Method and device capable of allowing workpieces to pass through unidirectionally and automatically protecting workpieces against backflow

A workpiece and automatic technology, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problem that the mechanical stopper cannot automatically follow the workpiece feeding and spacing, etc., to achieve the addition of manual adjustment function, convenient operation, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

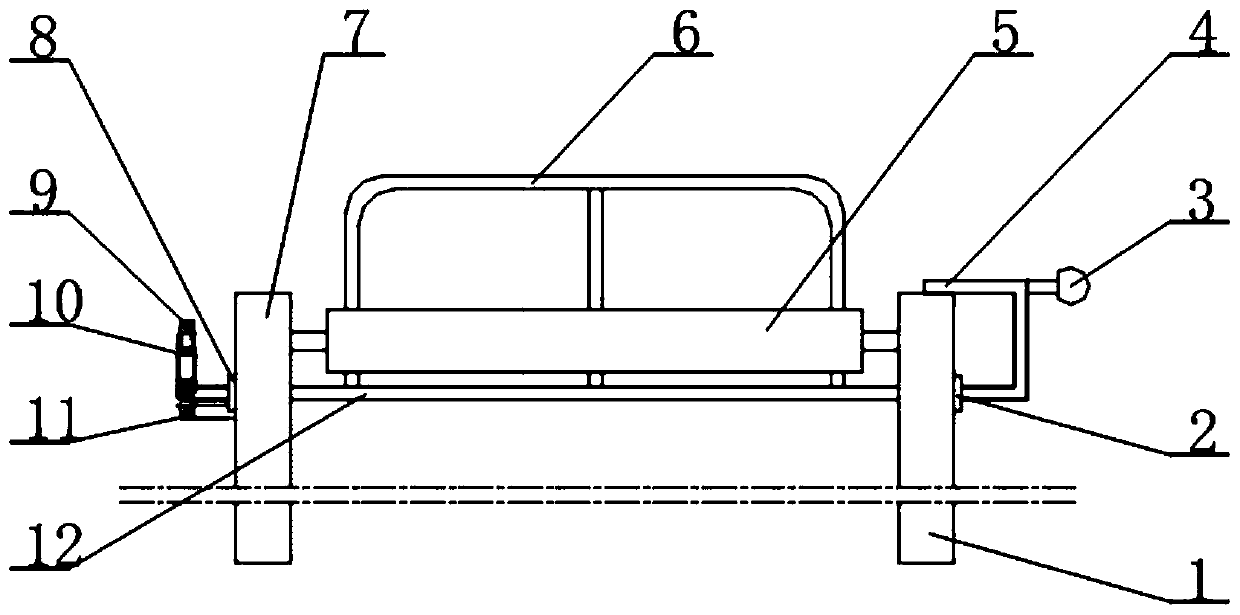

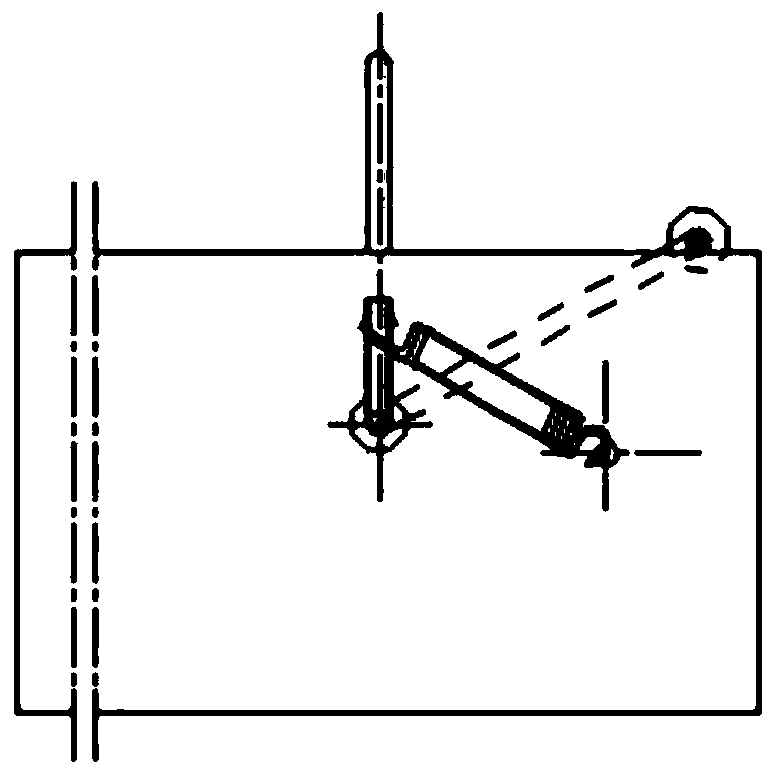

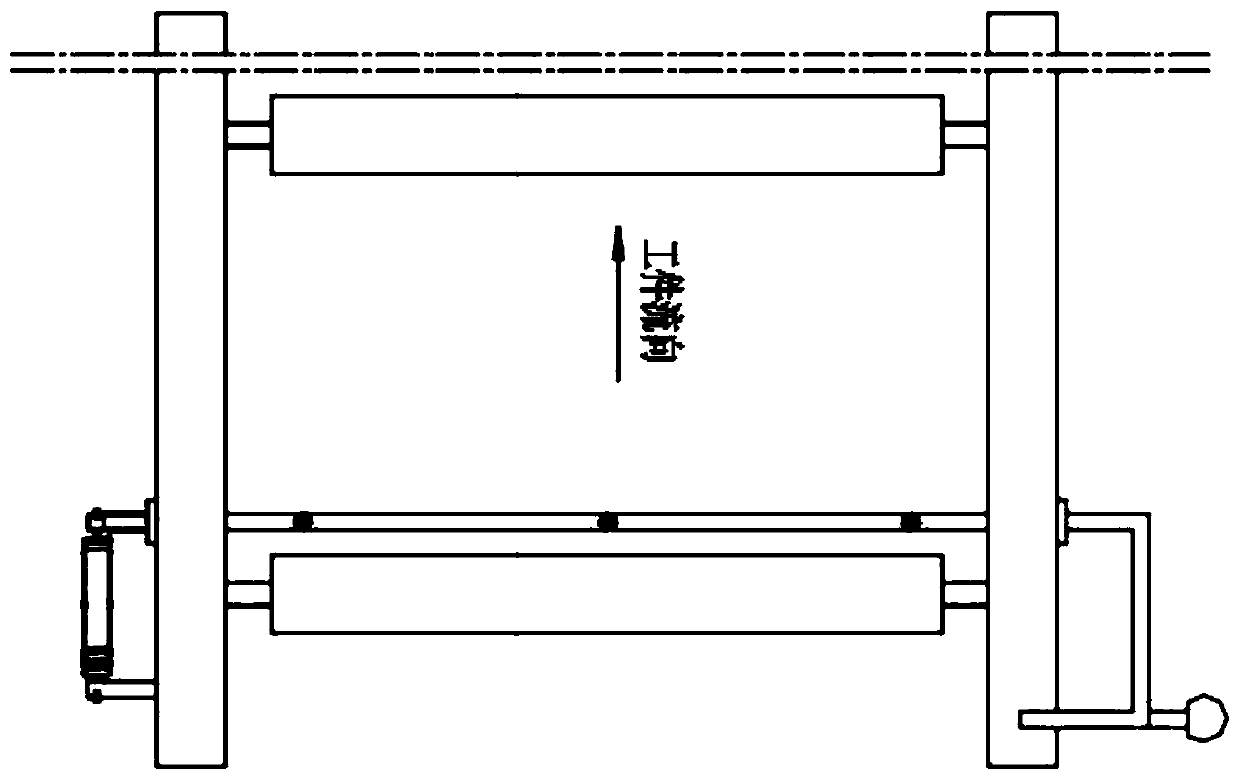

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the invention is not limited by the specific embodiment. It should be understood that the "up", "down", "left" and "right" directions mentioned in the following embodiments of the invention are all based on the positions of the corresponding drawings. These words used to limit the direction are only for convenience of description, and do not represent limitations on the specific technical solutions of the invention. Unless otherwise specified, the same reference numerals represent the same structure.

[0030] A method for unidirectionally passing workpieces and automatically preventing workpieces from returning, which mainly includes: setting a material separation mechanism on the raceway, and setting a stop rod assembly 6 that rotates around the mandrel 12 on the material separation mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com