Startup detection device of dust removal instrument, dust collector and startup detection method

A detection device and technology for vacuum cleaners, which are applied in the installation of vacuum cleaners, electrical equipment, cleaning equipment, etc., can solve the problem of inability to automatically detect whether the dust collecting cup body is assembled in the vacuum cleaner, etc., so as to reduce the dust removal efficiency and service life, and improve the accuracy. and stability, wasting time and stamina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a power-on detection device for a dust removal instrument (hereinafter, the power-on detection device for a dust removal device is simply referred to as a power-on detection device), which can be applied to a dust removal device so that the dust removal device can automatically detect whether a dust collection cup is assembled when the dust removal device is started body. The dust removal device mentioned above refers to a container (such as a dust collection cup, a dust collection box, etc.) that can collect dust, waste or hair. Dust collection) instruments, such as vacuum cleaners, mite removers, sweeping robots, etc.

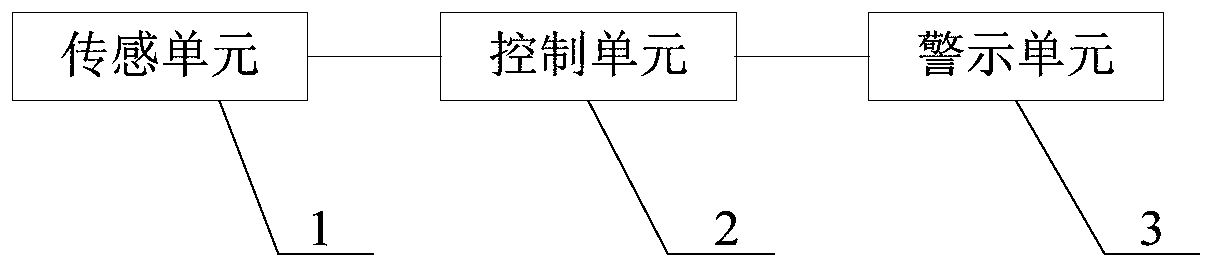

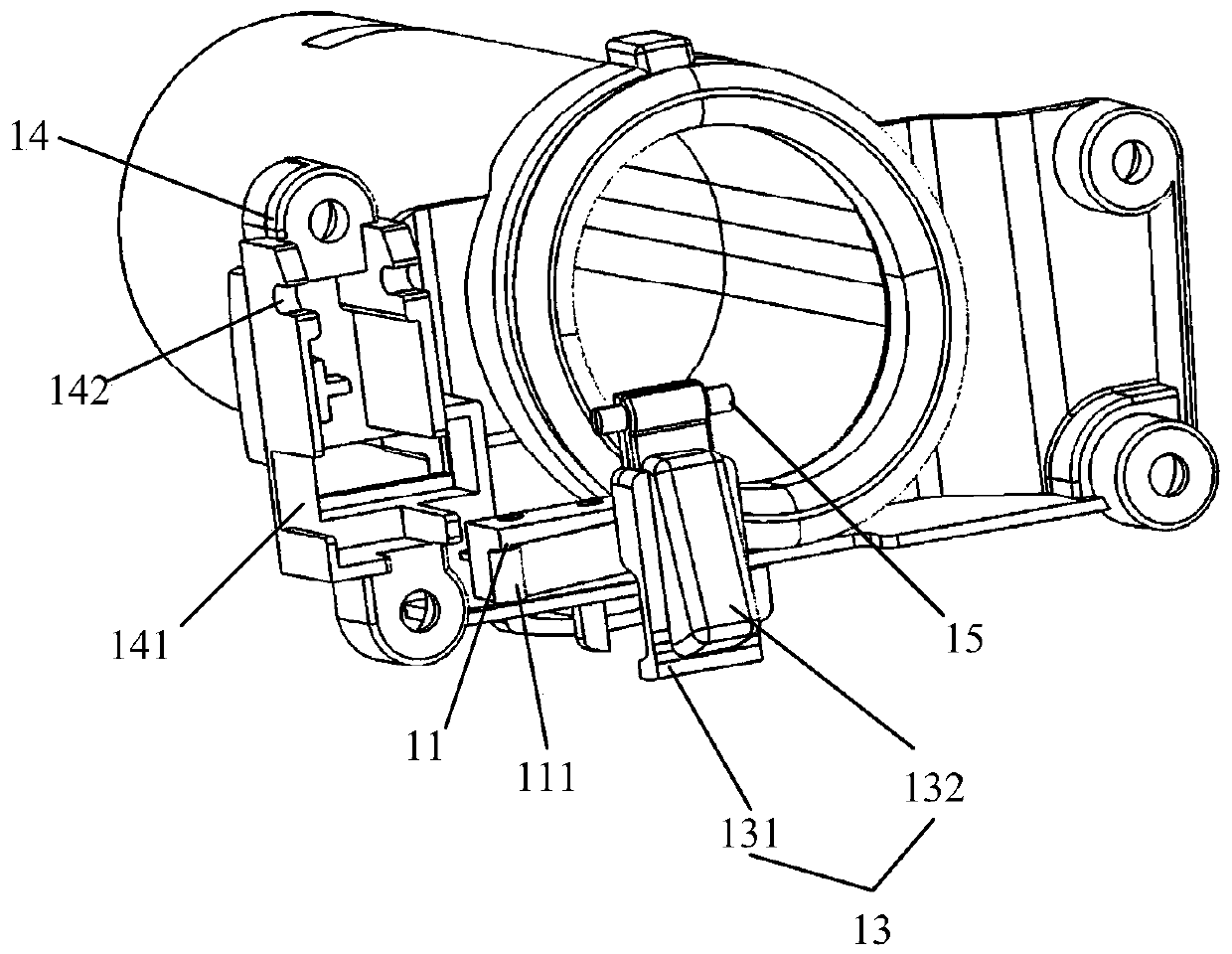

[0049] Such as Figure 1 to Figure 7 As shown, the power-on detection device includes a sensing unit 1, a control unit 2, and a warning unit 3. The control unit 2 is connected to the sensing unit 1 and the warning unit 3 respectively. The sensing unit 1 is used to detect whether the dust removal instrument is equipped with a d...

Embodiment 2

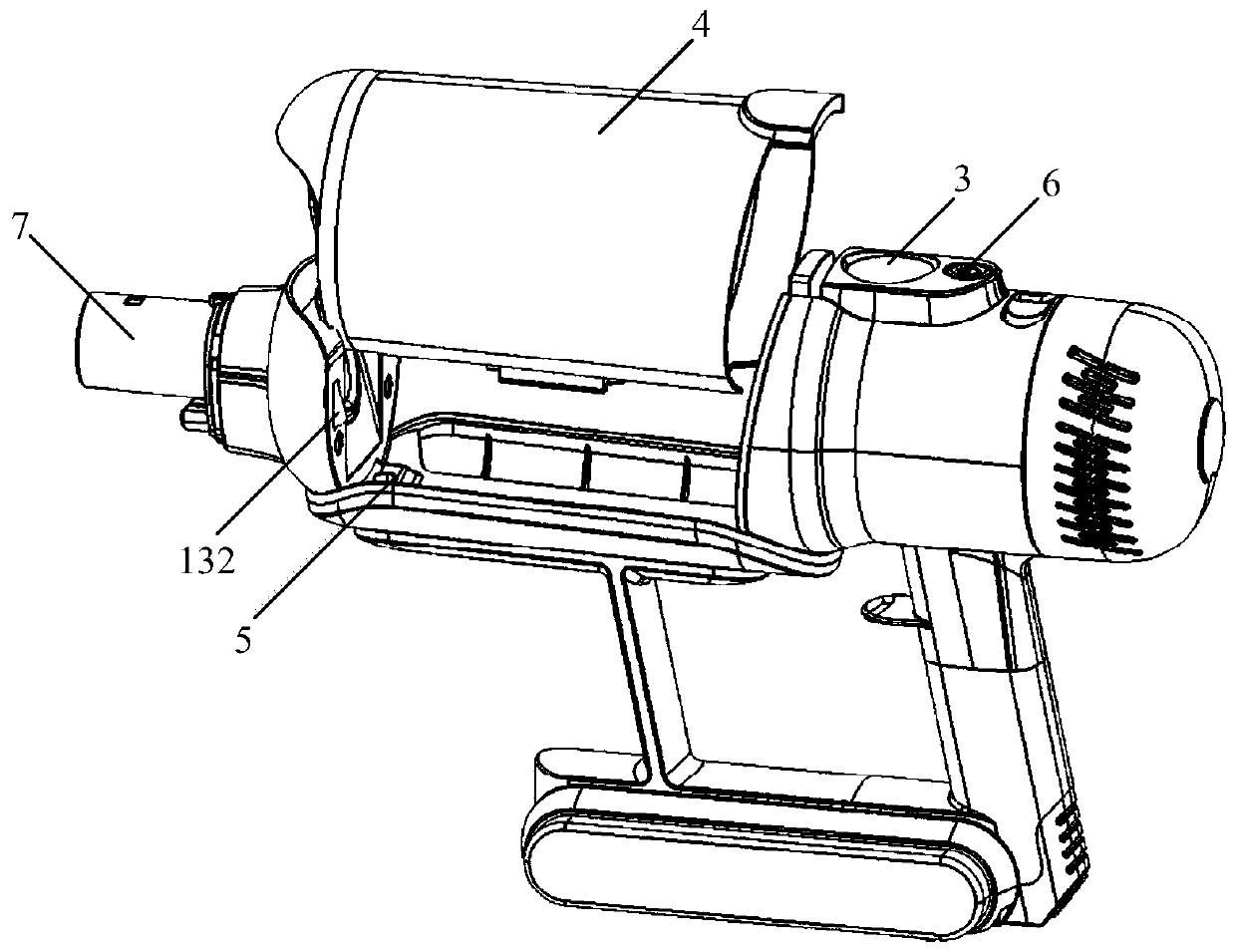

[0082] This embodiment provides a vacuum cleaner, such as Figure 3-Figure 7 As shown, it includes the start-up detection device of the dust removal instrument provided in the first embodiment, the dust collecting cup 4 and the main body of the housing.

[0083] The housing body is provided with an assembly chamber 5 for assembling the dust collection cup 4 , and the assembly chamber 5 matches the shape of the dust collection cup 4 . In this embodiment, the assembly cavity 5 is located in the middle of the housing body.

[0084] The sensing unit 1 , the control unit 2 and the warning unit 3 of the power-on detection device are respectively connected to the power supply unit of the vacuum cleaner, and the power supply unit provides the required electric energy for the power-on detection device. In this embodiment, the power switch 6 of the power supply unit is arranged on the top end surface of the housing main body.

[0085] The control unit 2 is installed in the housing mai...

Embodiment 3

[0098] This embodiment provides a vacuum cleaner startup detection method, which is used for the vacuum cleaner startup detection provided in Embodiment 2, including the following steps:

[0099] Step 1: Turn on the power switch 6 of the vacuum cleaner;

[0100] Step 2: The sensing unit 1 detects whether the dust collecting cup exists, and sends the generated signal to the control unit 2;

[0101] Specifically, the sensing unit 1 detects the dust collecting cup 4, and if the dust collecting cup 4 is detected, a signal is generated and sent to the control unit 2, and if the dust collecting cup 4 is not detected, no signal is sent to the control unit 2:

[0102] Step 3: The control unit 2 controls whether the motor is turned on and whether to send an instruction to the warning unit 3 according to the signal transmitted by the sensing unit 1 .

[0103] Specifically, within a predetermined time, if the number of signals received by the control unit 2 is equal to the number of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com