Phosphate laser glass component loading case

A laser glass, phosphate technology, applied in the direction of packaging objects, internal accessories, transportation and packaging under special gas conditions, can solve the problems of scratches, secondary pollution on the surface of glass components, and heavy metal box weight. The effect of reducing the contact area, avoiding secondary pollution and scratches, and good sealing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

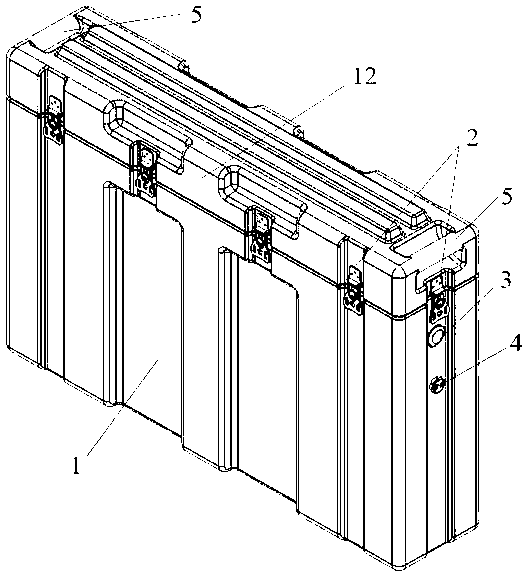

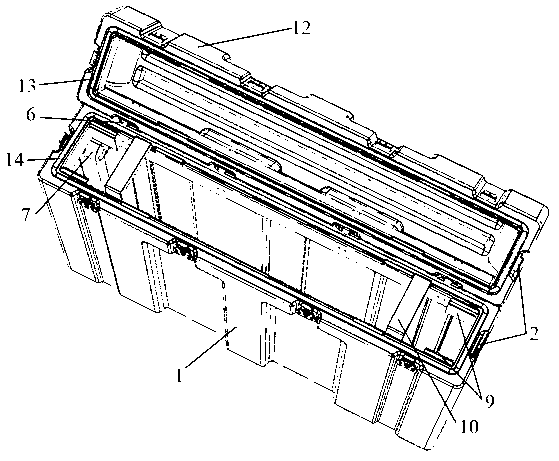

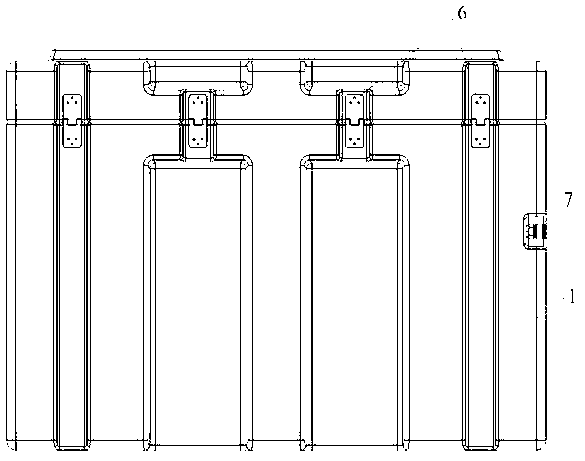

[0024] see first Figure 1 to Figure 5 As shown, it can be seen from the figure that the shipping box of the phosphate laser glass element of the present invention includes a box body 1, a buckle 2, a hinge 6, a box cover 12, a box cover sealing groove 13 (with a silicone sealing ring inside), a box body The sealing strip 14, through the hinge 6 and the hasp 2, seals the sealing groove 13 of the box cover (with a silicone rubber sealing ring inside) and the sealing strip 14 of the box tightly, so that the box cover 12 It forms a sealing body with the box body 1, and the box body sealing strip 14 of the box body 1 adopts an integrated design, which can play a position-limiting role with the box cover sealing groove 13, and the box body One end of the box 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com