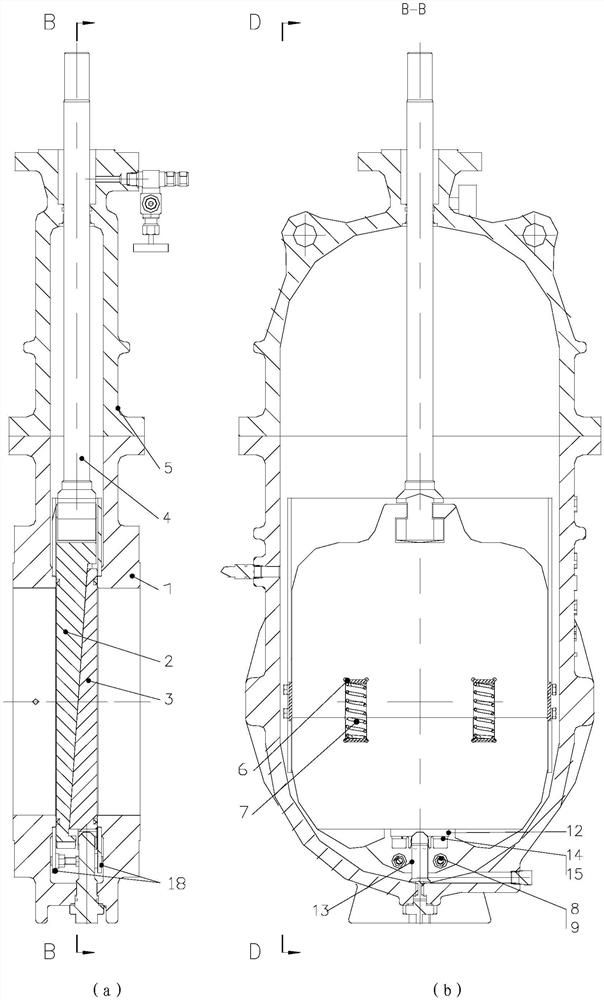

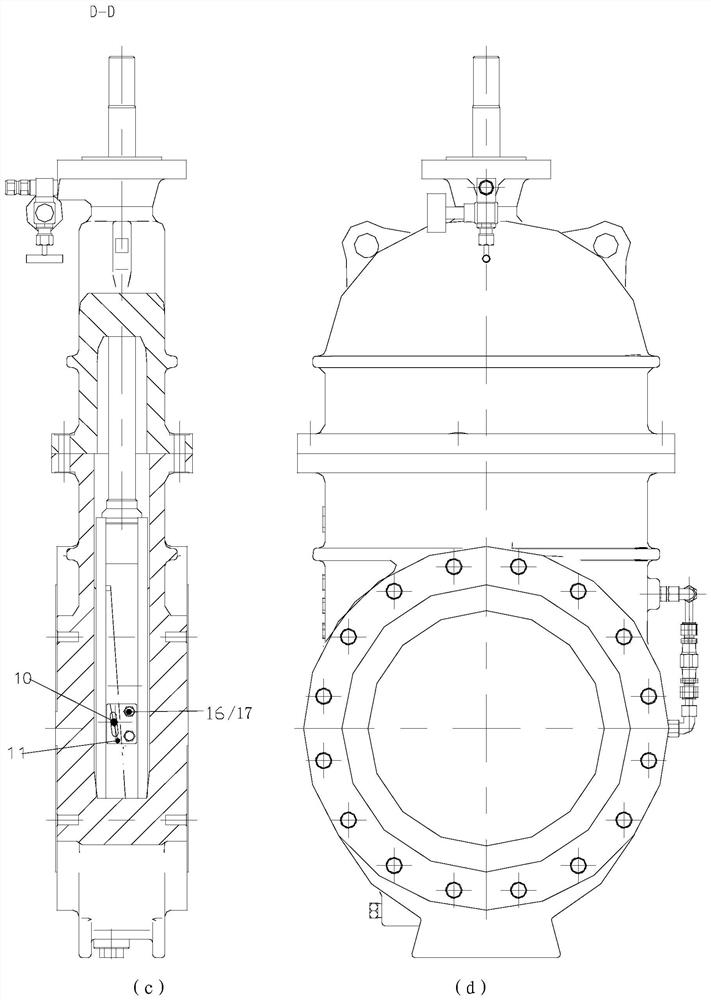

Flat gate valve

A technology for flat gate valves and gates, applied in valve devices, sliding valves, mechanical equipment, etc., can solve problems such as scratched sealing surfaces, valve leakage, etc., and achieve the effects of reducing friction, increasing service life, and reducing operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

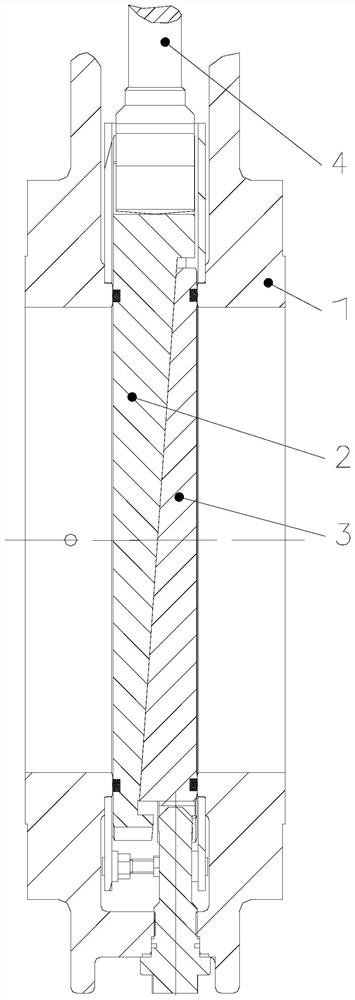

Method used

Image

Examples

Embodiment Construction

[0026] Unless otherwise specified, the terms herein are understood according to the understanding of one of ordinary skill in the relevant art.

[0027] The direction or orientation terms such as axial, relative, bottom, bottom, etc. described herein are consistent with the corresponding directions or orientations in the drawings in the description. It should be noted that the directions or orientations in the drawings in the description are an example of the present invention. Equivalent rotations and exchanges made by those skilled in the art on the basis of the contents disclosed in the present invention are all within the protection scope of the present invention.

[0028] The combined thickness of the combined valve plate is the sum of the thickness between the board surface A and the board surface B of the power gate and the thickness between the board surface C and the board surface D of the auxiliary gate. The axial direction gradually becomes smaller, and the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com