High-speed intelligent pillow-type packaging machine

A pillow packaging machine, intelligent technology, applied in the direction of packaging, transportation packaging, multiple packages, etc., can solve the problems of short heat sealing time, poor bag sealing, low production efficiency, etc., to optimize the working environment and improve Sealing effect, effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

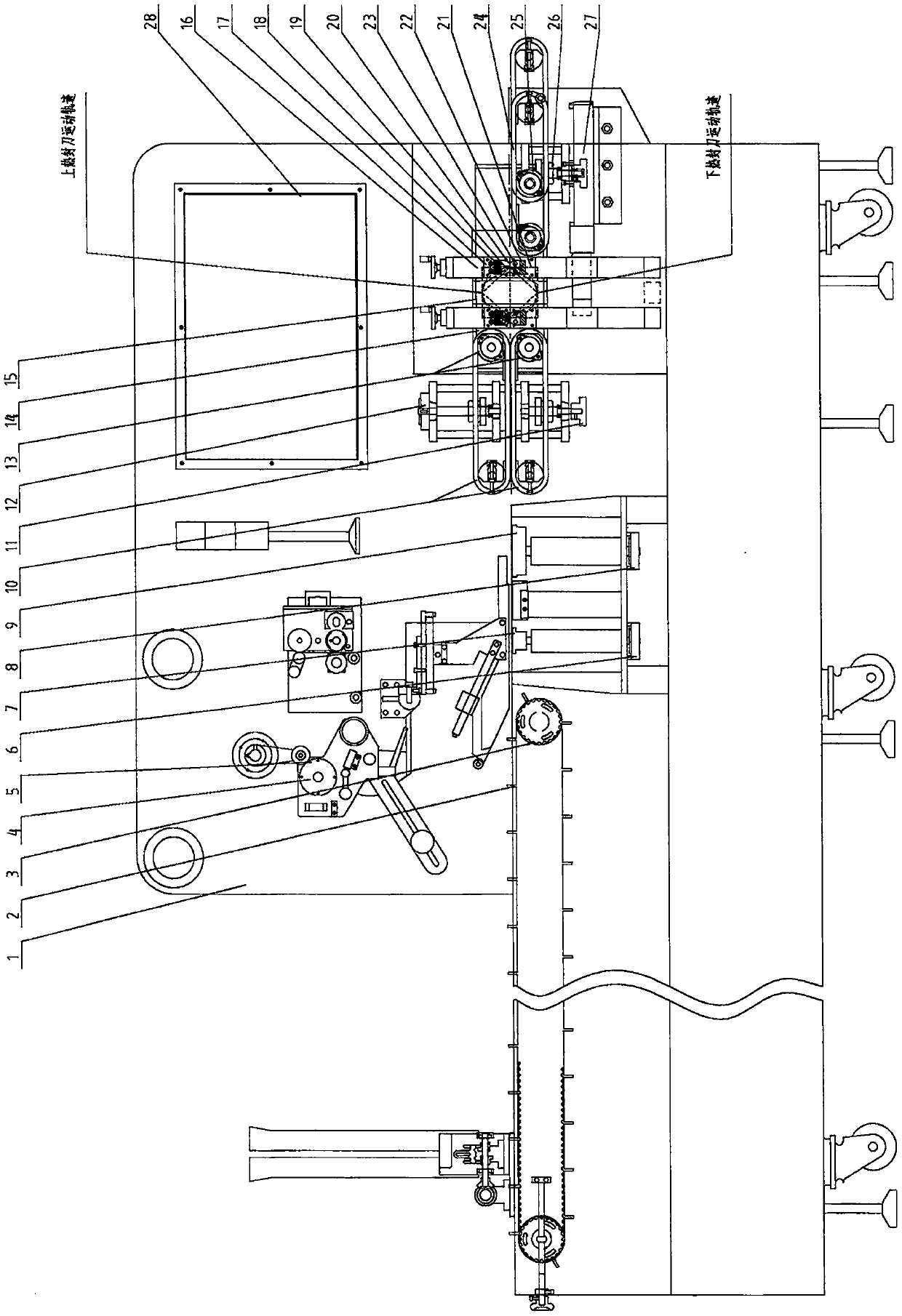

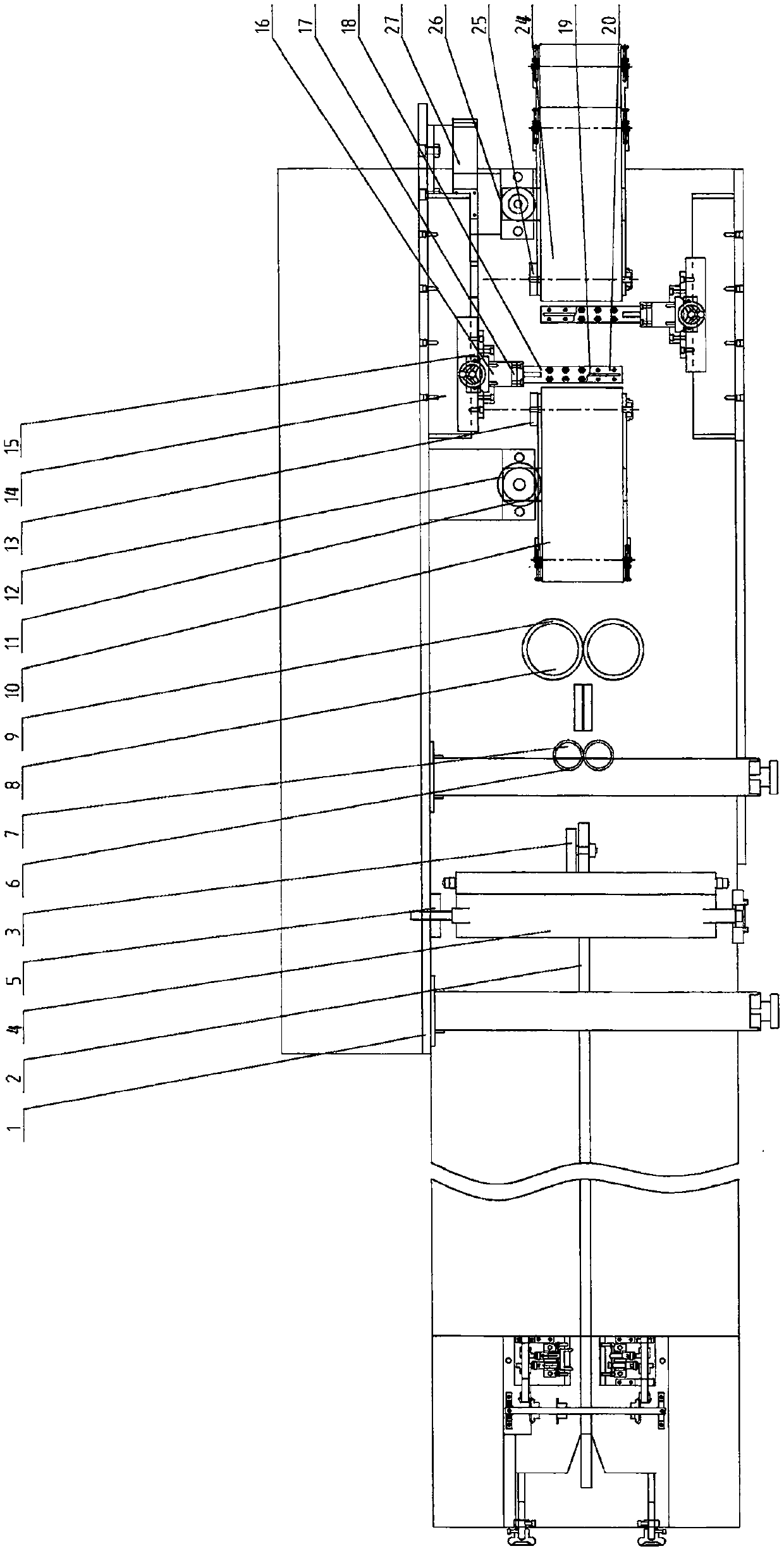

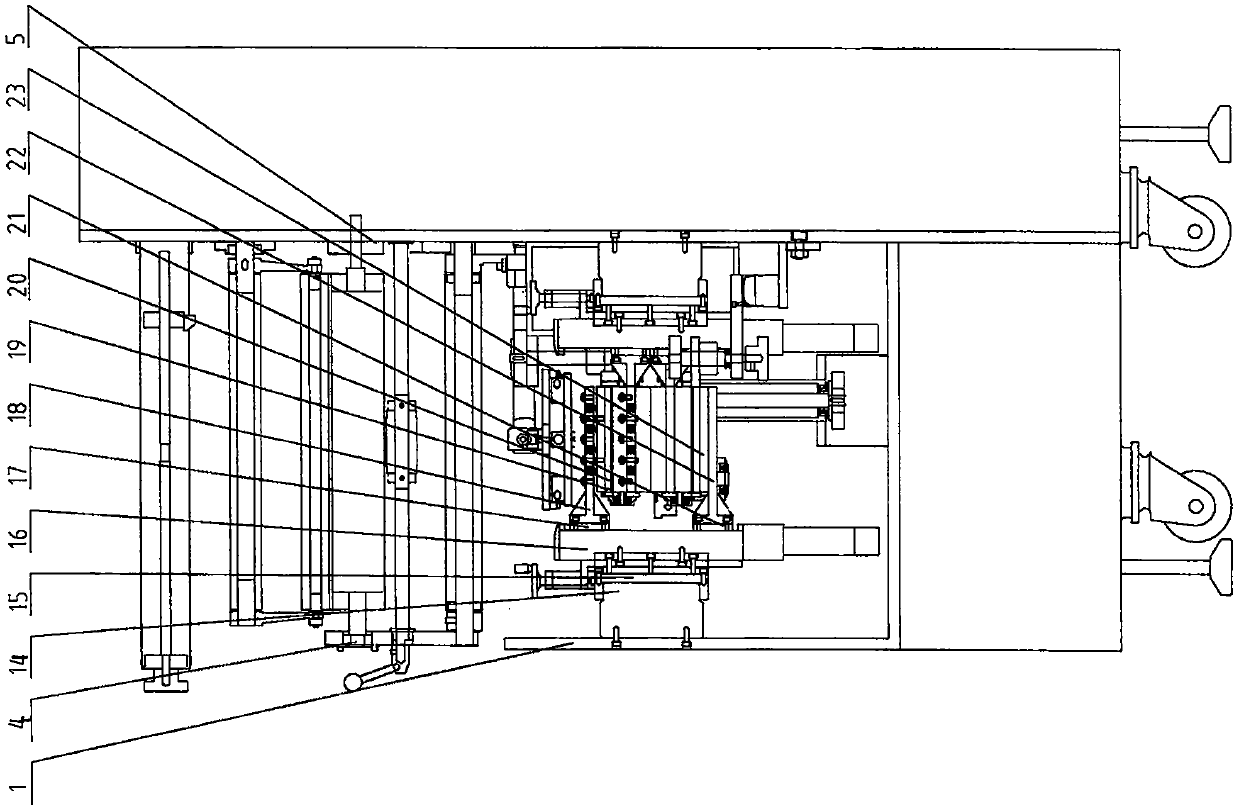

[0012] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0013] refer to Figure 1 to Figure 4 It can be seen that the high-speed intelligent pillow packaging machine of the present invention includes a main frame archway 1, on which a main frame archway 1 is sequentially (from left to right) equipped with a material conveying mechanism (comprising a septum timing belt assembly 2, a material conveying rotary power Source 3), film conveying mechanism (including traction roller 4, traction roller rotation power source 5), film traction longitudinal sealing mechanism (including traction wheel rotation power source 6, traction wheel 7 and longitudinal sealing knife, embossing wheel rotation power source 8. Longitudinal sealing embossing wheel 9), feeding mechanism (including feeding friction belt assembly 10, feeding rotating power source 13, feeding upper regulator 12, feeding lower regulator 11), f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com