A high-speed spin-wave waveguide based on magnetic dipole interaction

A technology of spin wave and magnetic dipole, applied in the direction of waveguide, waveguide-type devices, circuits, etc., can solve the problems of complex manufacturing process of double-layer waveguide, difficult docking, unfavorable development of spin wave devices, etc., and is conducive to miniaturization , simple preparation process and wide application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

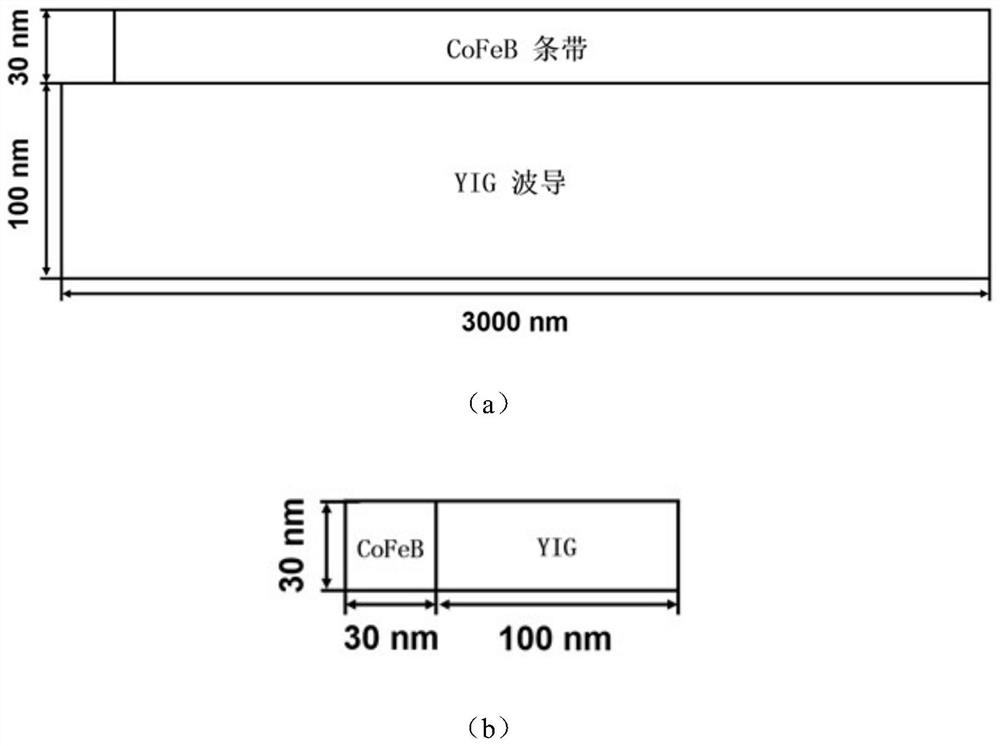

[0027] In this embodiment, the material of the ferrimagnetic rectangular strip is yttrium iron garnet (YIG), which has an extremely low Gilbert damping coefficient, and using it as a medium for spin wave transport greatly improves the propagation of spin waves distance. The specific parameters of the material are: saturation magnetization Ms=1.4×10 5 A / m, exchange constant A=3.5×10 -12 J / m, Gilbert damping coefficient α=2×10 -4 . The material of the ferromagnetic rectangular strips is CoFeB, which has a large saturation magnetization. Specific parameters of the material: saturation magnetization Ms=1.15×106 A / m, exchange constant A=1.6×10 -11 J / m, Gilbert damping coefficient α=5×10 -3 . The specific shape parameters of the spin-wave waveguide are as follows: figure 1 Shown: the length of the YIG waveguide is 3000nm, the width is 100nm, and the thickness is 30nm, and the length of the CoFeB strip is 2800nm, the width is 30nm, and the thickness is 30nm.

[0028] figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com