Multi-directional top-cover grounding grid spacer assembly and construction method thereof

A construction method and grounding grid technology, applied in the field of power systems, can solve problems such as cumbersome operations and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

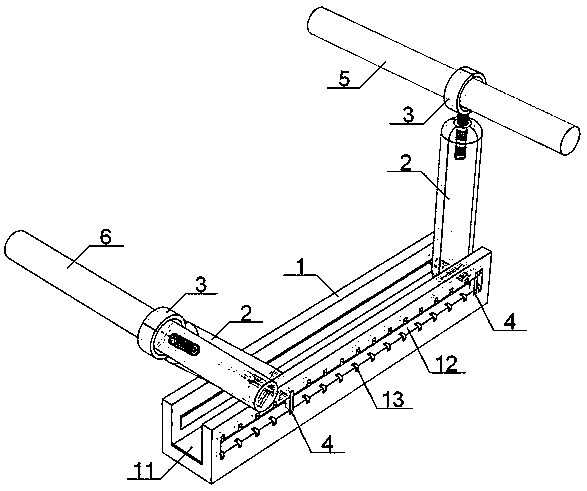

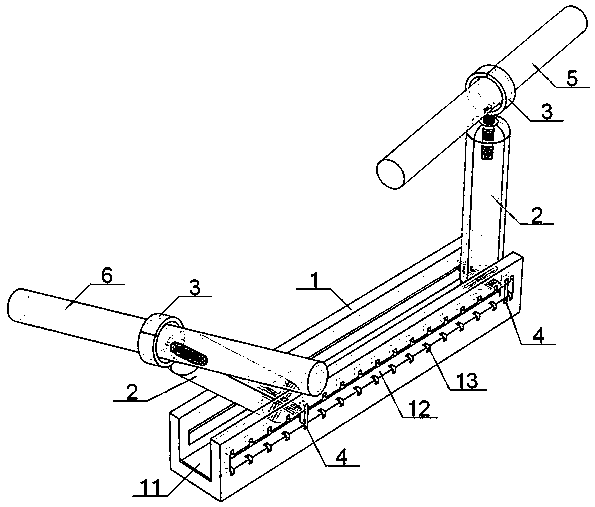

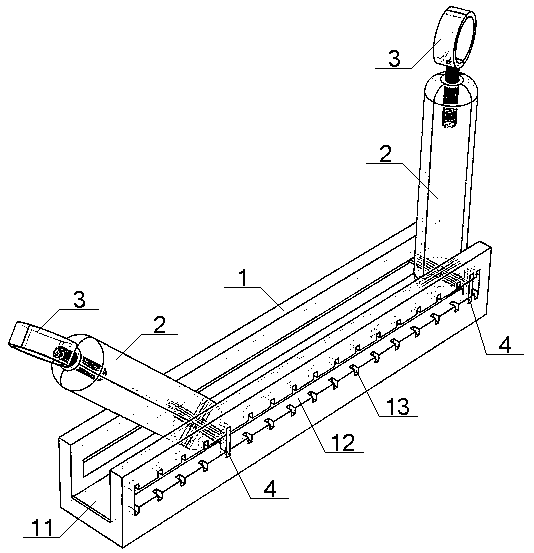

[0050] see image 3 , a multi-directional top cover type grounding grid spacer assembly, including a bottom groove 1, a spacer 2, a spacer top cover 3 and a plate-type latch 4; the bottom groove 1, spacer 2, spacer top cover 3 and plate The manufacturing material of type latch 4 is epoxy resin, nylon or polytetrafluoroethylene.

[0051] see Figure 4 , the bottom groove 1 is a straight structure, the middle part of the bottom groove 1 is provided with a first groove 11 that runs through the two ends of the bottom groove 1, and the side of the bottom groove 1 is provided with a second groove that runs through the two sides of the bottom groove 1 12. The second groove 12 and the first groove 11 are arranged in a cross-shaped intersection, and a plurality of third grooves 13 are arranged on one side of the bottom groove 1 along its horizontal direction, and the third groove 13 and the second groove 12 are arranged in a cross shape; the overall size of the bottom groove 1 is 250...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com