A shock absorbing device and a passenger elevator car

A shock absorbing device and compression spring technology, which is applied to elevators in buildings, transportation and packaging, non-rotational vibration suppression, etc., can solve the problem of accelerated aging of shock absorbing springs, easy aging, shortened service life of shock absorbing devices, etc. problems, to achieve the effect of avoiding premature aging, avoiding bloated structure and effective shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

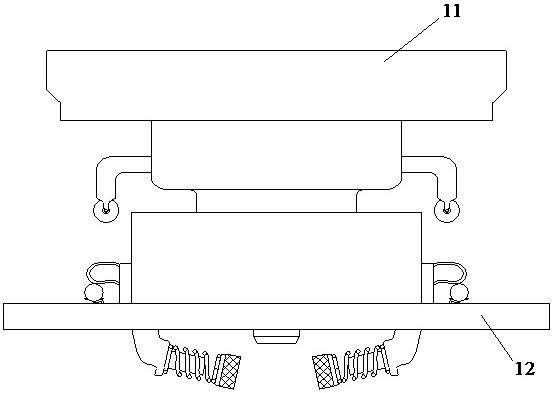

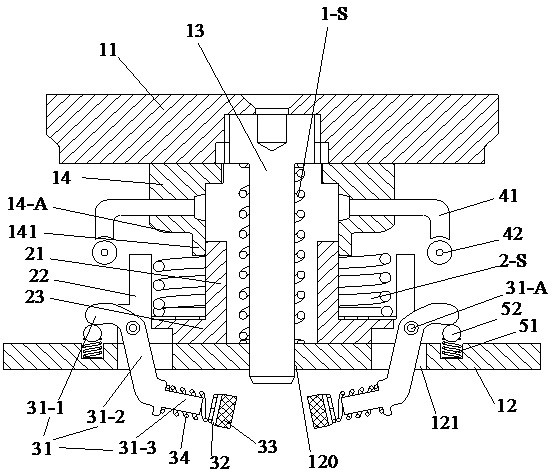

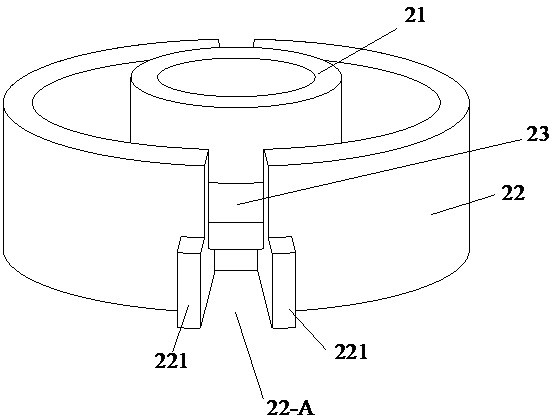

[0033] refer to Figure 1-Figure 3 , a shock absorbing device, comprising an upper seat plate 11, a lower seat plate 12, a guide pin 13, an inner ring compression spring 1-S, the upper seat plate 11 and the lower seat plate 12 are arranged horizontally, and the middle part of the lower seat plate 12 has The through hole 120, the guide bolt 13 is vertically arranged and the top is fixedly installed in the middle part of the bottom surface of the upper seat plate 11, and its bottom end can slide through the through hole 120 of the lower seat plate 12, considering that the upper seat plate 11 is used as For the parts directly under pressure, the firmness of the fixed connection between it and the guide pin 13 determines the stability of the downward movement under pressure. Therefore, the top end of the guide pin 13 can be set to a disc shape or a column shape with a large diameter. A matching groove is provided at the corresponding position on the bottom surface of the upper sea...

Embodiment example 2

[0045] refer to Figure 4 , a passenger elevator car, further comprising a car body 101, a bottom beam 102 installed under the car body 101, and at least two damping devices of Embodiment 1, the bottom beam 102 includes two angle steels 103, the The upper seat plate 11 of the damping device is fixed on the bottom surface of the car 101 base plate, and the lower seat plate 12 is symmetrically fixed on the top surfaces of two angle steels 103 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com