Aluminum alloy hub tool positioning fixture

A positioning technology for aluminum alloy wheels and tooling, applied to positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as inability to ensure processing accuracy and high labor intensity, and achieve the effects of simple operation, guaranteed processing accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

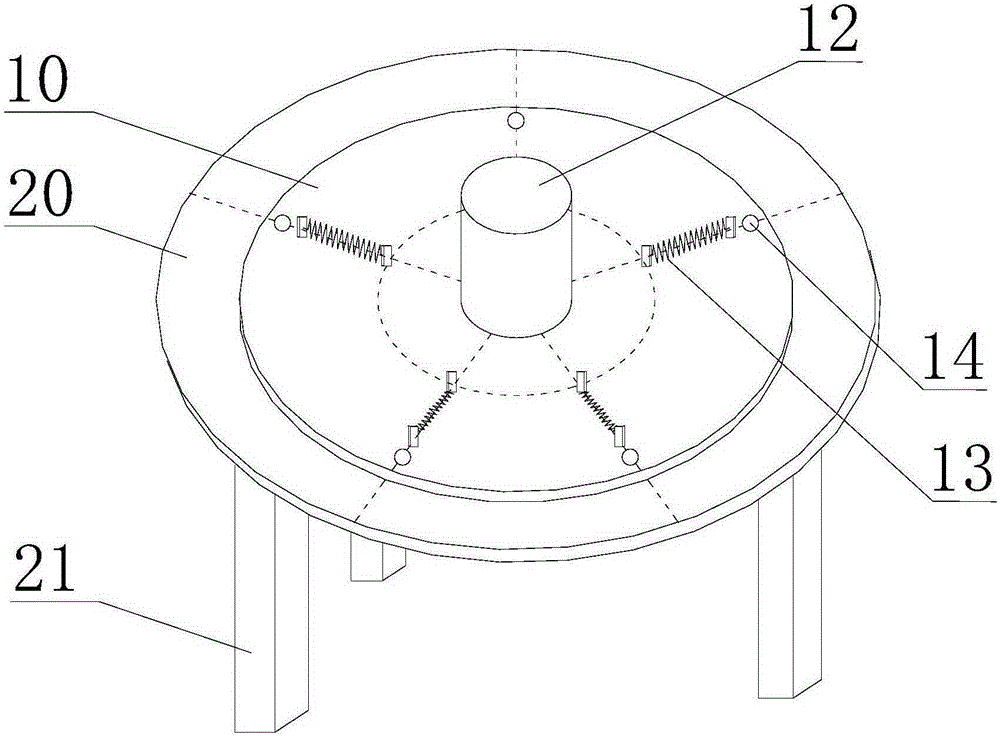

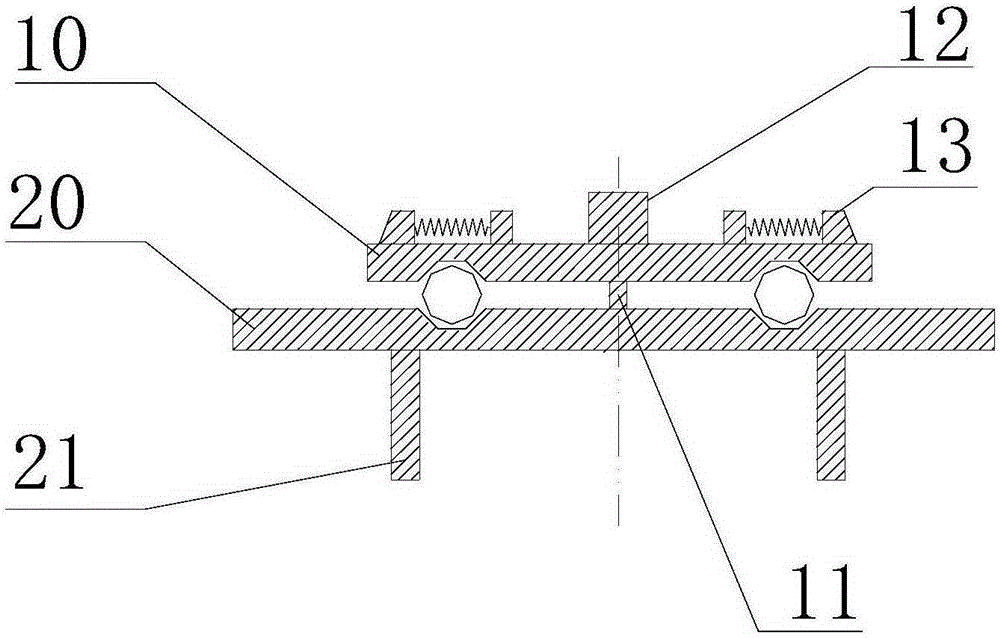

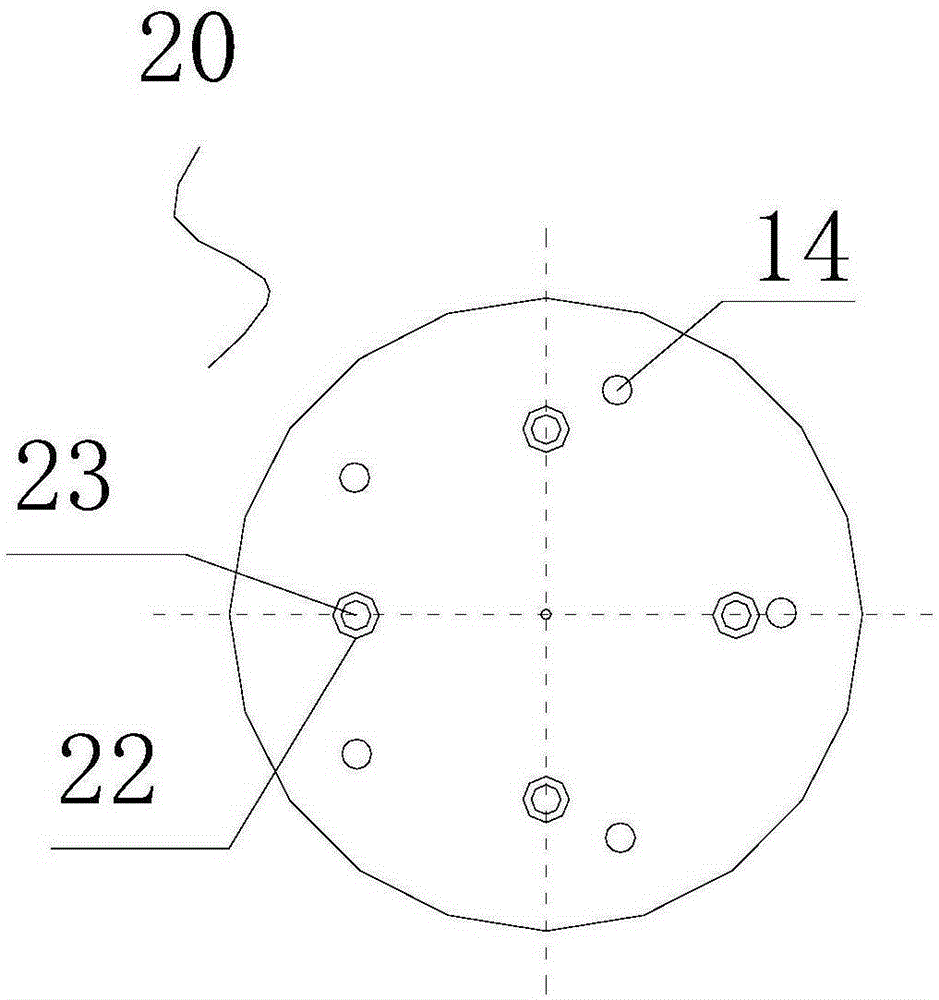

[0015] Please also see Figure 1 to Figure 4 , figure 1 It is a perspective view of the aluminum alloy wheel tooling positioning fixture of the present invention, figure 2 It is a side view of the aluminum alloy wheel tooling positioning fixture of the present invention, image 3 yes figure 1 Schematic diagram of the top surface of the mid-chassis, Figure 4 yes figure 1 Schematic diagram of the bottom surface of the middle tray. The aluminum alloy wheel tooling positioning fixture comprises a pie-shaped tray 10 and a chassis 20 stacked up and down, the diameter of the chassis 20 is larger than the diameter of the tray 10, and the tray 10 and the chassis 20 are connected by a bearing 11 to make the tray 10 It can rotate relative to the chassis 20, and the chassis 20 is fixedly provided with supporting legs 21.

[0016] Four recessed hemispherical holes 22 are symmetrically arranged on the top surface of the chassis 20, and the holes 22 are located on the quadrants of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com