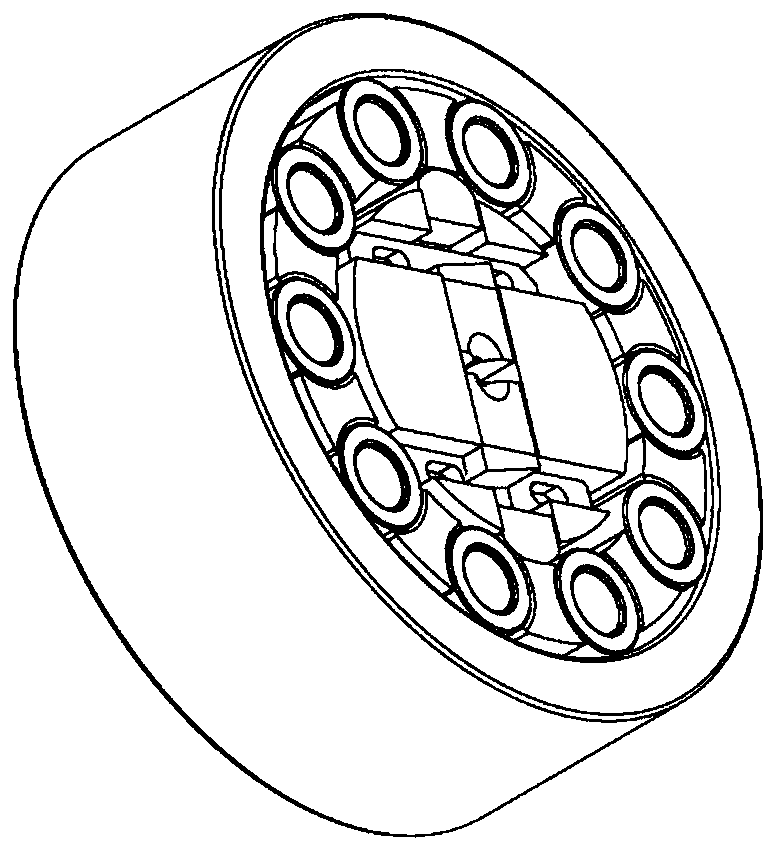

Head shrinkage tool of ultra-small semi-hard cable

An ultra-small, cable technology, which is used in the field of cable production and cold processing of solid bodies, can solve the problems that it is difficult to prevent the copper tube from slipping out of the mold, and the way of pushing the feed is difficult to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

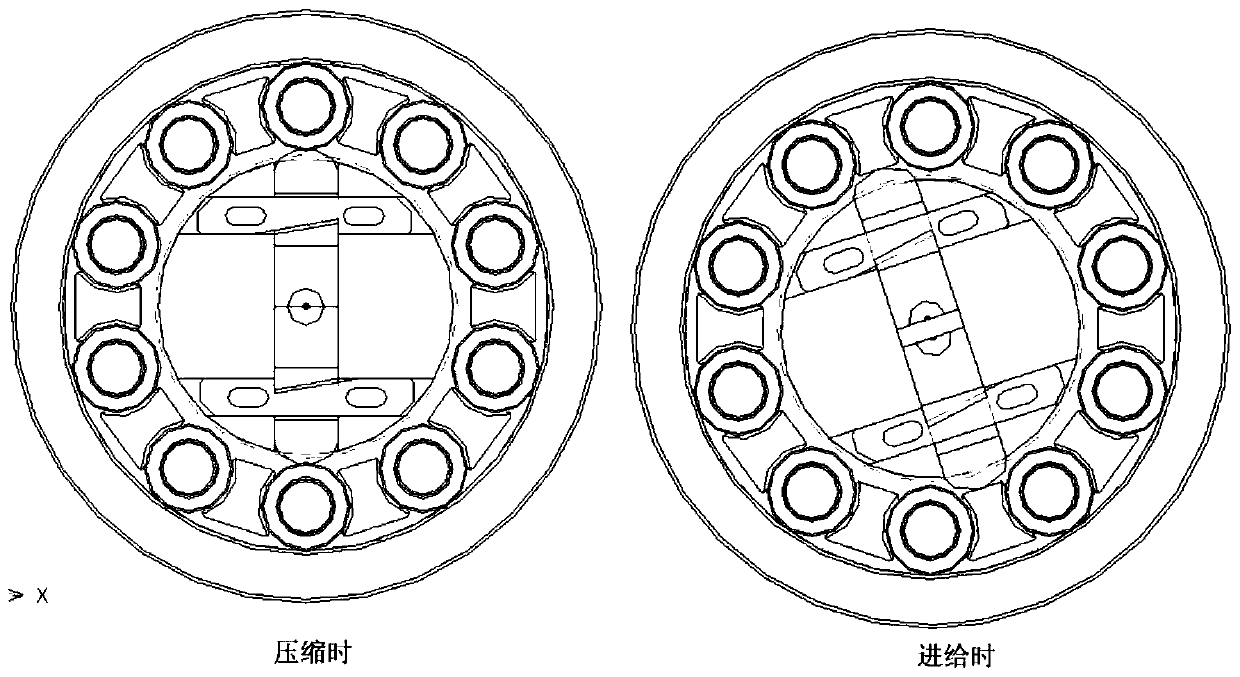

Method used

Image

Examples

Embodiment 2

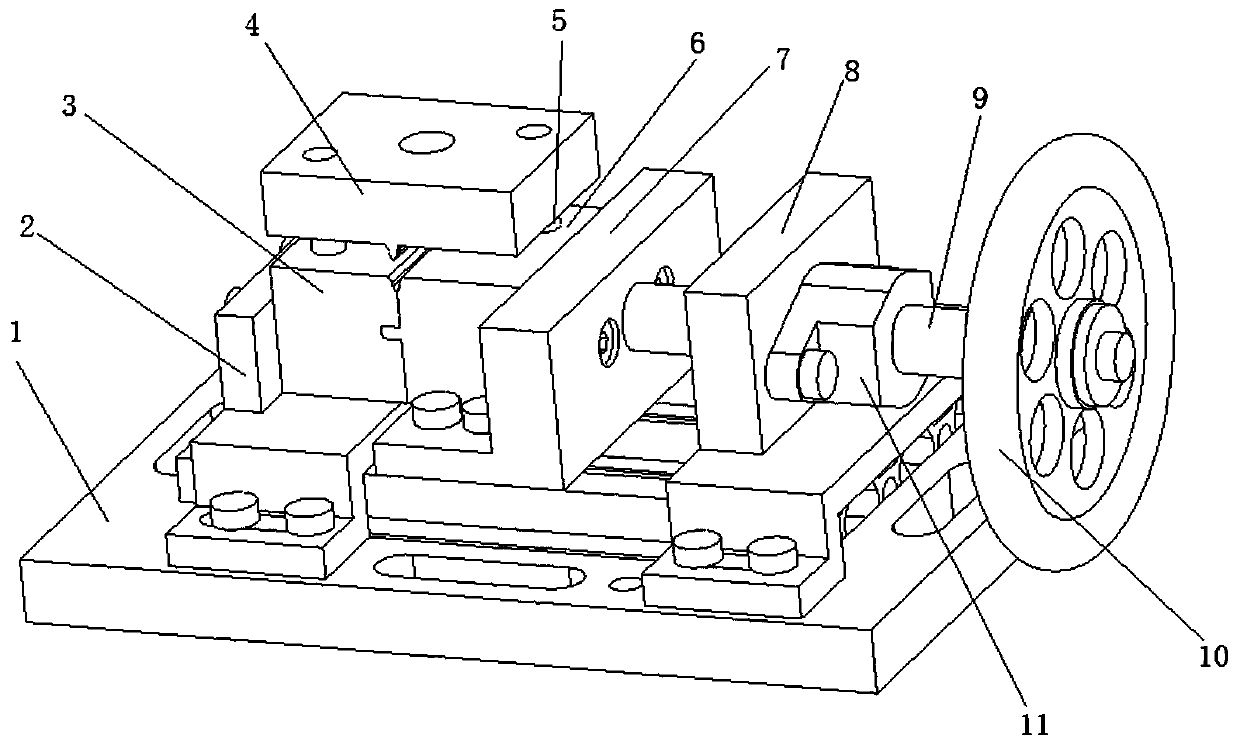

[0035] Embodiment 2, the setting positions of the V-shaped groove and the V-shaped protrusion can be replaced by: the lower surface of the upper mold 4 is provided with a V-shaped groove, and the upper surface of the lower mold is provided with a V-shaped protrusion that cooperates with the V-shaped groove of the upper mold 4. Shaped protrusion is formed by splicing of fixed mold 3 and sliding mold 6.

[0036] In the above-mentioned two embodiments, what needs to be specially explained is that the size and position design of the V-shaped groove and the positioning groove in the present invention are as follows:

[0037] (1) V-groove design

[0038] The V-shaped groove is the stamping die for the first stamping of the outer conductor of the cable into a V-shape, and its size requirements are as follows: Figure 6 It is shown in the upper mold structure diagram. The key dimensions include: the angle of the V-shaped groove is θ, the width of the V-shaped groove is b1, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com