Pump body assembly and compressor

A technology of compressors and components, which is applied in the field of compressors and can solve problems such as compressor performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

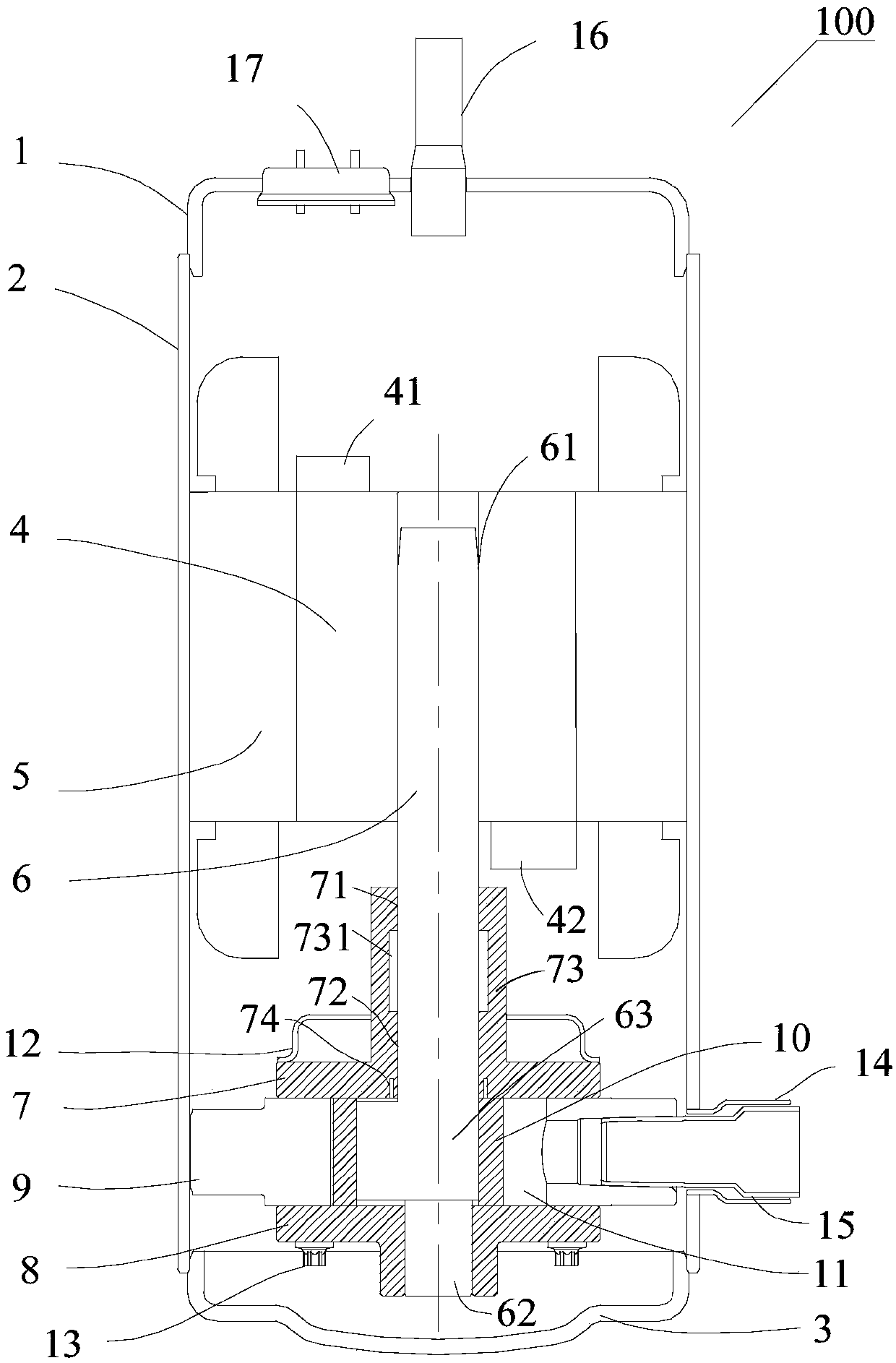

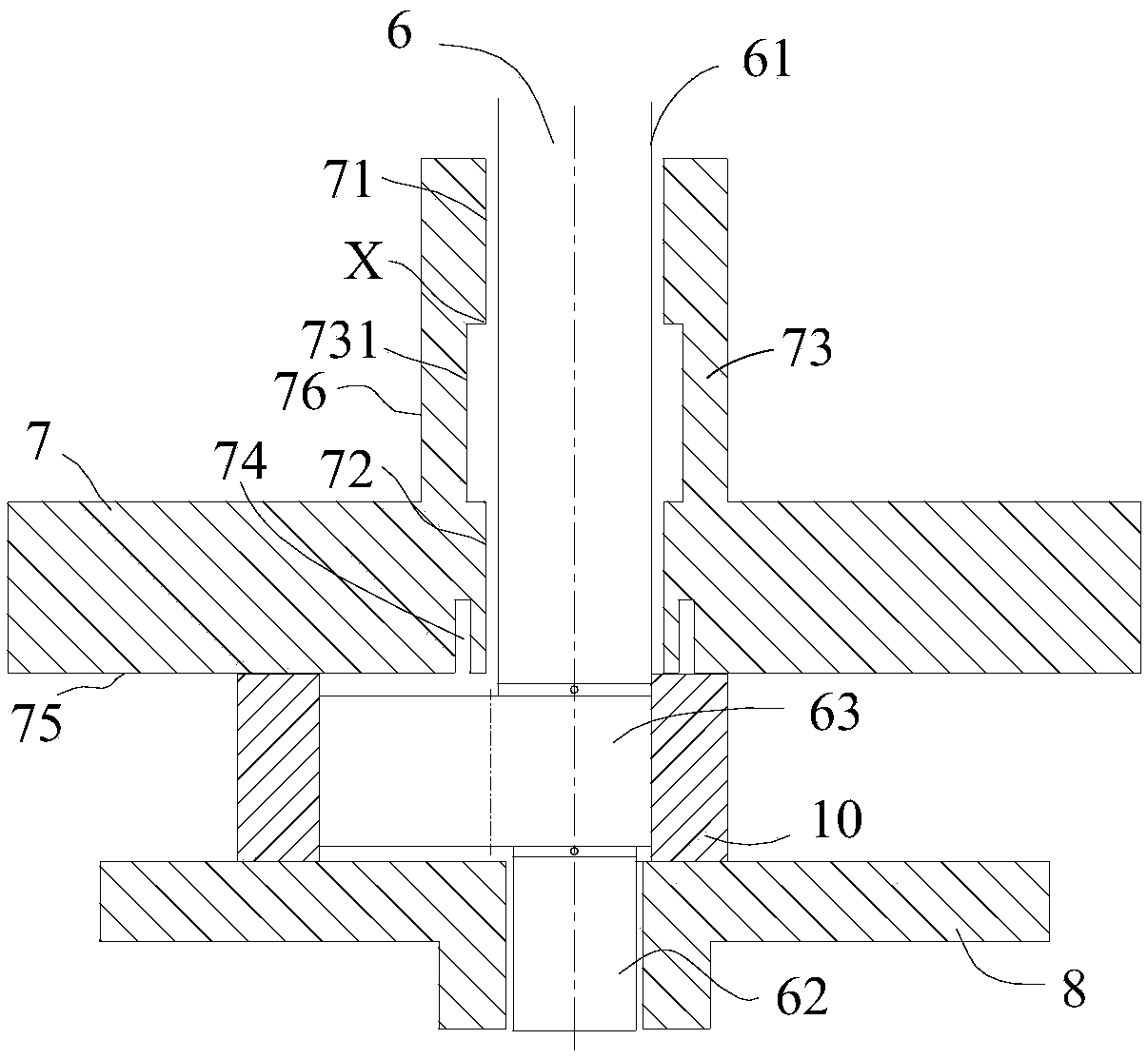

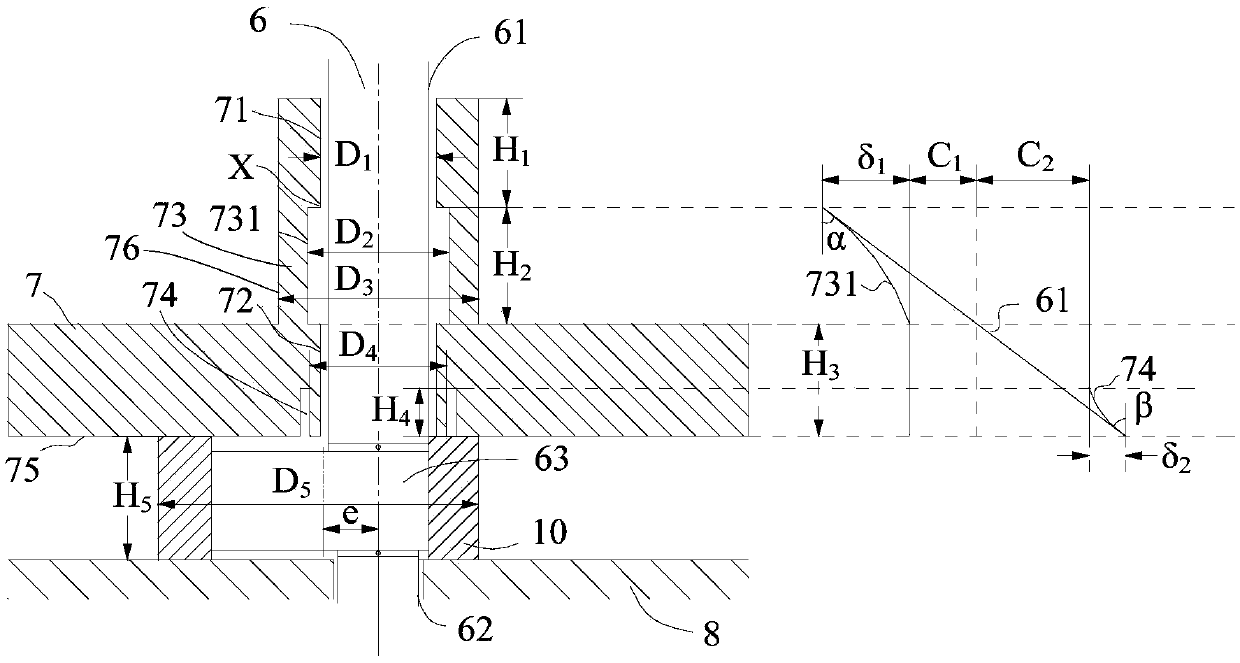

[0136] Such as Figure 1 to Figure 3 As shown, the pump body assembly includes a crankshaft 6, a first bearing 8 and a second bearing 7, one end of the crankshaft 6 is used to connect the motor of the compressor 100; the first bearing 8 is sleeved on the other end of the crankshaft 6; the second bearing 7 Sleeved on the crankshaft 6, the second bearing 7 includes a first bearing segment 71, a gap bearing segment 73 and a second bearing segment 72 which are sequentially connected from top to bottom; wherein, the inner side wall of the gap bearing segment 73 is provided with a bearing recess Groove 731 , the second bearing 7 also includes a second bearing annular groove 74 surrounding the crankshaft 6 , the second bearing annular groove 74 is located on the end wall of the second bearing section 72 facing the first bearing 8 , that is, the second bearing bottom wall 75 .

[0137] Such as Figure 9 As shown, when the compressor is running, the crankshaft 6 is subject to the cent...

Embodiment 2

[0149] Such as Figure 4 with Figure 5 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, the only difference is that the groove of Embodiment 1 is on the second bearing 7 and divides the second bearing 7 into a first bearing segment 71 and a second bearing segment 72 In this embodiment, the groove is arranged on the crankshaft 6, so that the main shaft 61 corresponding to the crankshaft 6 and the second bearing 7 is divided into the first main shaft section 611, the second main shaft section 613 and the crankshaft recess formed between them. Groove 612. The compressor 100 provided in Embodiment 2, based on the same principle as Embodiment 1, can improve the wear of the upper end of the second bearing 7 and the root of the second bearing 7, reduce the viscous resistance loss of the compressor 100, and improve the performance of the compressor 100. efficiency.

[0150] The geometric constraints and lubrication conditions defined in...

Embodiment 3

[0153] Such as Figure 6 As shown, the structure of this embodiment is substantially the same as that of Embodiment 2. On the basis of Embodiment 2, this embodiment adds a first bearing annular groove 81 to the first bearing 8 . The compressor 100 provided by Embodiment 3, based on the same principle as Embodiment 1 and Embodiment 2, can improve the wear of the upper end of the second bearing 7 and the root of the second bearing 7 and the root of the first bearing 8, and reduce the wear of the compressor 100. The viscous resistance loss improves the energy efficiency of the compressor 100 .

[0154] The geometric constraints and lubrication conditions defined in Embodiment 1 and Embodiment 2 are still applicable in Embodiment 3. In addition, the lubrication conditions to be satisfied by the first bearing annular groove 81 are:

[0155]

[0156] in,

[0157]

[0158] Such as figure 1 , Figure 4 with Figure 6 As shown, the embodiment of another aspect of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com