Welding wire feeding cable

A cable and wire technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of decreased welding quality, short replacement cycle of supply cables, tearing, etc., to improve welding quality and improve space application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Next, preferred embodiments to which the present invention is applied will be described in detail with reference to the accompanying drawings. In the process of describing the embodiments to which the present invention is applied, matters that are not directly related to the technical features of the present invention or are obvious to a person having general knowledge in the technical field to which the present invention pertains and parts that can be repeatedly applied in each embodiment , detailed descriptions related to it will be omitted.

[0082] In addition, the terms used subsequently are defined in consideration of the functions in the present invention, which may change depending on the intention of the user or the applicator, custom, etc., and therefore should be explained in terms of the present invention Definitions are based on the contents of the entire specification.

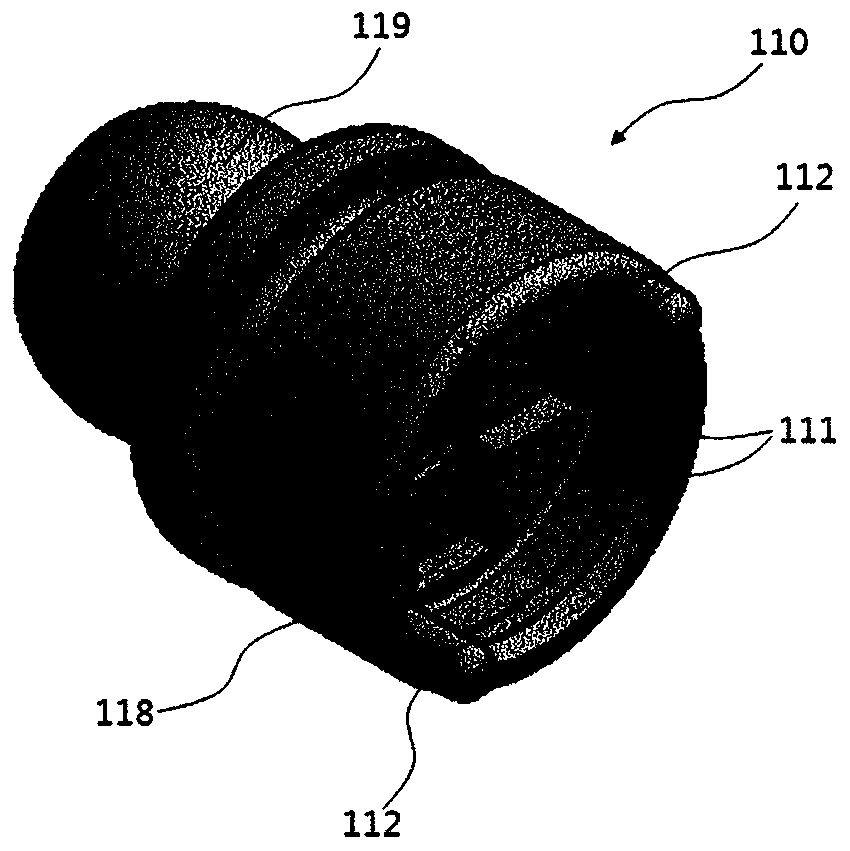

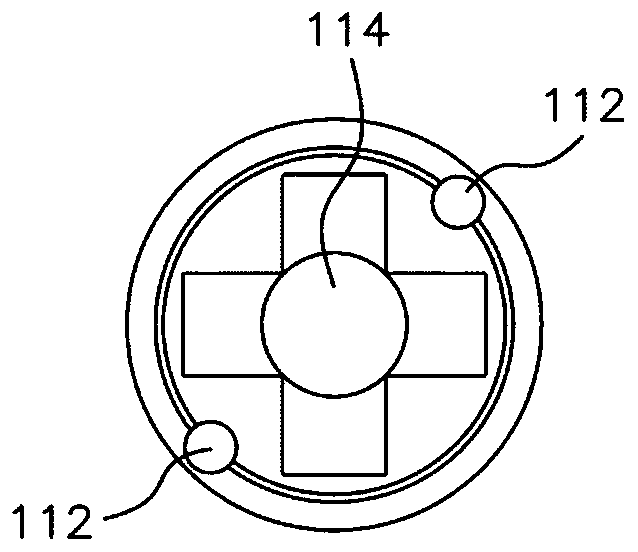

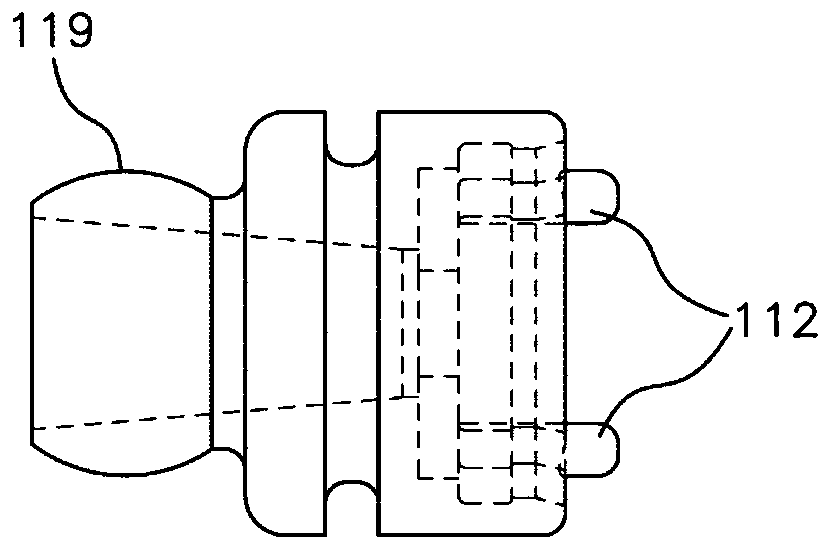

[0083] The present invention relates to a supply cable for supplying welding wire dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com