Expansion roller for road surface and step dual-purpose cleaning roller and expansion driving mechanism

A driving mechanism and cleaning roller technology, applied in the field of cleaning machinery, can solve the problem that the cleaning plane of the ladder cannot be cleaned with a flat surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

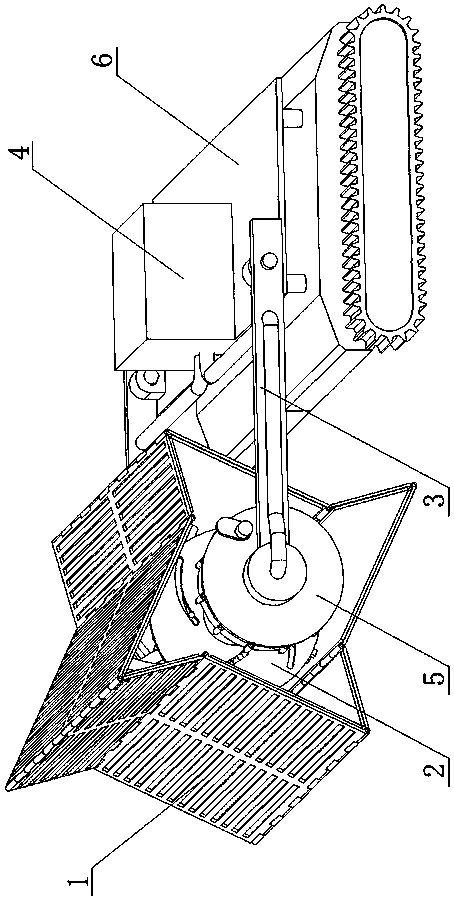

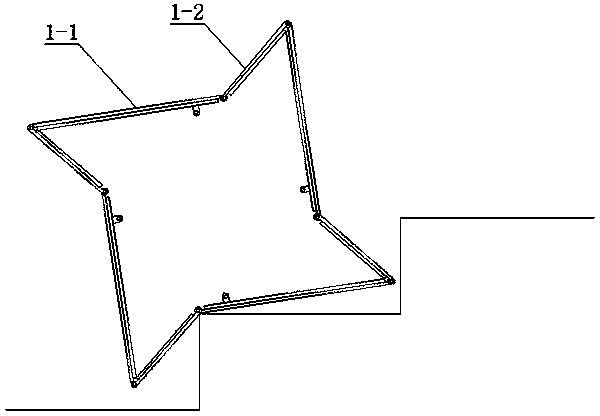

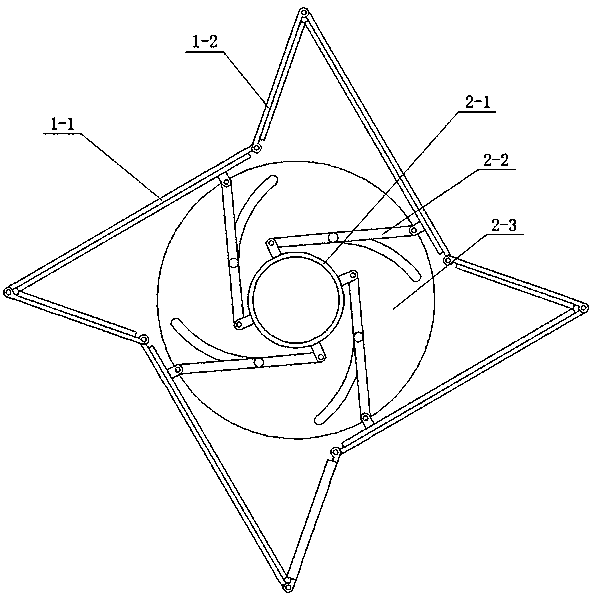

[0072] This embodiment discloses a dual-purpose cleaning roller for road surfaces and steps. The cleaning roller itself has a deformation function and can be deformed into two states. In the first state, the cleaning surface of the cleaning roller is horizontal, which is used for cleaning flat ground. In this state, the cleaning plane of the cleaning roller is bent and becomes a shape suitable for the step, which is used for cleaning the step;

[0073] combine figure 1 As shown, it includes: a roller 1, a deformation structure 2, a frame 3 and a cleaning device 4, the inside of the roller 1 is connected to the frame 3 through the deformation structure 2, and the cleaning device is connected to the roller 1;

[0074] The roller 1 is deformed by the deformation structure 2, and the roller 1 is pushed to move by the frame 3. In the first state, the roller 1 slides on the ground. In the second state, the roller 1 rolls along the steps, and the cleaning device 4 passes through The...

specific Embodiment approach 2

[0084] This embodiment discloses an arrangement of the through holes on the drum 2-1 and the main shaft 3-2 on the basis of the road surface and step dual-purpose cleaning roller disclosed in the first specific embodiment, which can reduce the Air consumption on the cleaning surface;

[0085] combine Figure 6 As shown, the docking port on the main shaft 3-2 faces downward, and the two second connecting pipes 4-3 of the step tread plate 1-1 on one surface of the drum 1 and the step side plate 1-2 are connected as one There is an interval between the connection points of the adjacent connecting pipe groups on the drum 2-1, and the interval is greater than the width of the docking port. Since the interval is greater than the width of the docking port, it is ensured that only one group of connecting pipe groups is connected at the same time. It plays a role in distributing the airflow, so that the cleaning surface used for cleaning below is connected, and the rest of the cleanin...

specific Embodiment approach 3

[0089] This embodiment discloses a cleaning machine using the cleaning roller on the basis of the road surface and step dual-purpose cleaning roller disclosed in Embodiment 1 or 2. The cleaning machine can move on flat ground and steps, and pull the cleaning roller to clean up;

[0090] combine figure 1 and Figure 7 As shown, the cleaning roller is pushed by the cleaning vehicle 6, and the cleaning vehicle 6 includes: a vehicle body 6-1, a crawler wheel 6-2, a connecting platform 6-3 and a hinged seat 6-4, and the vehicle body 6-1 The two sides of the car body 6-1 are provided with track wheels 6-2, the length of the track wheels 6-2 is greater than the step spacing, the upper end of the car body 6-1 is provided with a connecting platform 6-3, and the cleaning device 4 of the cleaning roller is arranged on On the connecting platform 6-3, the front end of the connecting platform 6-3 is provided with a hinged seat 6-4, and the connecting seat 6-4 is connected with the frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com