Diffusion welding method of copper target and aluminum alloy back plate and prepared copper target assembly

A diffusion welding and aluminum alloy technology, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as the inability to meet the quality requirements for the welding joint degree of copper targets and aluminum alloy backplanes, so as to save raw material costs and expand The effect of contact area and simplification of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

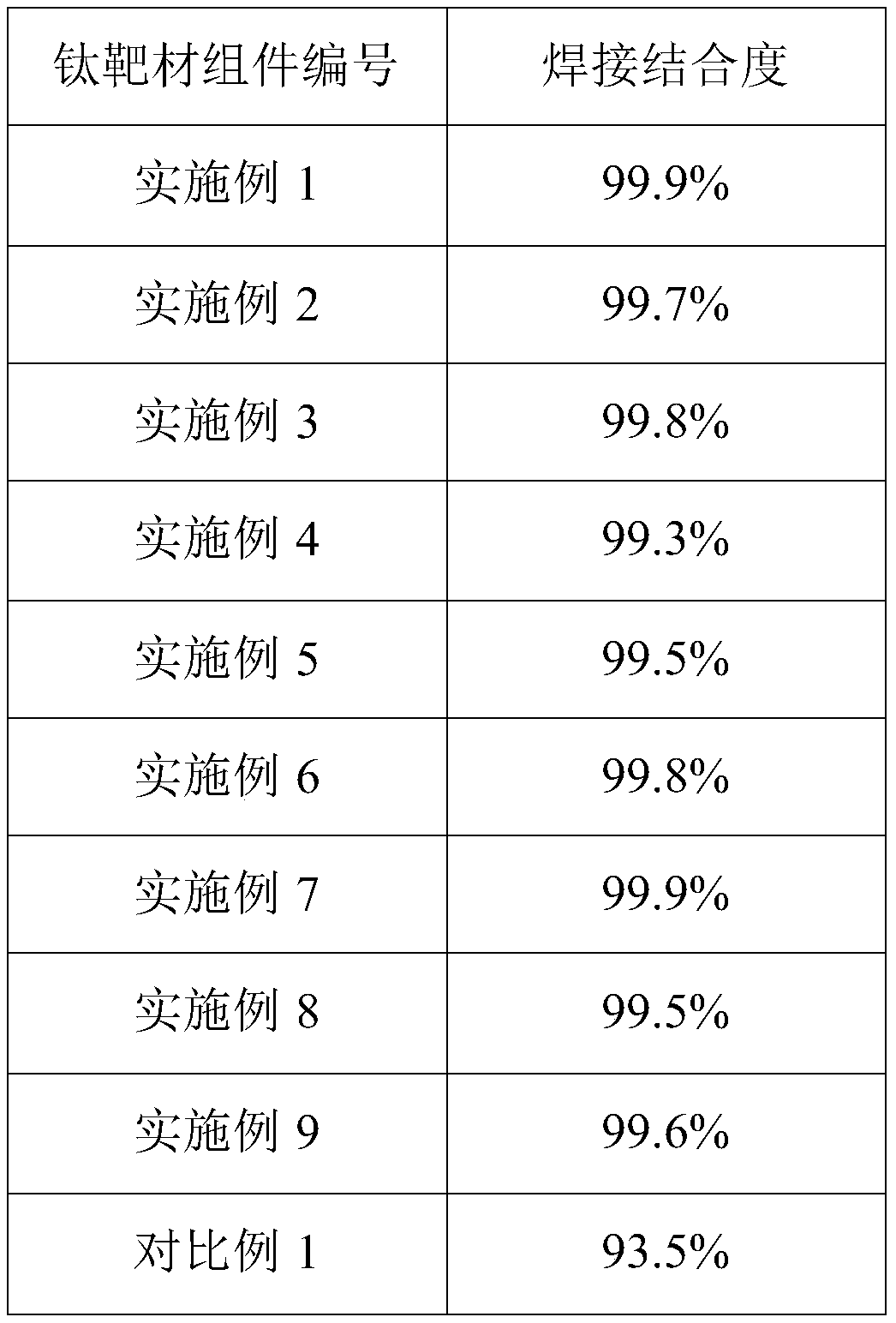

Embodiment 1

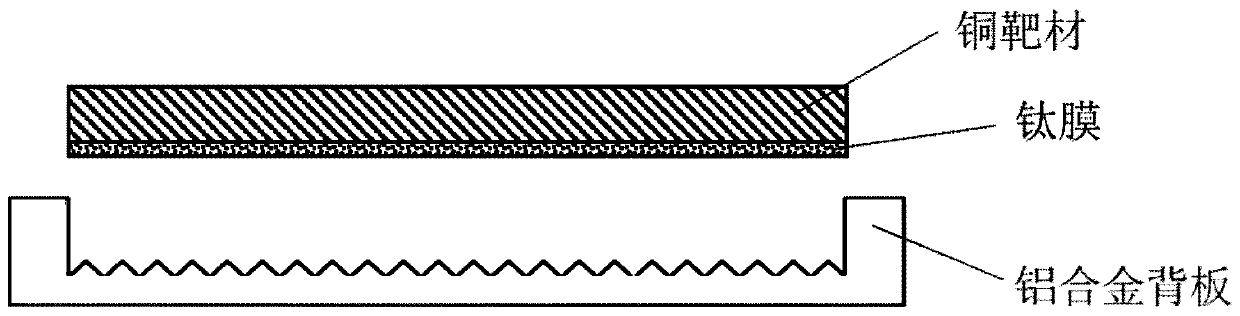

[0081] This embodiment provides a method for diffusion welding of a copper target and an aluminum alloy backplane. The diffusion welding method includes the following steps:

[0082] (1) Prepare a cylindrical copper target with a purity of 6N and a diameter of 300 mm. First, use a diamond blade to turn and smooth the welding surface of the copper target, and then clean and dry it. Ultrasonic cleaning with isopropanol cleaning solution for 10 minutes , and then vacuum-dry for 60min under the condition of vacuum degree <0.01Pa; then use the vacuum magnetron sputtering method to coat a layer of titanium film with a thickness of 5 μm on the welding surface of the copper target, the current is 20A, the bias voltage is 100V, and the temperature is 120°C for 3 hours, then cleaning and drying, in which isopropanol cleaning solution is used for ultrasonic cleaning for 10 minutes, and then vacuum drying for 40 minutes under the condition of vacuum degree <0.01Pa;

[0083]Prepare the A50...

Embodiment 2

[0088] This embodiment provides a method for diffusion welding of a copper target and an aluminum alloy backplane. Except that the thickness of the titanium film in step (1) is changed to 3 μm, other conditions are exactly the same as in Embodiment 1.

Embodiment 3

[0090] This embodiment provides a method for diffusion welding of a copper target and an aluminum alloy backplane. Except that the thickness of the titanium film in step (1) is changed to 6 μm, other conditions are exactly the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com