Lifting device, lifting device control method and device

A lifting device and control method technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of high cost, low overall efficiency, low adjustment efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

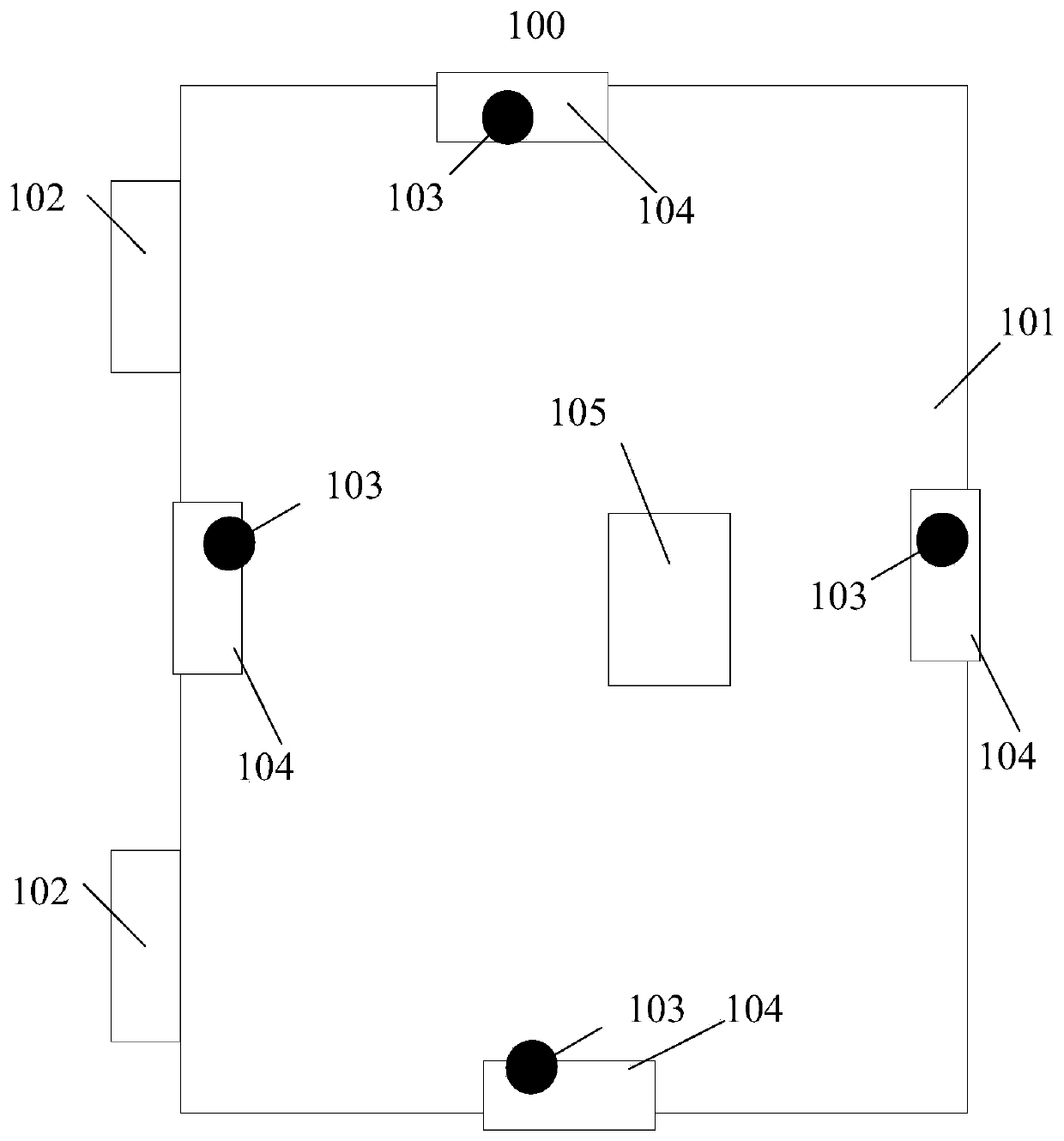

[0061] Such as figure 1 As shown, the embodiment of the present application provides a lifting device 100, including: a lifting device 101, an electronic guide plate 102, a lifting component 103, an adjustment mechanism 104, and a controller 105;

[0062] Wherein, the sling 101 includes a plurality of mounting parts of lifting parts 103 evenly distributed on the same side of the sling 101, each of the mounting parts of the lifting parts 103 is connected with an adjustment mechanism 104;

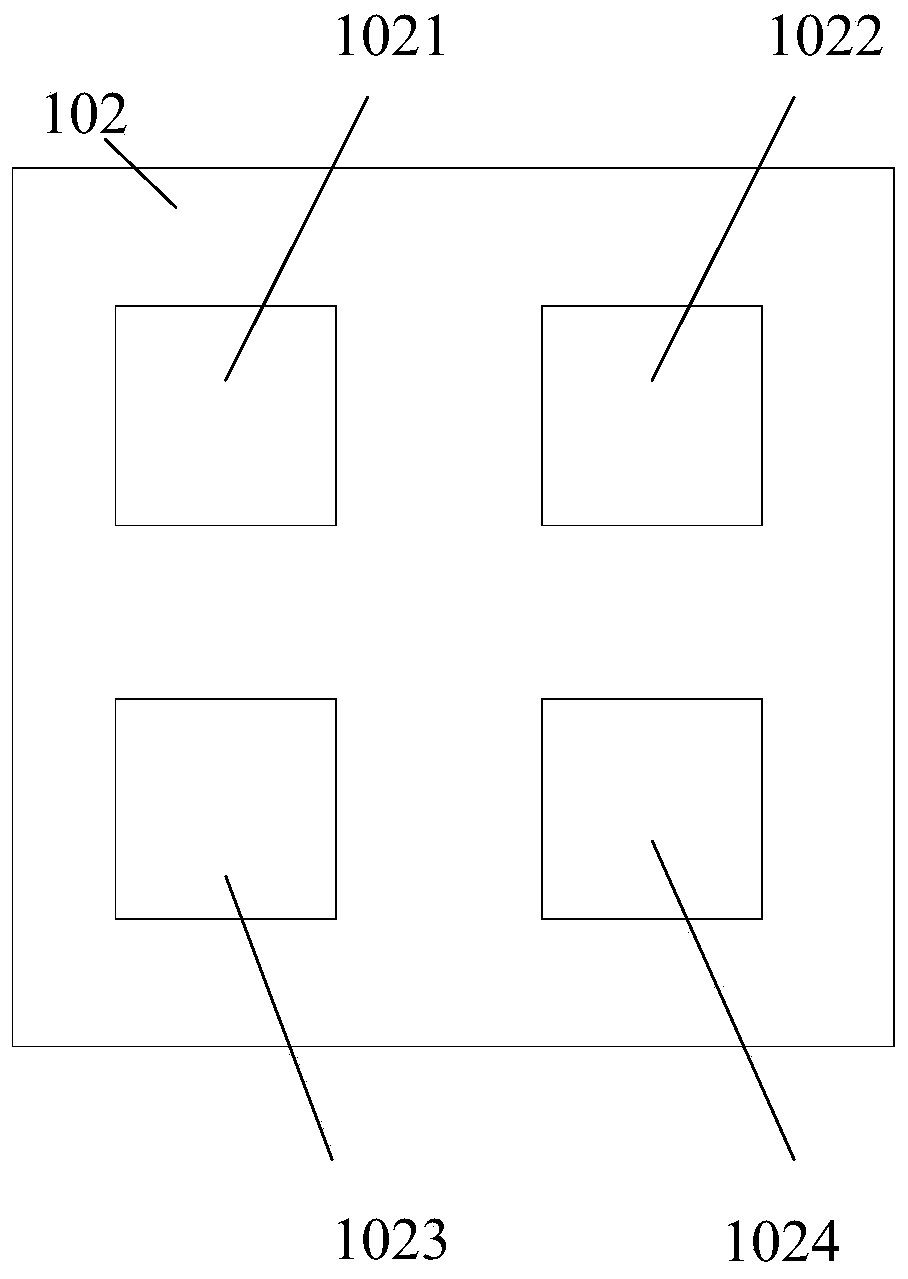

[0063] There are at least two electronic guide plates 102, and different electronic guide plates 102 are connected to different mounting parts of lifting components 103 for detecting attitude deviation information between the spreader 101 and the container;

[0064] The controller 105 is connected with the electronic guide plate 102 and used for controlling the adjustment mechanism 104 to adjust the attitude of the spreader 101 based on the attitude deviation information acquired by the elect...

Embodiment 2

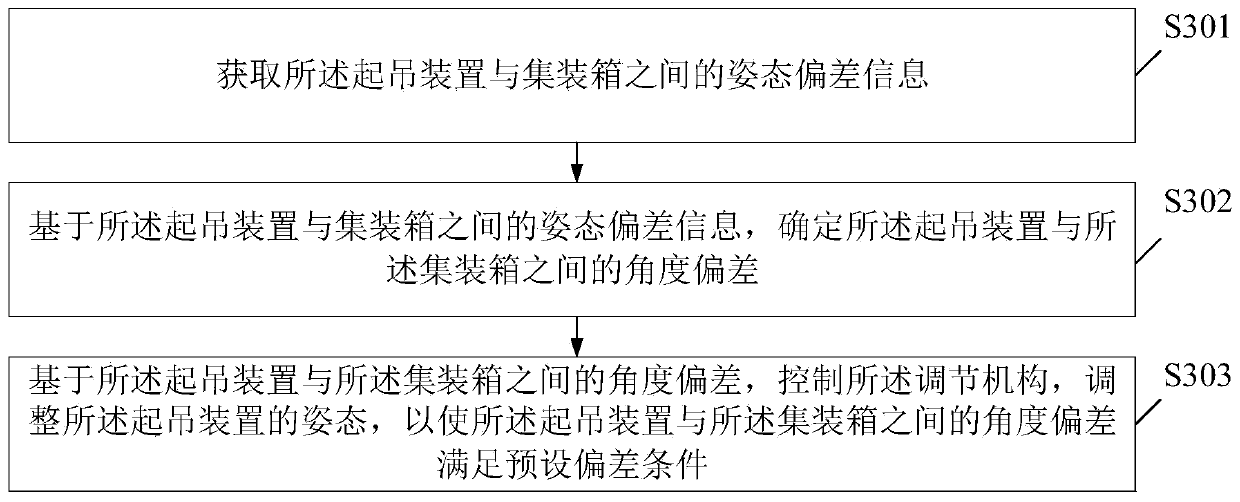

[0078] see image 3 As shown, it is a flow chart of a lifting device control method provided in Embodiment 2 of the present application. The method includes steps S301 to S303, wherein:

[0079] S301: Obtain attitude deviation information between the lifting device and the container.

[0080] S302: Based on the posture deviation information between the lifting device and the container, determine an angle deviation between the lifting device and the container.

[0081] S303: Based on the angular deviation between the lifting device and the container, control the adjustment mechanism to adjust the posture of the lifting device, so that the angular deviation between the lifting device and the container meets a preset deviation condition.

[0082] The above S301 to S303 will be described in detail below respectively.

[0083] One: In the above S301, based on the lifting device in Embodiment 1, the attitude deviation information between the lifting device and the container is ac...

Embodiment 3

[0107] refer to Figure 4 As shown, it is a schematic diagram of a lifting device control device provided in Embodiment 3 of the present application, which is used to control the above-mentioned spreader. The lifting device control device includes: an acquisition module 41, a determination module 42, and a control module 43, wherein:

[0108] The acquiring module 41 is configured to acquire attitude deviation information between the lifting device and the container;

[0109] The determination module 42 is configured to determine the angular deviation between the lifting device and the container based on the attitude deviation information between the lifting device and the container;

[0110] The control module 43 is configured to control the adjustment mechanism based on the angle deviation between the lifting device and the container, and adjust the posture of the lifting device so that the angle between the lifting device and the container The angle deviation satisfies the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com