Monitoring device of roller state, calendering device, and monitoring method of roller state

The technology of a monitoring device and a calendering device is applied in the field of monitoring devices for the state of rolls, and can solve problems such as sheet thickness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail based on preferred embodiments while referring to appropriate drawings.

[0025] 【Calendering device】

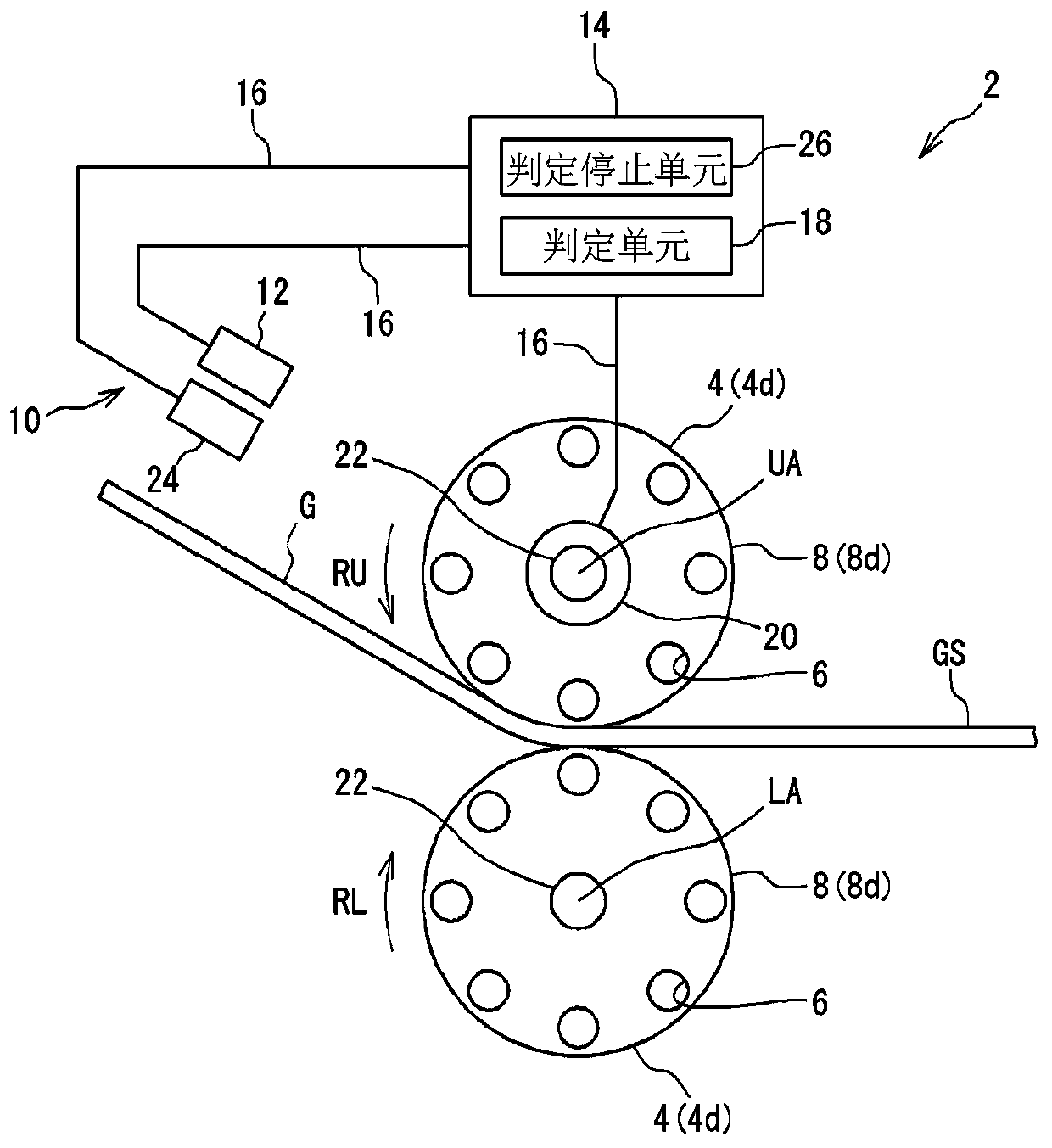

[0026] figure 1 It is a schematic diagram showing an outline of a rolling apparatus 2 according to an embodiment of the present invention. The calendering device 2 has a plurality of rolls 4 .

[0027] figure 1 The calendering device 2 shown has two rollers 4 arranged one above the other. In this rolling device 2 , the upper roll 4 and the lower roll 4 are arranged such that the axis UA of the upper roll 4 and the axis LA of the lower roll 4 are substantially parallel to each other. In the present invention, substantially parallel means that the angle formed by the axis LA with respect to the axis UA is in the range of 0° to 5°.

[0028] Although not shown in the figure, this rolling device 2 has a rotation unit (for example, a motor) that rotates the roll 4 at a predetermined rotation speed. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com