Knowledge-based fault diagnosis method for tower solar molten salt heat storage system

A technology of tower solar energy and heat storage system, which is applied in the field of knowledge-based fault diagnosis of tower solar molten salt heat storage system, and can solve problems such as diagnostic errors, freezing faults, and difficulty in temperature monitoring and calculation , to achieve the effects of reducing economic losses and potential safety hazards, improving economy and safety, and having real-time and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below in conjunction with the drawings and specific implementation examples. It should be noted that the specific implementation is only a detailed description of the present invention and should not be regarded as a limitation of the present invention.

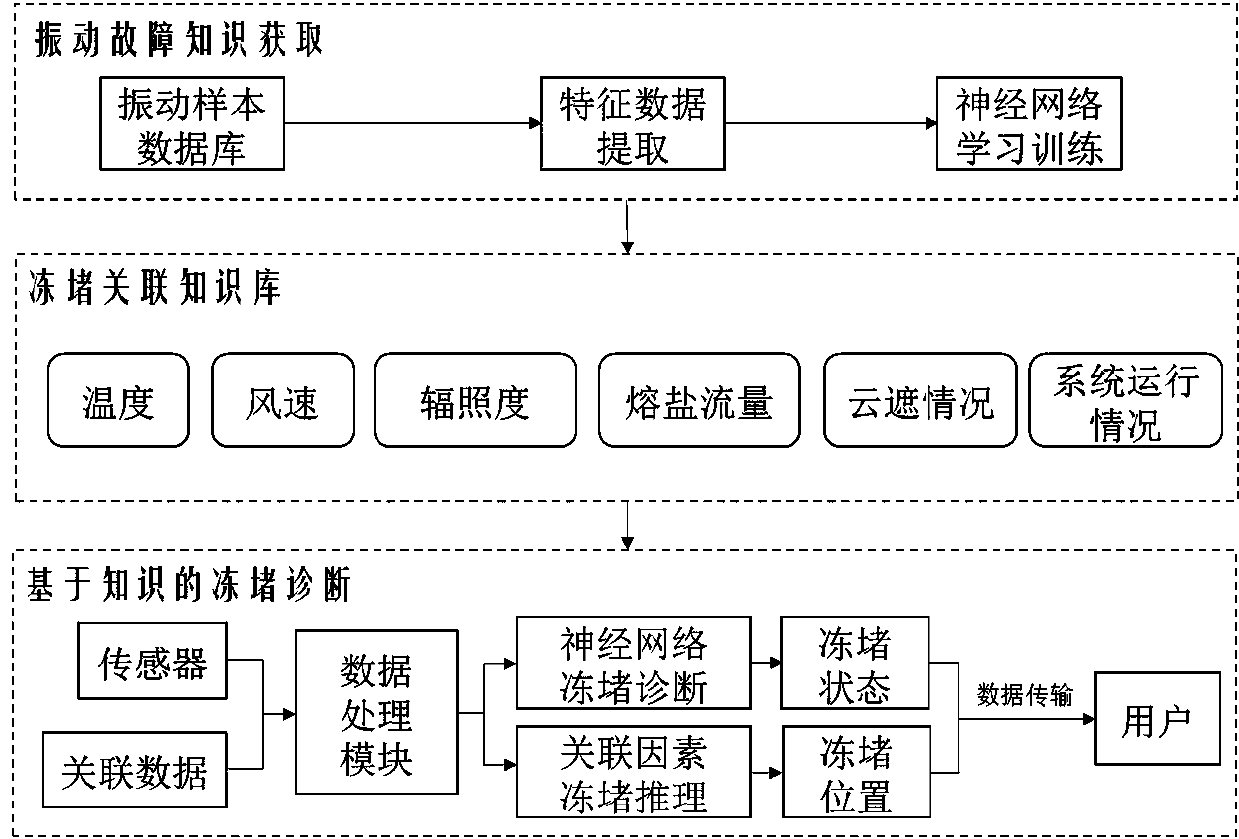

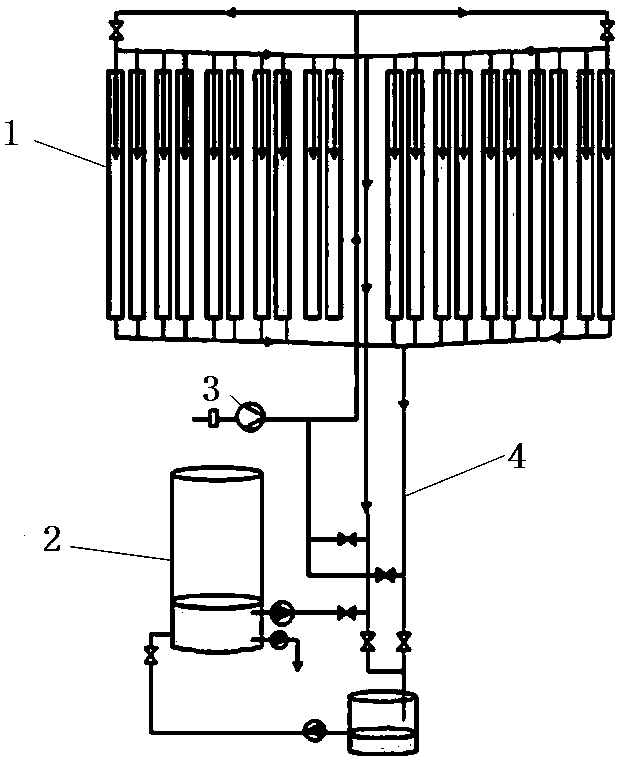

[0039] Knowledge-based fault diagnosis method for tower solar molten salt heat storage system ( figure 1 ), including the following steps:

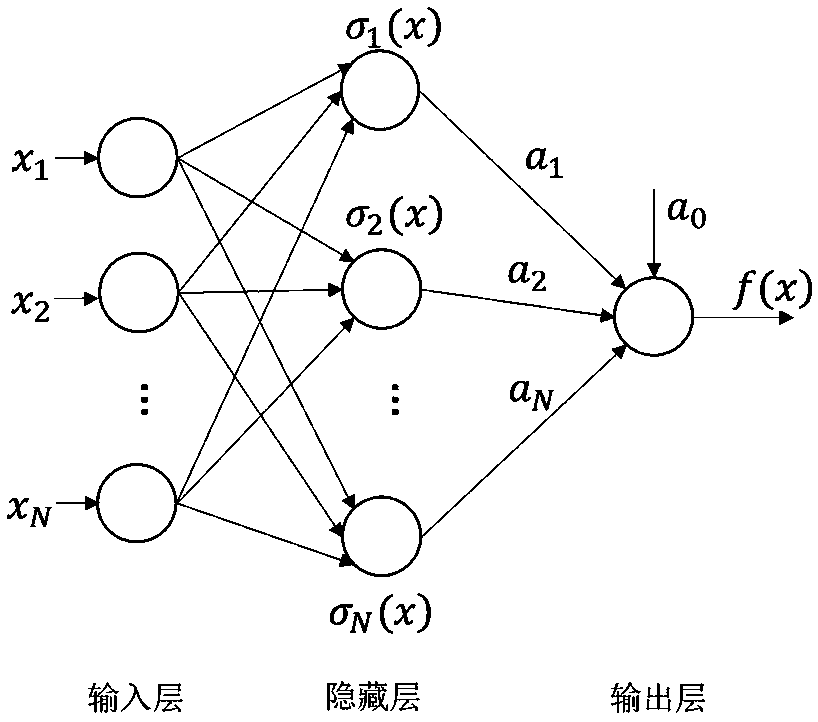

[0040] The first step is to acquire vibration fault knowledge. According to historical cases, experiments, etc., the time-domain spectrum of molten salt freezing faults is obtained and a vibration sample database is established, including freezing faults at different locations and the degree of freezing blockage, and the samples in the database are feature extracted. Neural network training is carried out on samples of degree features to achieve knowledge acquisition of vibration faults;

[0041] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com