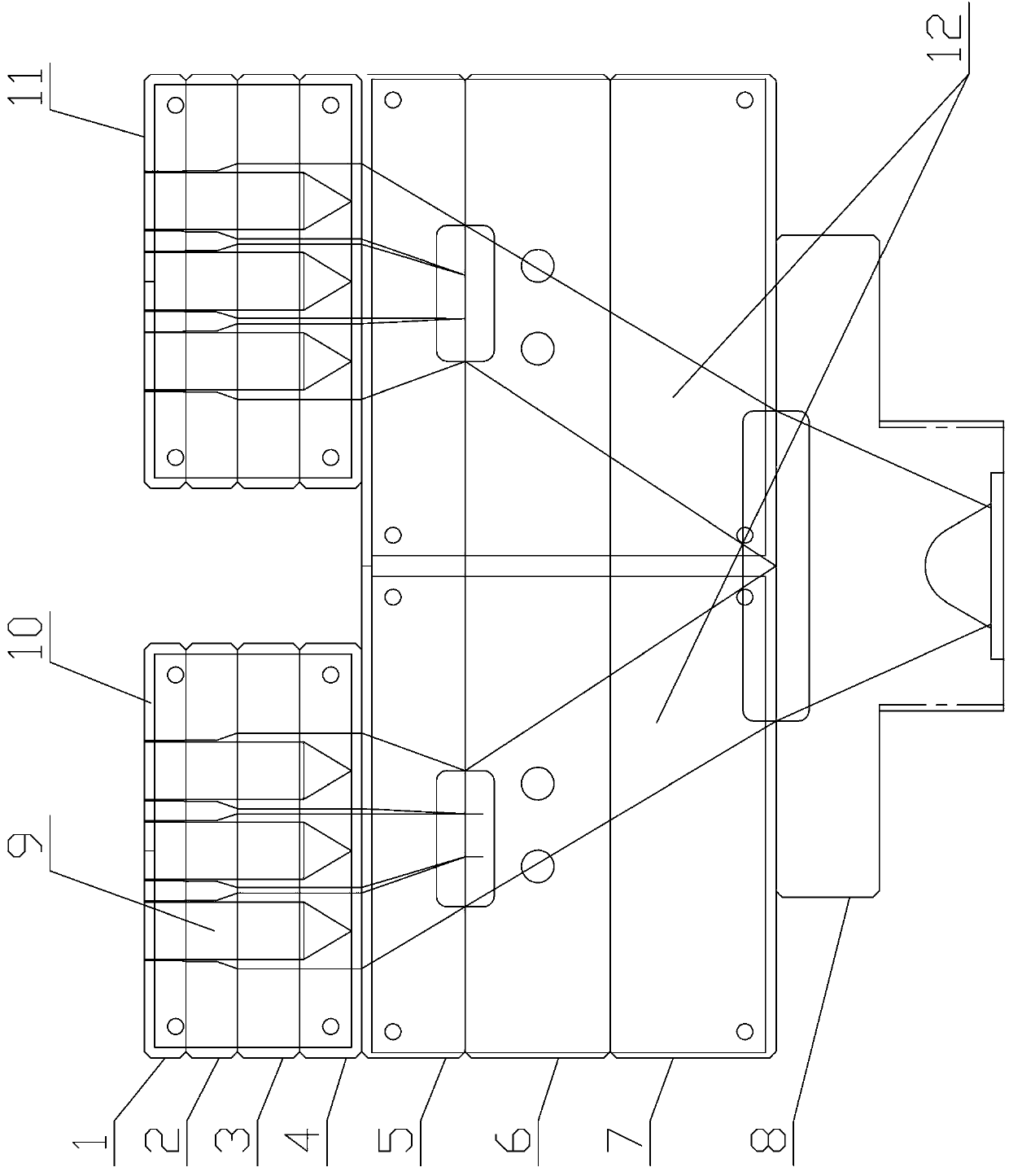

One-mold-six-cavity PVC louver strip forming mold

A molding die and molding die technology, applied in the field of extrusion die, can solve the problems of high cost, low output, low production efficiency, etc., and achieve the effects of increasing output, increasing molding output, and easy molding control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

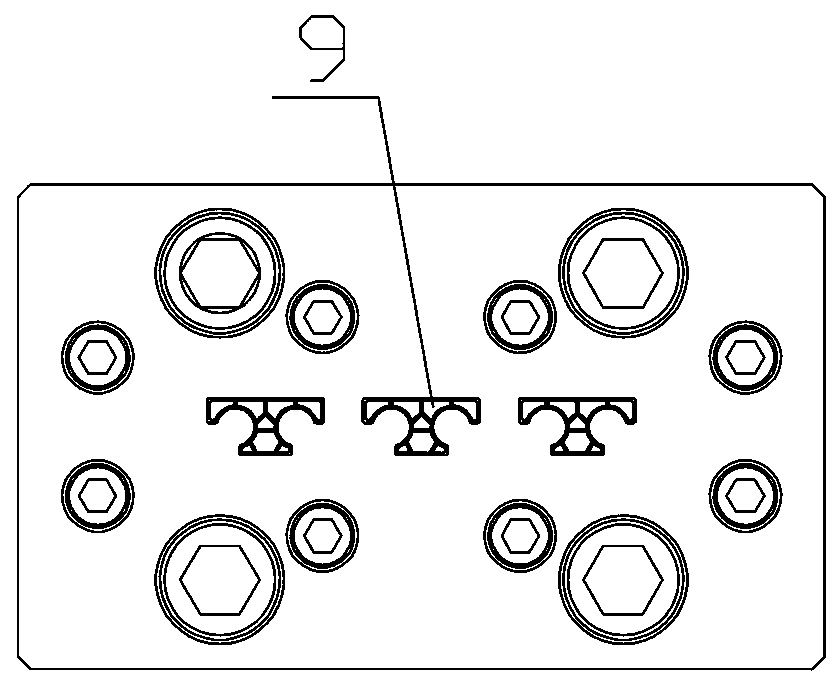

[0010] see figure 1 , figure 2 , the present invention is a one-mold six-cavity PVC louver forming mold, which sequentially includes a die 1, a die 2, a bracket plate 3, a transition plate 4, a die body transition 5, a die body transition 2 6, a die body Body transition three 7 and mold body 8, described mouth die one, mouth die two, support plate, transition plate have two groups and are forming die A10 and forming die B11 respectively, and forming die A and forming die B are all formed by mouth die one, Die 2, bracket plate and transition plate, forming die A and forming die B each contain three PVC louver forming cavities 9; sequentially from the mold body to the mold body transition 3, mold body transition 2, mold body transition One is provided with a herringbone feed flow channel 12 inside, and the two branches of the herringbone feed flow channel are respectively supplied to the forming die A and the forming die B, and each branch of the herringbone feed flow channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com