Long-strip-body detection steering and distributing conveying mechanism

A technology of conveying mechanism and strip body, which is applied in the field of strip body detection, steering, material distribution conveying mechanism, and can solve the problems of slow response speed and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

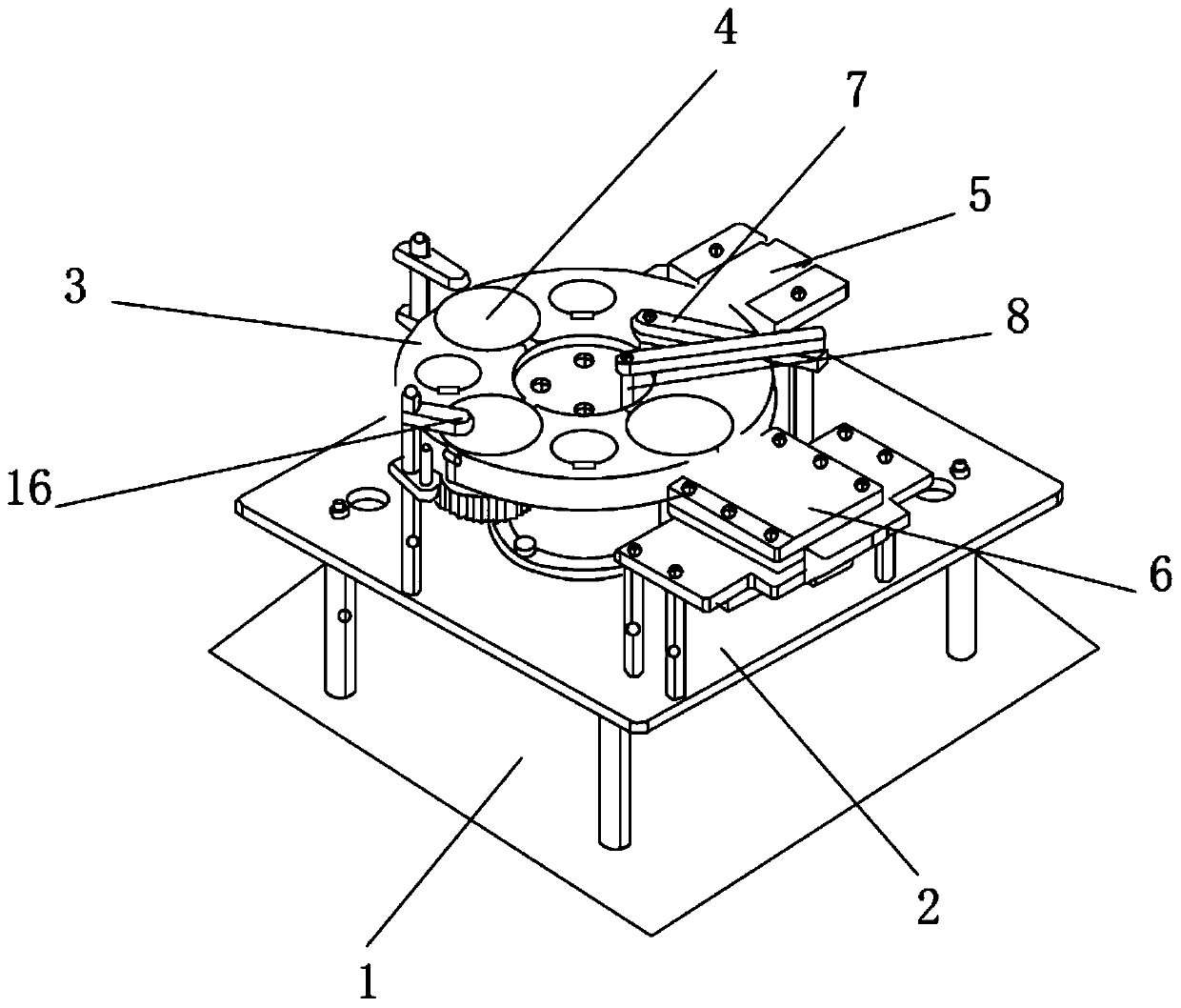

[0023] refer to Figure 1-3 , a kind of elongated body detection turning material distribution conveying mechanism, comprises frame 1, and bottom plate 2 is installed on the top surface of frame 1, and the top surface bolt of bottom plate 2 is connected with big turntable 3, and the top surface of big turntable 3 is installed with small The feed system 5 is installed on the side of the turntable 4 and the large turntable 3, and the discharge system 6 is installed on the side of the large turntable 3 corresponding to the feed system 5, and the top surface of the large turntable 3 corresponds to the feed system 5 and the discharge system. The position between the systems 6 is provided with an in-position detection sensor 7, the bottom of the in-position detection sensor 7 is connected with an air nozzle 8, and the top surface of the large turntable 3 is equipped with a positive and negative detection sensor 16 on the side away from the in-position detection sensor 7.

[0024] By...

Embodiment 2

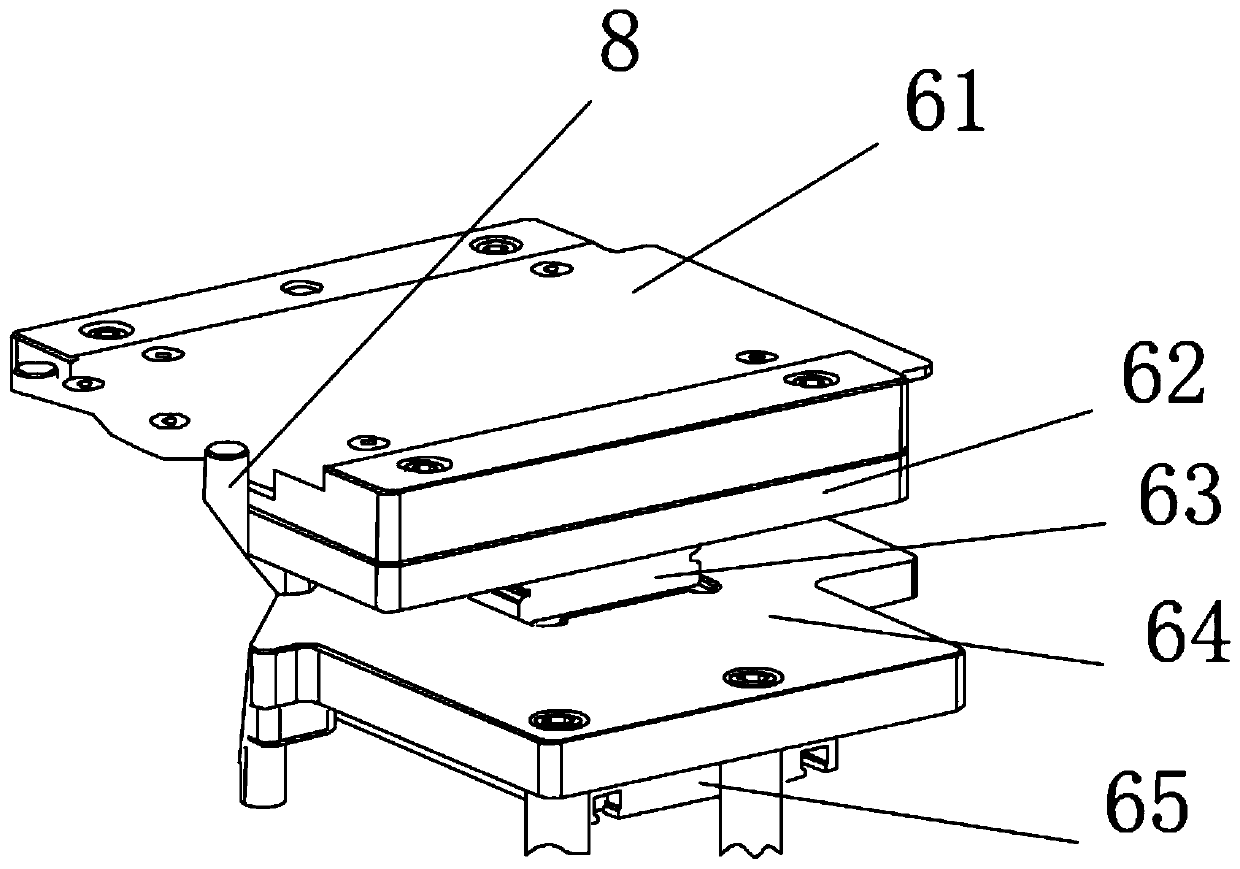

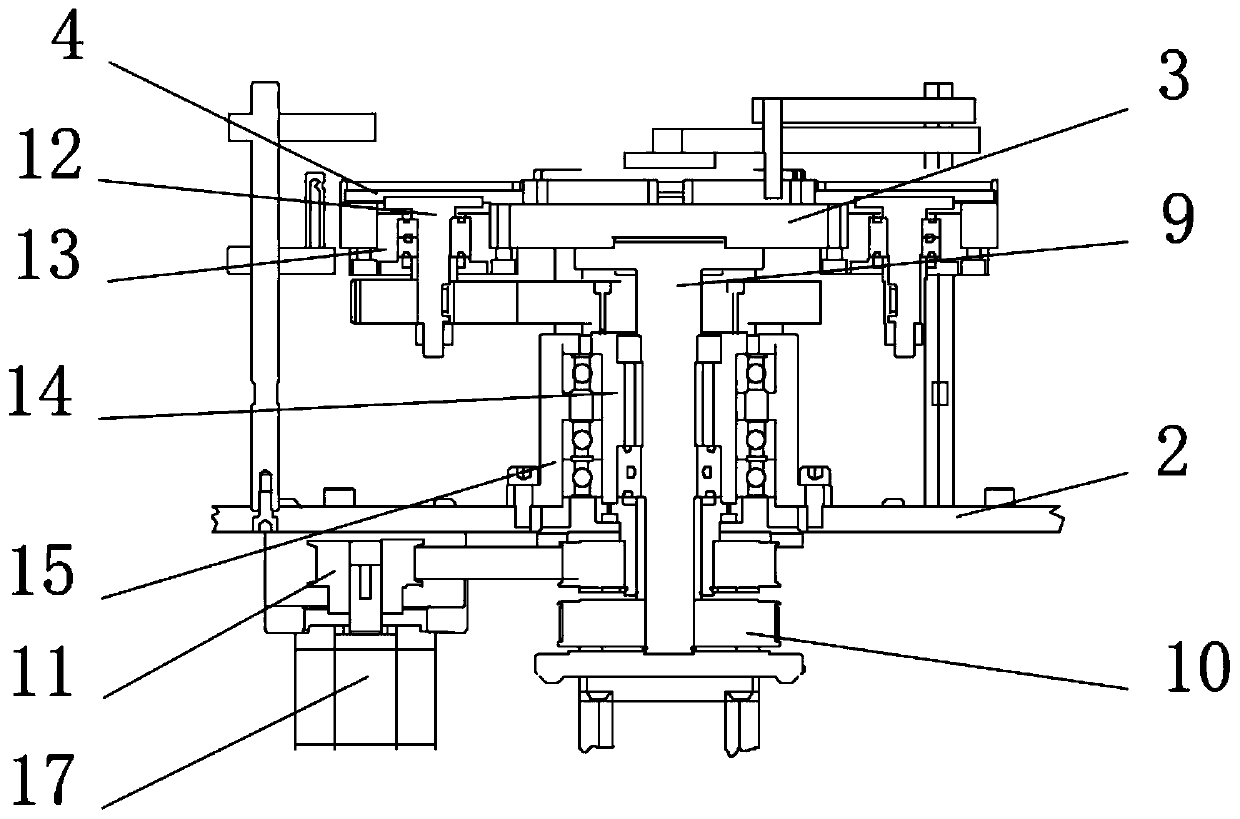

[0027] The discharge system 6 includes a rotary table outlet docking block 61, the bottom surface of the rotary table outlet docking block 61 is bolted to a docking positioning block 62, and the middle position of the bottom surface of the docking positioning block 62 is bolted to a linear slide rail 63, and the bottom of the linear slide rail 63 is provided with The guide rail mounting plate 64, the middle position of the guide rail mounting plate 64 bottom surface bolts are connected with the biaxial cylinder 65, the turntable mandrel 9 is installed at the middle position of the bottom surface of the large turntable 3, and the side surface of the turntable mandrel 9 is nested with a large gear 10, and the large turntable The gear 10 is a sixty-tooth synchronous gear, and the number of the large gear 10 is three groups, one of which is set at the top position of the turntable mandrel 9, and the other two groups are set at the bottom end of the big gear 10, and are set on the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com