Permanent magnet motor rotor processing technology and rotor assembly

A processing technology, permanent magnet motor technology, applied in the direction of electromechanical devices, manufacturing motor generators, magnetic circuit rotating parts, etc., can solve the problems of high cost, complicated process flow, and many steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

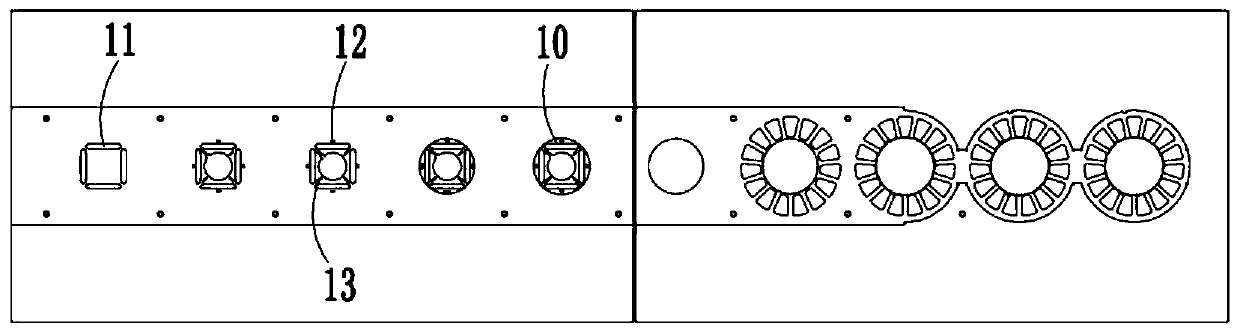

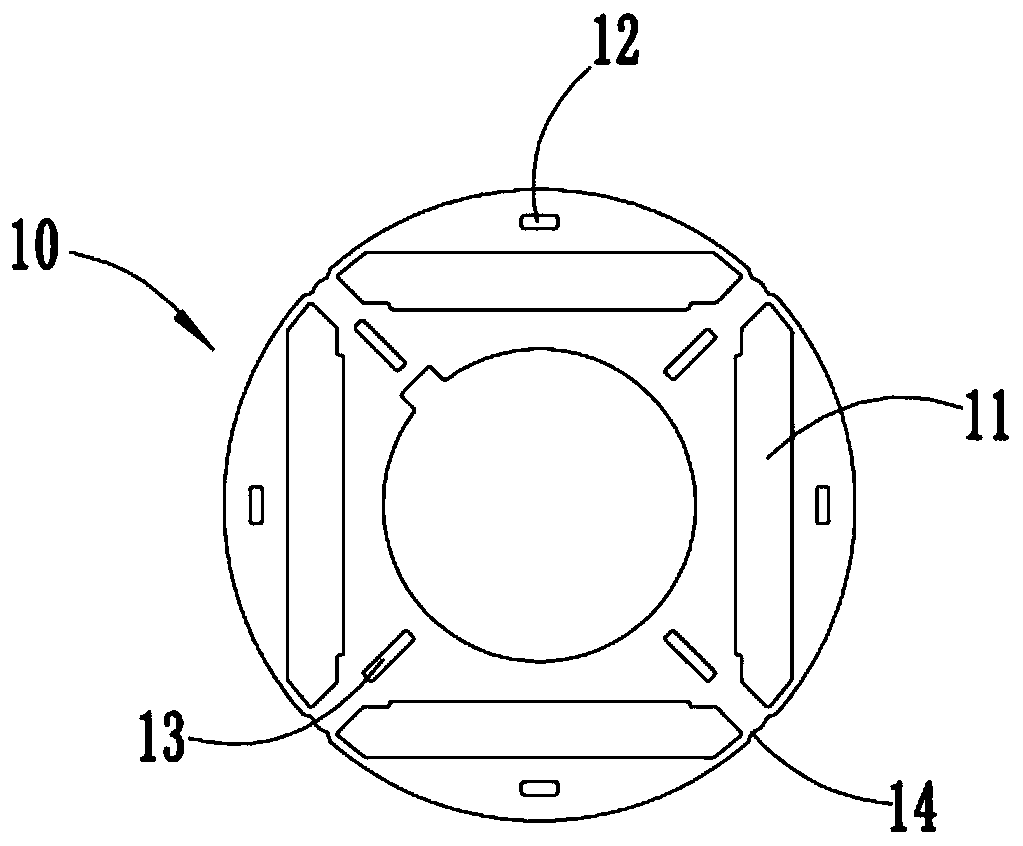

[0034] refer to figure 1 In the permanent magnet motor rotor processing technology provided in this embodiment, firstly, the parts to be stamped are stamped by a self-stacking riveting press to form a rotor piece 10 with a rotor groove 11, a riveting area and a welding joint 14, and then, the rotor piece 10 is dropped At the material station, the rotor slices 10 that are blanked each time are stacked on the previous punched rotor slice 10, and the two adjacent rotor slices 10 that are stacked together cooperate with each other through the riveting area, and there is no need to pass through the copper rod. To limit the position, the self-stacking riveting press presses down the upper mold of the blanking station, that is, the uppermost rotor piece 10 is stacked and riveted on the lower adjacent rotor piece 10, and the upper mold works continuously to form the adjacent rotor piece 10 are mutually riveted rotor cores. At this time, the axes of the rotor segments 10 of the rotor c...

Embodiment 2

[0068] This embodiment provides a rotor assembly, which is manufactured by the above-mentioned permanent magnet motor rotor processing technology.

[0069] The rotor assembly provided in this embodiment is manufactured by adopting the above-mentioned permanent magnet motor rotor processing technology, which ensures that the rotor cores are relatively fixed during the use of each adjacent rotor piece 10, and meets the use requirements of the permanent magnet motor. At the same time, the rotor The entire processing procedure is also less, reducing production costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com