Sorting machine for testing electronic components

A technology of electronic components and sorting machines, applied in sorting and other directions, can solve problems such as differences in recognition rates, test errors, broken glass materials, etc., and achieve the effects of precise mutual positions, improved reliability, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] According to the preferred embodiments of the present invention described with reference to the drawings, the description of substantially the same constituent elements is omitted as much as possible for the sake of brevity of description.

[0078]

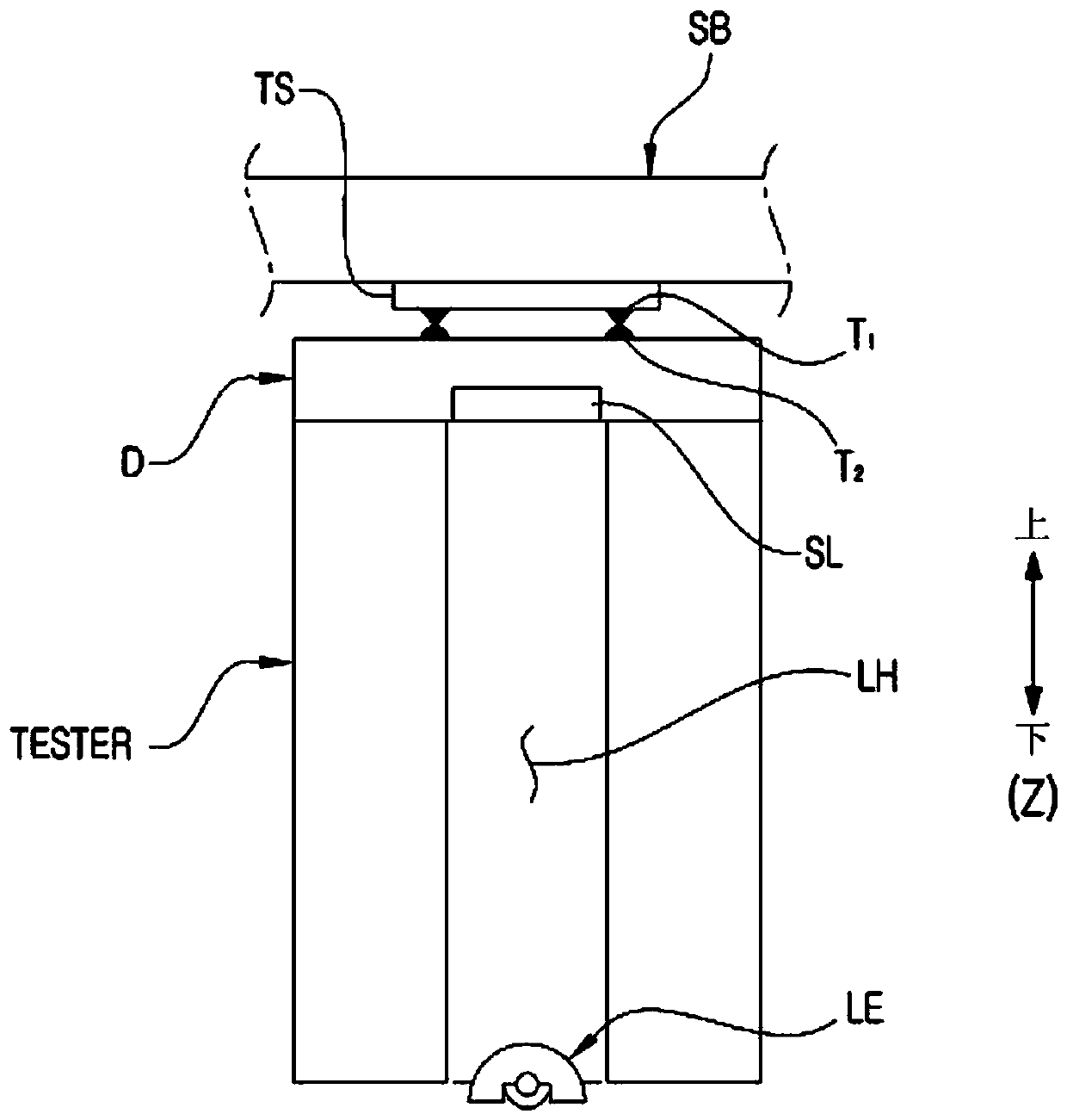

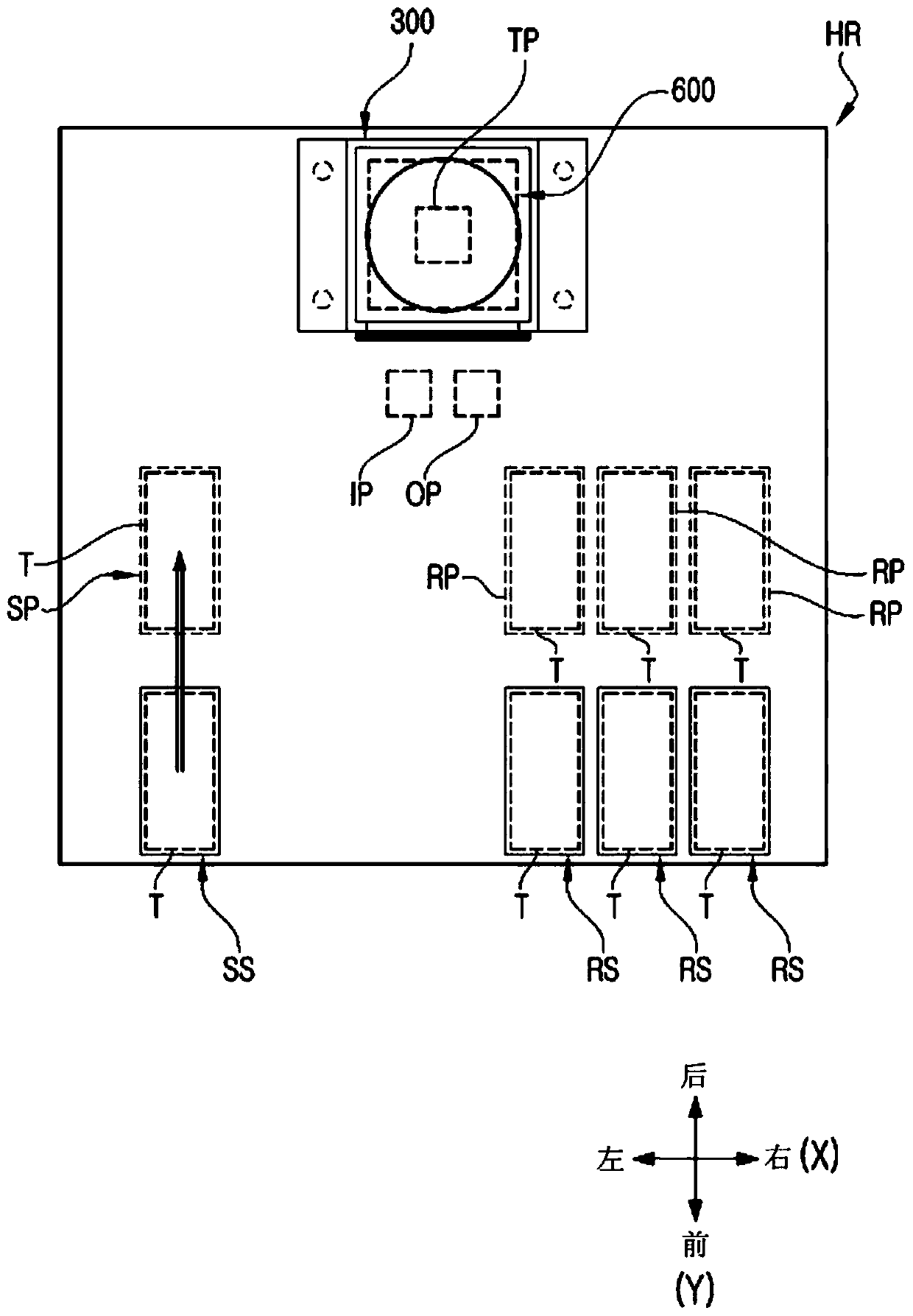

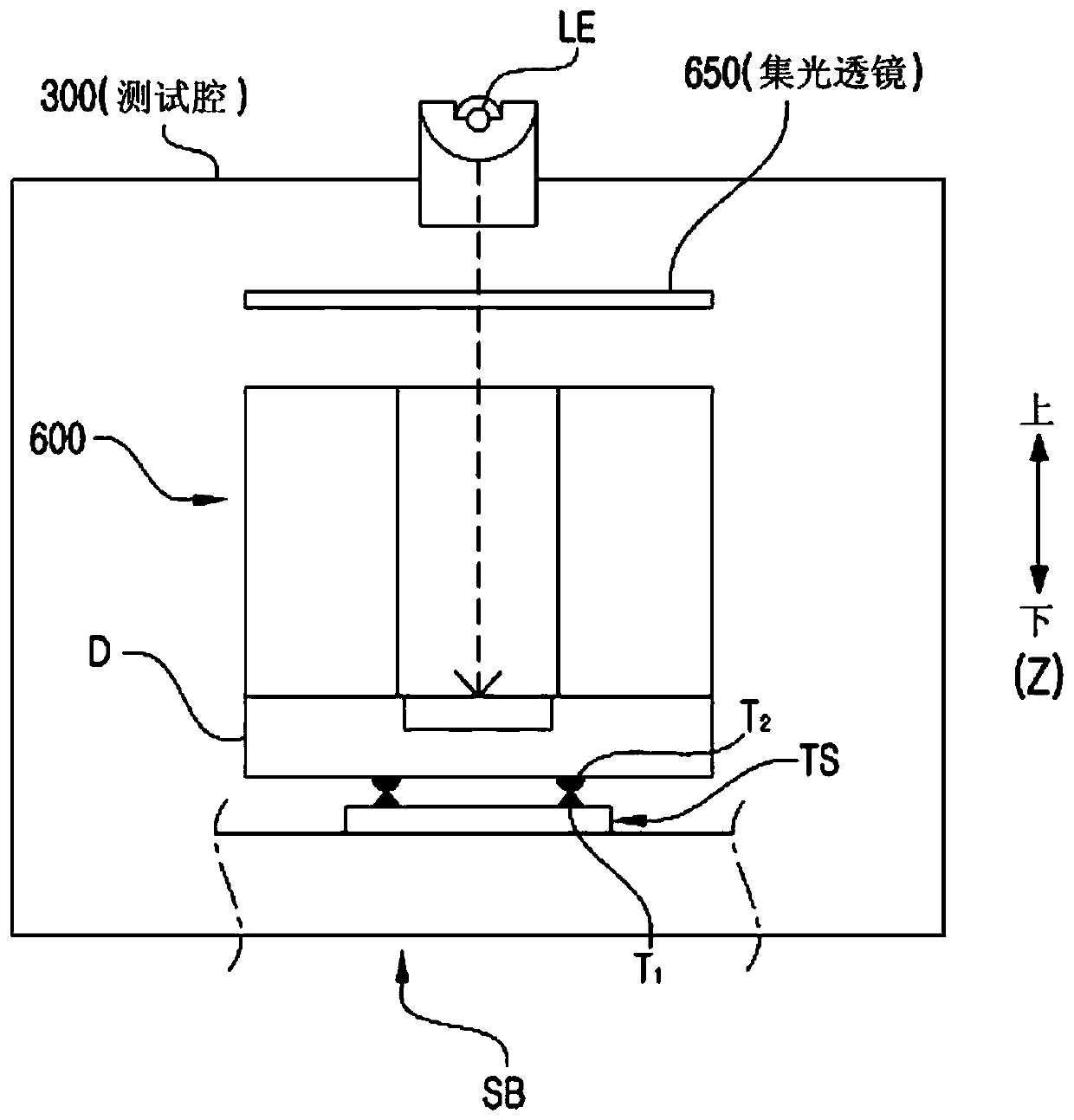

[0079] figure 2 is a conceptual plan view for explaining the movement of electronic components in the sorter HR according to the present invention.

[0080] The electronic components are moved from the supply stacker SS to the supply position SP in the state loaded on the tray T, and are unloaded from the tray T in groups of four, and then moved from the supply position SP to the bring-in position IP. And, if the electronic part is moved from the bring-in position IP to the test position TP within the test cavity 300, the pressurizing device 600 operates to electrically connect the electronic part to the tester, and then the electronic part is tested. Here, test slots for electrically connecting electronic components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com