Combined anchoring piece and installation method for fixing heat preservation and decoration integrated plate with combined anchoring piece

A technology of anchoring parts and anchoring plates, which is applied in the directions of floors, coverings/linings, buildings, etc., can solve the problems of damage to the decorative board layer, difficult slotting operation, inconvenient installation and construction methods such as kneading and pressing, and achieves flexible application, Ease of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

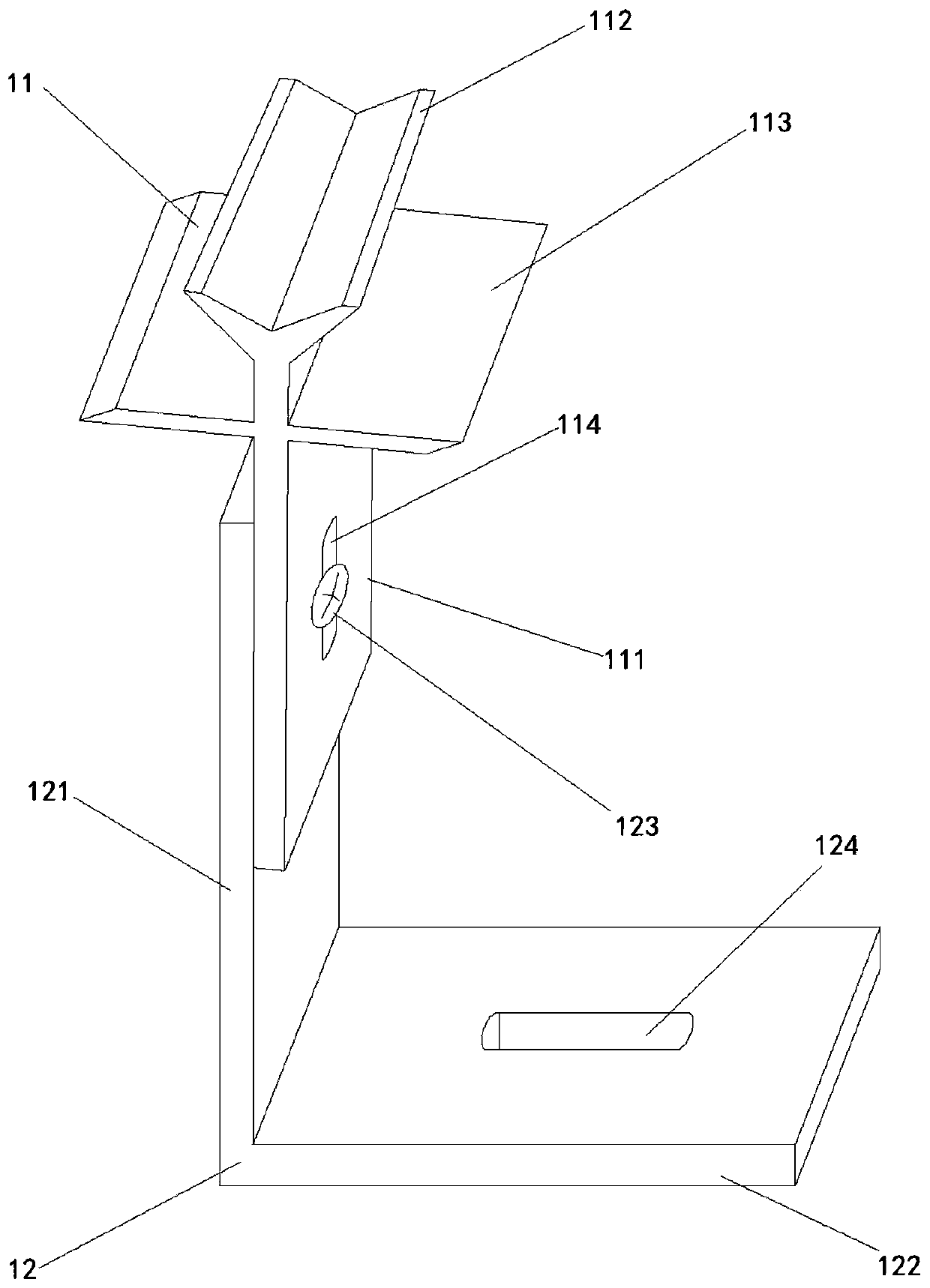

[0021] like figure 1 As shown, an embodiment of a combined anchor designed by the patent of the present invention is shown. In this embodiment, the combined anchor is assembled from two parts: the engaging part 11 and the anchoring part 12 .

[0022] The engaging part 11 includes a straight plate 111, the top of the straight plate 111 is connected with a "V"-shaped baffle 112, the middle part is vertically connected with a flat baffle 113, and the center of the lower part is opened with a through connection hole 114. The entire engaging part 11 looks like " ¥” type. Wherein, the two side plates of the “V”-shaped baffle plate 112 are respectively inclined at an angle of 45°, and the connection hole 114 is a circular rectangular hole elongated along the length direction of the straight plate 111 .

[0023] The anchoring part 12 is L-shaped as a whole, and is composed of a connecting plate 121 and an anchoring plate 122 connected vertically. The middle part of the front end of t...

Embodiment 2

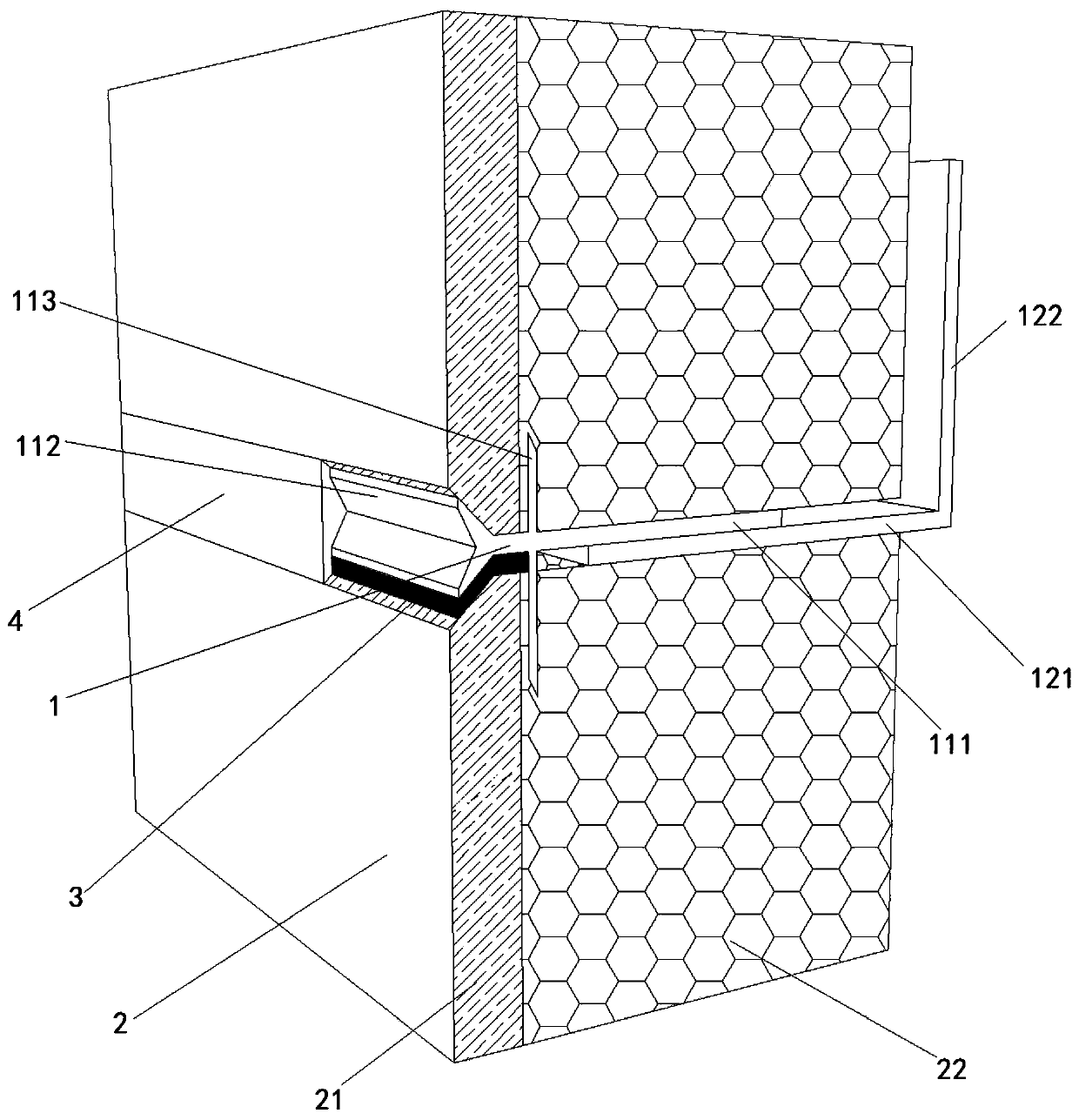

[0025] like figure 2 Shown is an embodiment of the installation structure of the thermal insulation and decoration integrated panel designed by the patent of the present invention. In this embodiment, the installation structure includes the thermal insulation and decoration integrated panel 2 and the combined anchor 1 described in Example 1. The combined anchor piece 1 is located between the upper and lower adjacent two layers of thermal insulation and decoration integrated boards 2 . The lower edge of the decorative plate layer 21 of the upper thermal insulation and decoration integrated panel 2 and the upper edge of the decorative panel layer 21 of the lower thermal insulation and decorative integrated panel 2 are respectively chamfered at 45°, and the "V" shape of the combined anchor 1 The plate 112 is engaged on the outer side of the 45° chamfer of the decorative layer 21 of the integrated thermal insulation and decoration panel 2, the flat baffle 113 is engaged in the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com