Window blind blade and method for preparing window blind blade

A technology of blades and curtains, applied in the field of venetian blind blades and the preparation of said venetian blind blades, which can solve the problems of rainwater seeping into a room, the relative height of venetian blind blades cannot be adjusted, and affecting the actual experience of users, so as to reduce gaps, tight fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

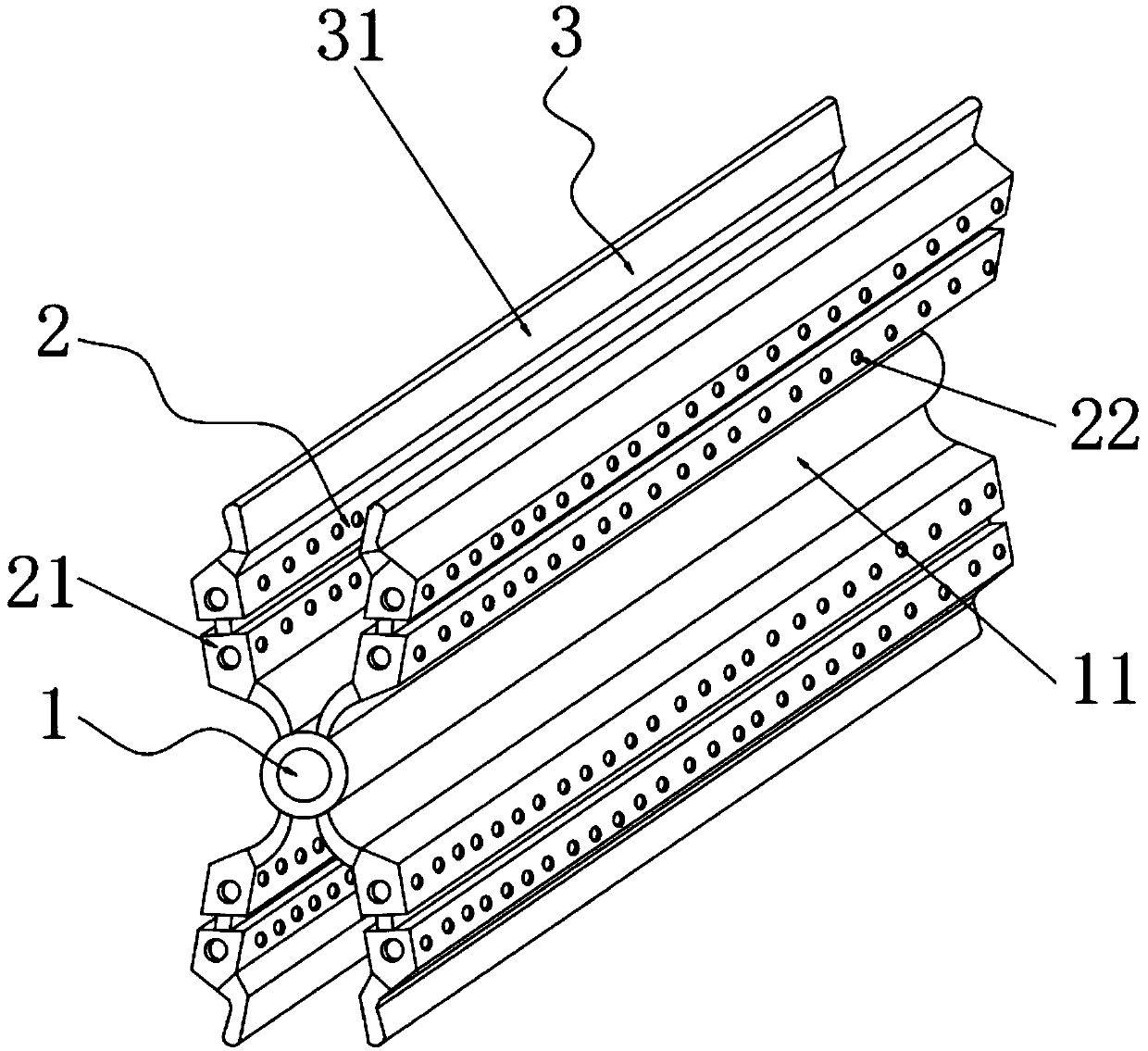

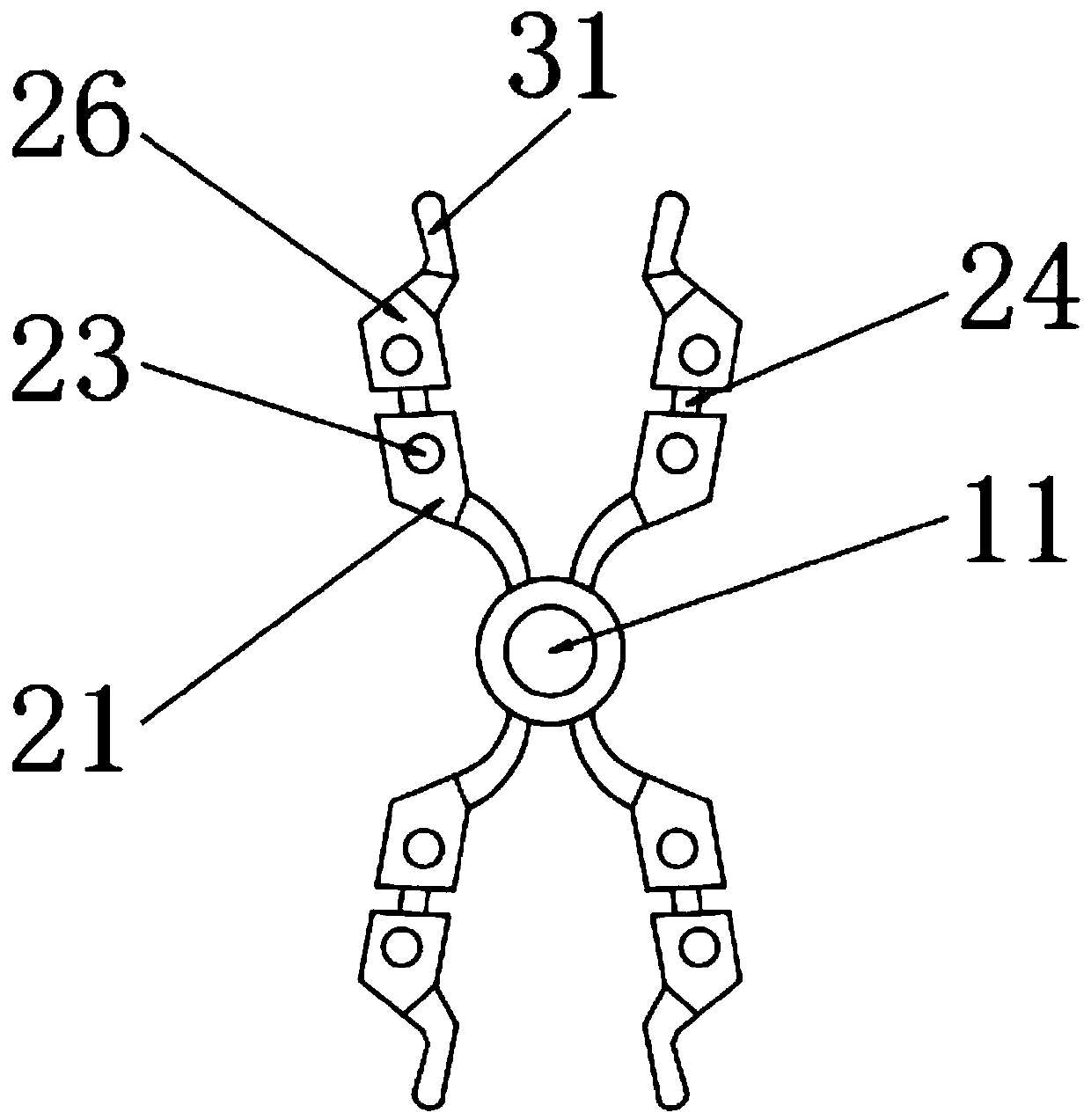

[0035] see Figure 1-2 , the present invention provides a technical solution: a blind blade, including a connecting assembly 1, the connecting assembly 1 is mainly composed of a connecting pipe 11, and the connecting pipe 11 is a hollow cylinder, and also includes a driving assembly 2 located on the connecting assembly 1 and a seal assembly 3 located on the drive assembly 2;

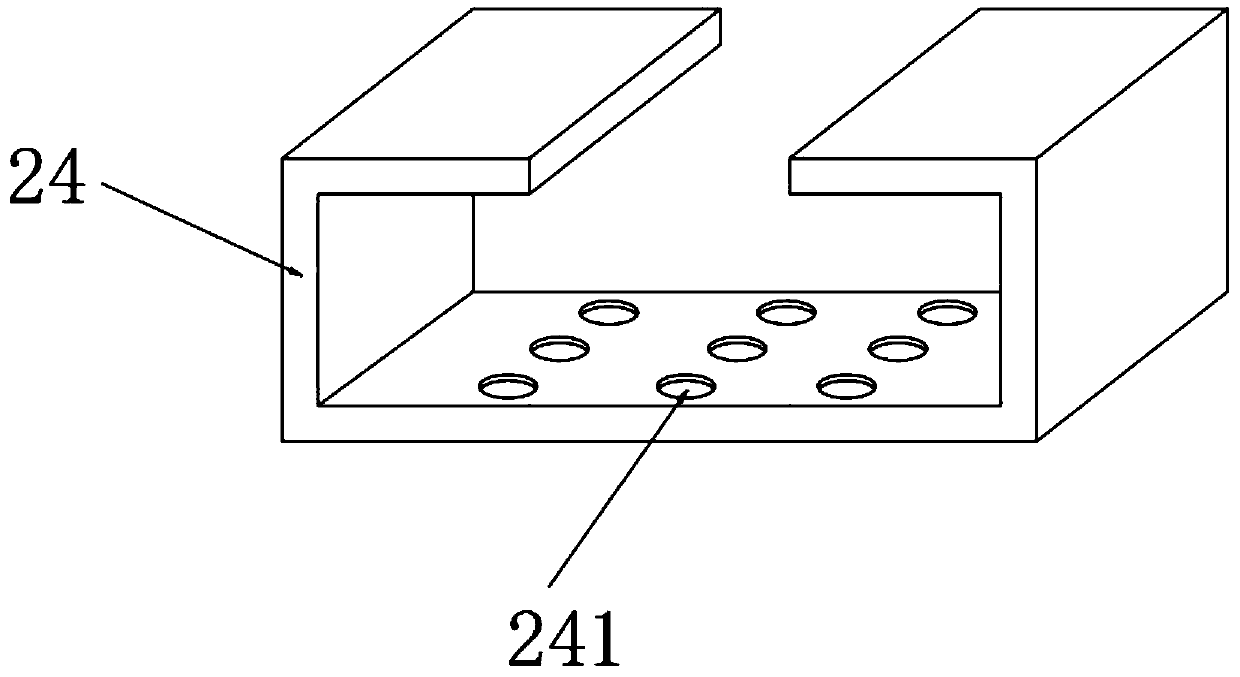

[0036] The drive assembly 2 includes a first blade 21, a connecting piece 24 and a slider 25. The first blade 21 is located on the outer wall of the connecting pipe 11 and is welded and fixed to the connecting pipe 11. The front surface and the rear surface of the first blade 21 are opened There is a powder medicine hole 22, and the side of the first blade 21 is provided with a drug injection hole 23, and the side of the first blade 21 far away from the connecting pipe 11 is welded and fixed with a connecting piece 24, and the outer surface of the connecting piece 24 is provided with a limiting hole 241,...

Embodiment 2

[0043] see Figure 3-7 , the sealing assembly 3 includes a first sealing plate 31, a second connecting plate 32 and a second sealing plate 33, the first sealing plate 31 is located on the side of the second blade 26 away from the slider 25, the first sealing plate 31 and the second blade 26 Adhesively fixed, the side of the first sealing plate 31 away from the second blade 26 is glued and fixed with the second connecting plate 32, the side of the second connecting plate 32 away from the first sealing plate 31 is fixedly provided with a second return spring 321, the second The return spring 321 is fixed with the third connecting plate 322 on the side away from the second connecting plate 32 , and the second sealing plate 33 is adhesively fixed on the side of the second sealing plate 33 away from the third connecting plate 322 .

[0044] In this embodiment: the first blade 21 is provided with a connecting piece 24, and the second blade 26 is provided with a first connecting plat...

Embodiment 3

[0054] The present invention also provides a method for preparing the blind blade, comprising the steps of:

[0055] S1: Place the connecting pipe on the workbench, and extrude the pipe into the first blade and the second blade through the mold;

[0056] S2: fixing the first blade to the connecting pipe by welding, and welding the connecting piece on the first blade;

[0057] S3: Fix the first connecting plate to the second blade by welding, engage the connecting piece through the slider, and engage the limit hole on the connecting piece through the button on the slider, and then complete the first blade and the second blade. fixation of blades;

[0058] S4: bonding the first sealing plate to the second blade, and connecting the first sealing plate and the second sealing plate through the second connecting plate, the second return spring and the third connecting plate; that is, the assembly of the blade is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com