An elevator car for carrying cars

A technology of elevator car and car, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve the problems of large force load, deformation of joints, and easy damage of inclined rods, etc., so as to avoid bending deformation , the effect of avoiding structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

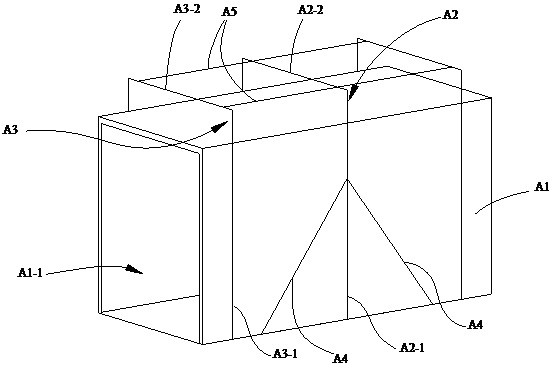

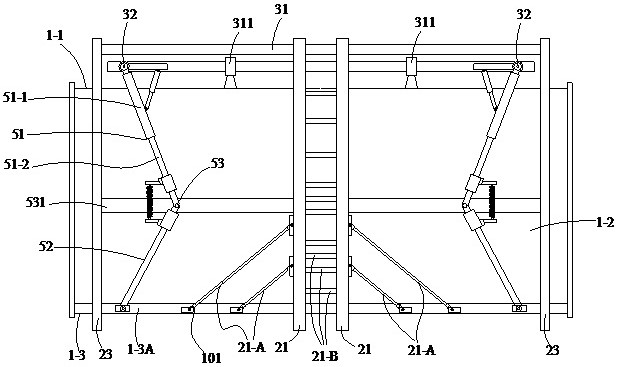

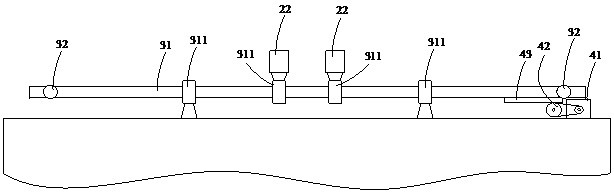

[0038] refer to figure 2 , an elevator car for carrying cars, including a car body, a main beam frame installed on the car body, and two auxiliary beam frames. The size of the car body is (2500mm-2800mm)*(6000mm-7000mm)*(2200mm -2500 mm). The car body is a single-door structure with a car door. In this implementation case, the direction in which the car door enters the car body is used as the front view direction, and the main beam frame and the two auxiliary beam frames are respectively installed on the In the middle, front and rear of the car, the main girder frame is fixed with two main vertical beams 21 on the two side panels 1-2 of the car. Since the height of the car is usually 2200mm-2500 mm, the main vertical beam The span of 21 is relatively large, so a plurality of reinforcing beams 21-B are fixedly connected between the two main vertical beams 21 of the same car side plate 1-2 to increase the structural strength. The two main vertical beams 21 and the car floor T...

Embodiment example 2

[0046] Embodiment 1 uses a cylinder and a telescopic rod to guide the rotation of the first connecting rod 51. In this embodiment, other solutions are adopted. Refer to Figure 9 , the end of the bracket 32 is fixed with a mounting frame 32-A, and the mounting frame 32-A is fixed with a section of arc-shaped slide rail 73, and the arc-shaped slide rail 73 is formed by the hinge point of the first connecting rod at the support. At the center of the circle, the upper part of the first connecting rod is provided with a sliding piece 74 slidably fitted on the arc-shaped slide rail 73 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com