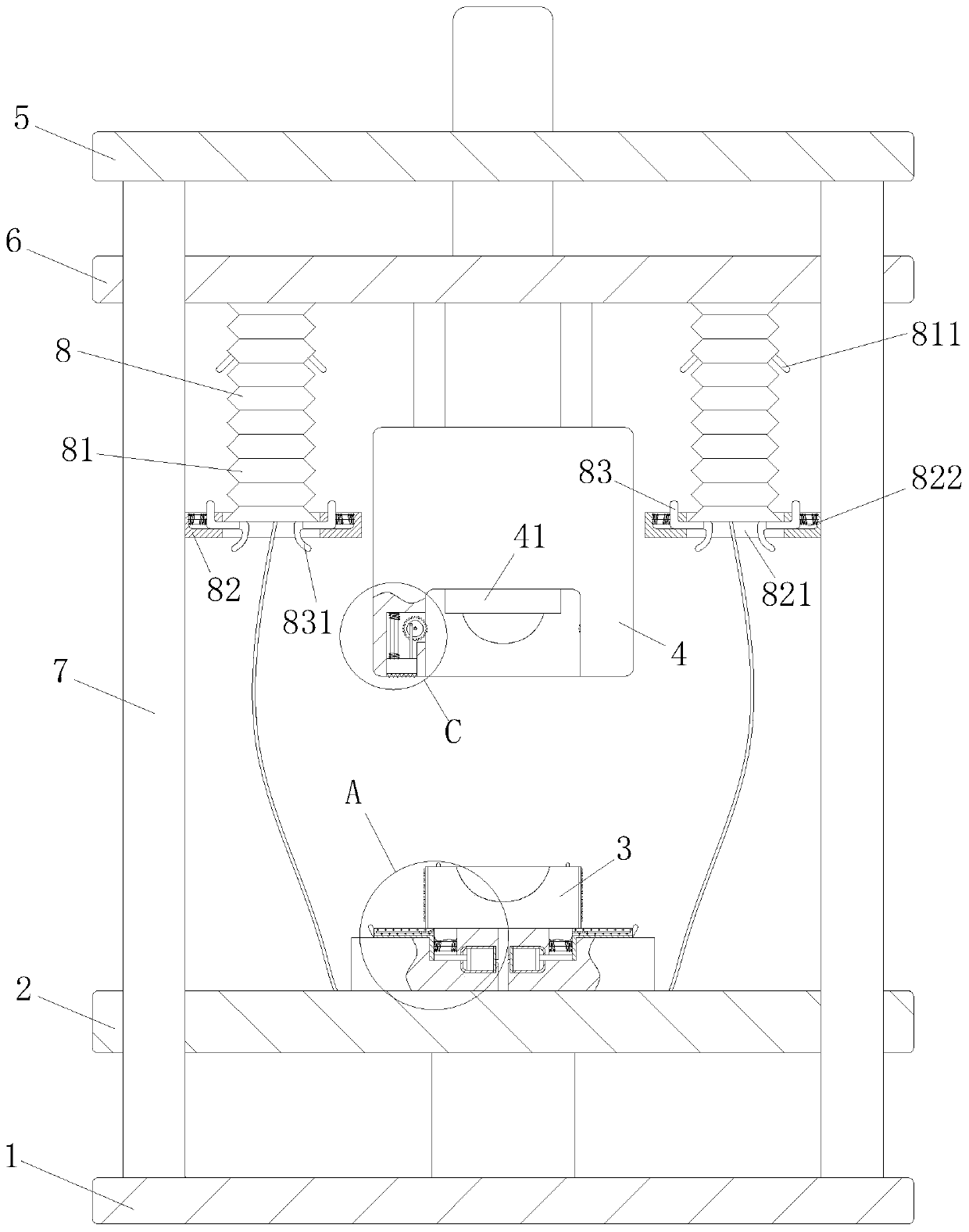

Embodiment approach

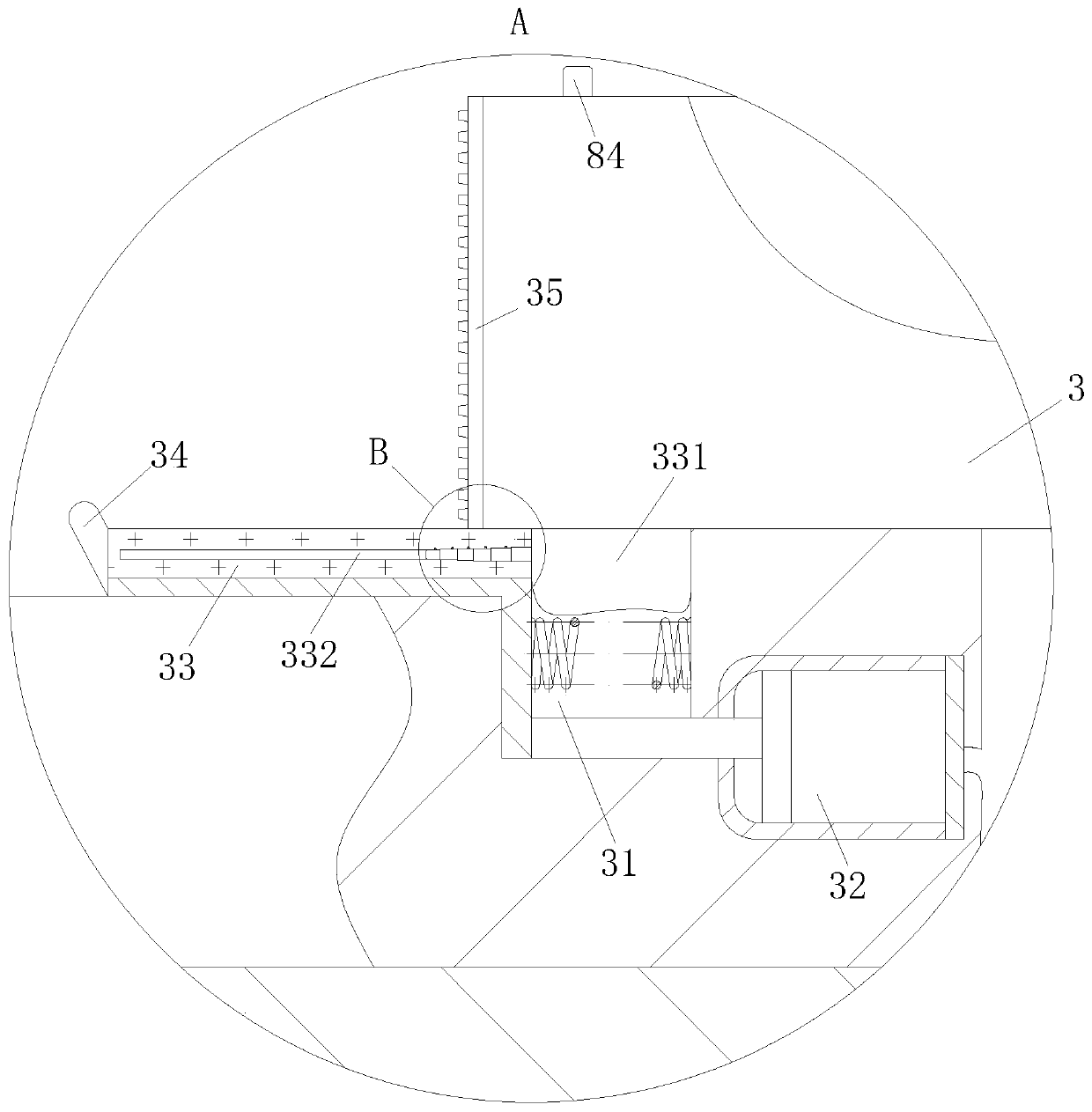

[0023] As an embodiment of the present invention, a No. 2 chute 31 is symmetrically opened in the lower mold 3, and a piston cylinder 32 is provided near the No. 2 chute 31. The piston cylinder 32 is connected to the stacked airbag 81 through a hose Connected; the No. 2 chute 31 is slidingly connected with a rubber backing plate 33 through a spring; the rubber backing plate 33 is in contact with the output end of the piston cylinder 32 near the side wall of the piston cylinder 32, and the rubber backing plate 33 is away from the side of the piston cylinder 32 The wall is provided with a scraper 34; the sealing effect between the upper mold 4 and the lower mold 3 is further strengthened through the cooperation of the piston cylinder 32, the rubber backing plate 33 and the scraper 34; during work, during the downward movement of the second top plate 6 , the top of the stacked airbag 81 moves down thereupon, but since the L-shaped stopper 83 blocks the through hole 821, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com