Sealed pressure feed type horizontal directional drilling engineering geological survey continuous coring device

A technology of horizontal orientation and engineering geology, applied in the directions of directional drilling, undisturbed core extraction devices, drilling equipment, etc., it can solve the problems of difficult implementation, inability to take cores, and formation information cannot meet the needs of engineering design, etc. Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

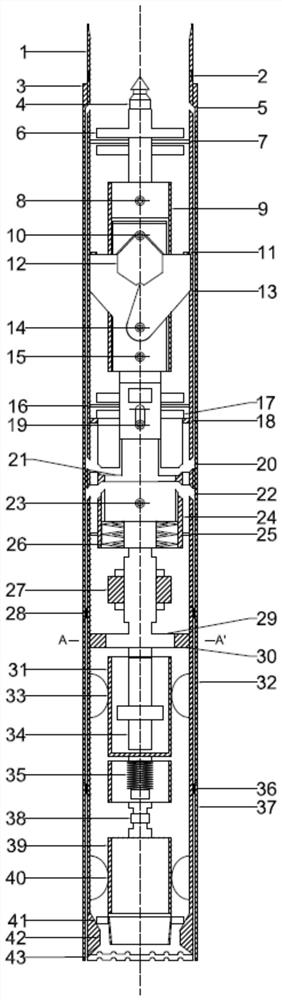

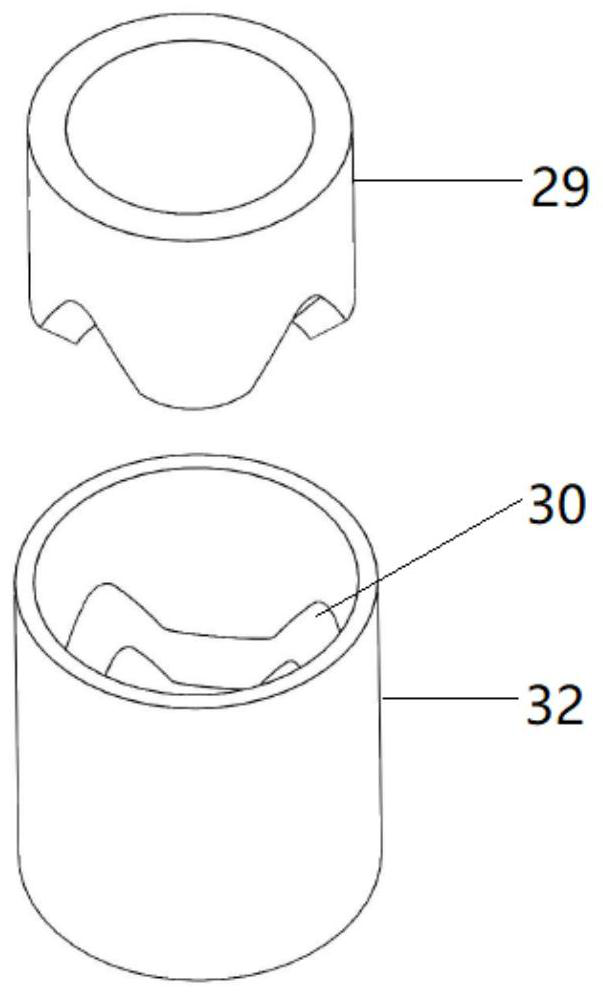

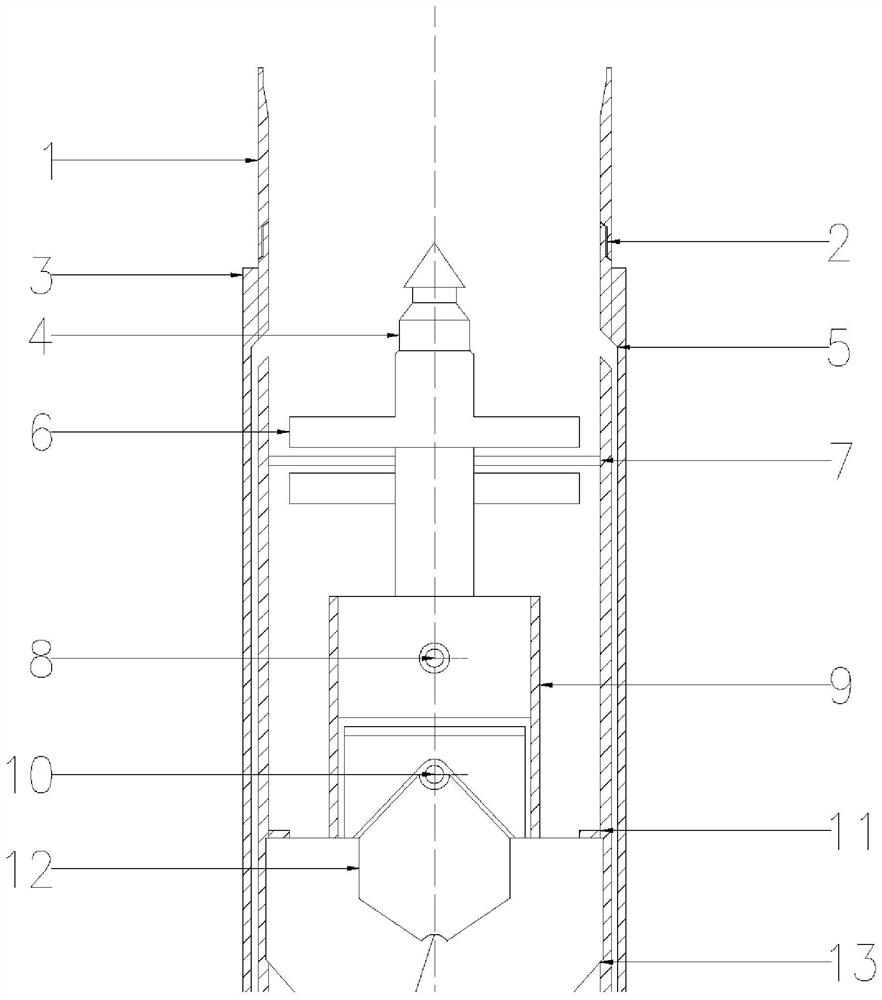

[0026] Such as figure 1 and 2 As shown, the sealed pressure-feeding horizontal directional drilling engineering geological survey continuous coring device of the embodiment of the present invention includes an outer pipe assembly and an inner pipe assembly used in conjunction with the outer pipe assembly, and the outer pipe assembly includes A single-wall drill rod 1 and a double-wall drill rod, the single-wall drill rod is located on the upper part of the double-wall drill rod, and the inner wall of the double-wall drill rod is sequentially provided with a bullet stopper 11 and a bullet stopper 11 from top to bottom. Chamber 13, suspension seat ring 18, probe chamber positioning inner card 29, probe chamber positioning outer card 30, centering rings 33 and 40, spring seat 42 and drill bit 43;

[0027] The inner pipe assembly is located inside the drill pipe, and incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com