Clamping stamping type red date pitting machine

A punching and jujube technology, applied in the field of clamping punching jujube denucleating machine, can solve the problems of low denucleation efficiency, lack of protection, waste of jujube, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

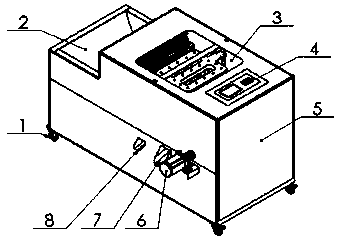

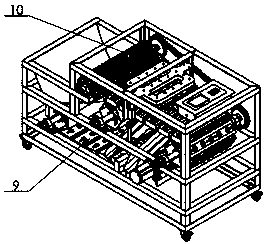

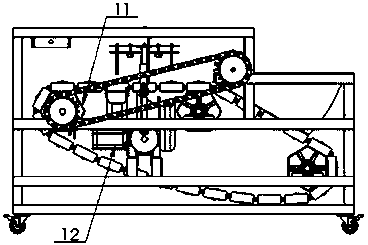

[0024] In order to achieve the above object, the present invention provides the following technical solutions: a clamping and stamping type jujube pitting machine, which mainly includes a feeding mechanism, a transmission mechanism, a nuclear mechanism, a discharge mechanism and a body (5), and is characterized in that: The feeding mechanism is composed of a hopper (2), a jujube chain plate (9), a brush roller (10), a track drive wheel (11), a jujube holder (26), etc., and the transmission mechanism is composed of a step Into the motor I (6), stepping motor II (12), drive shaft (16) and other components, the core removal mechanism is composed of pressing rod (19), removal rod (20), centralizing rod (21), upper The fixed plate (22), the buffer spring (23) and the lower fixed plate (24) are composed, the discharge mechanism is composed of the pitted jujube trough (7) and the jujube pit trough (8), and the top of the body is provided with Viewing window (3) and control panel (4)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com