Packaging box riveting equipment

A packaging box and riveting technology, which is applied in the field of packaging box riveting equipment, can solve problems such as left and right sliding deviation, packaging box damage, riveting position deviation, etc., and achieve the effect of improving stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

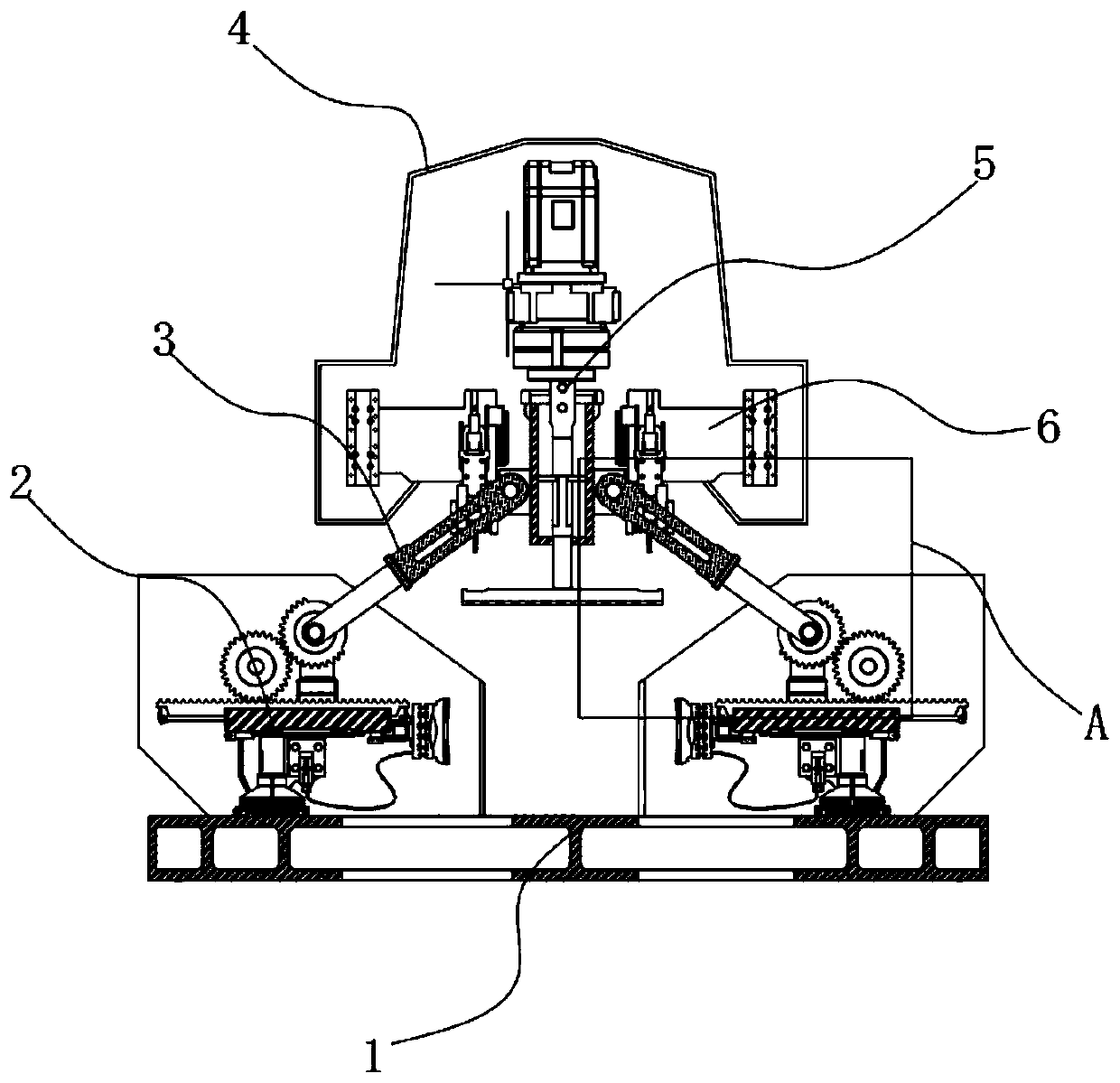

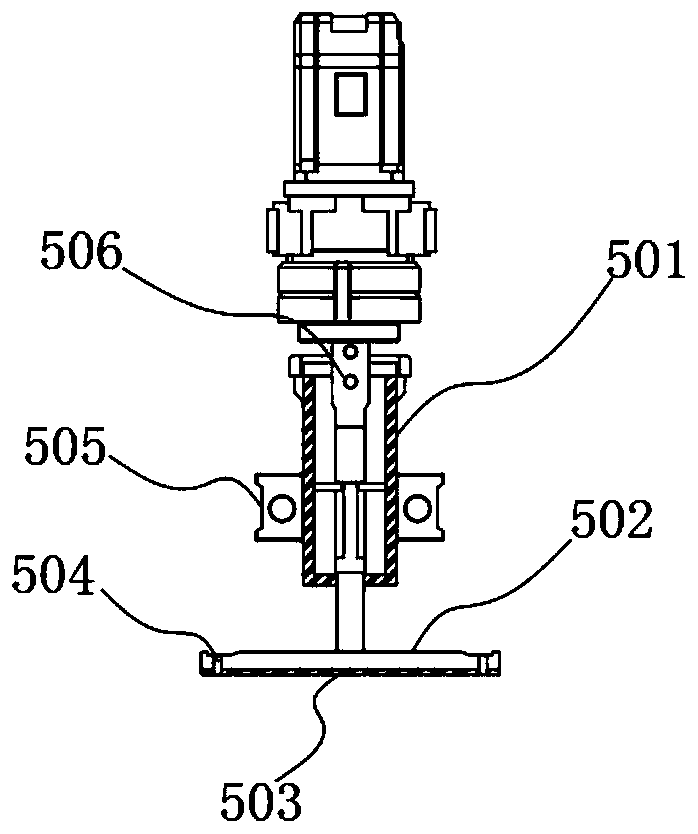

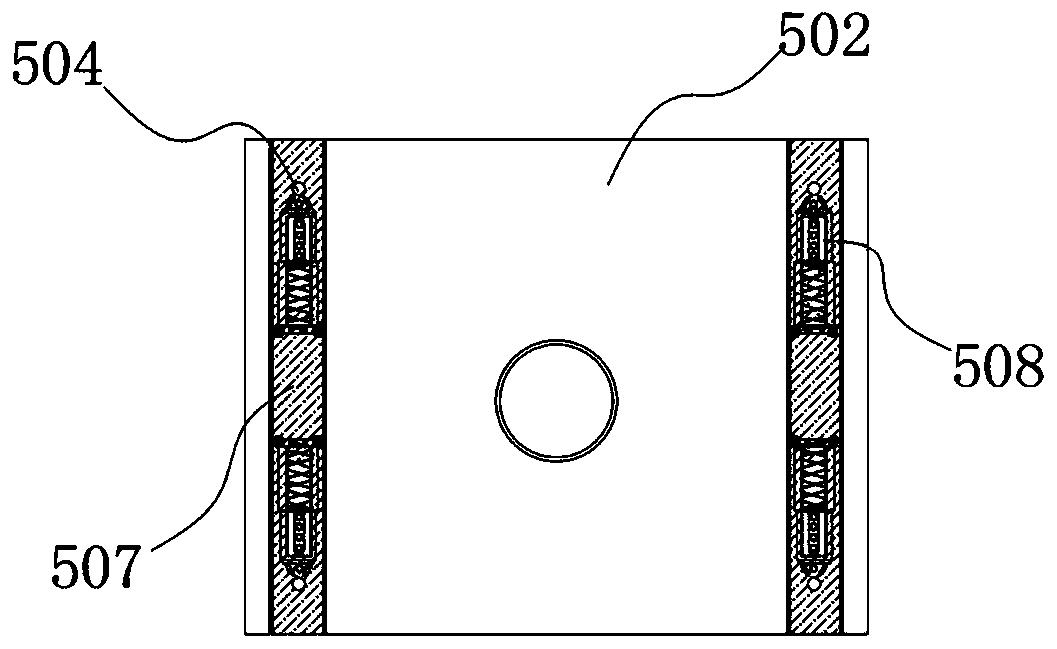

[0023] refer to figure 1 , the present invention provides a technical solution: a packing box riveting equipment, which includes a working table 1, a vertical pressure control component 5, a rivet assembly component 6, a horizontal fastening component 2, a transmission component 3 and a body shell 4, which It is characterized in that two sets of transverse fastening assemblies 2 are arranged symmetrically on both sides of the upper end surface of the worktable 1, and the two sets of transverse fastening assemblies 2 press and fix the left and right side plates of the packing box, so that the The rivet assembly assembly 6 will not produce relative offset when the two side panels of the packaging box are riveted to the packaging box. The upper end of the work table 1 is also provided with a vertical pressure control assembly 5, and the vertical pressure control assembly 5 is arranged in two groups. Between the horizontal fastening components 2, and through the transmission compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com