Damping and denoising device for electromechanical equipment

A technology of electromechanical equipment and sets, applied in mechanical equipment, springs/shock absorbers, supporting machines, etc., can solve the problems of poor shock absorption and not comprehensive shock absorption, and achieve good shock absorption and comprehensive shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

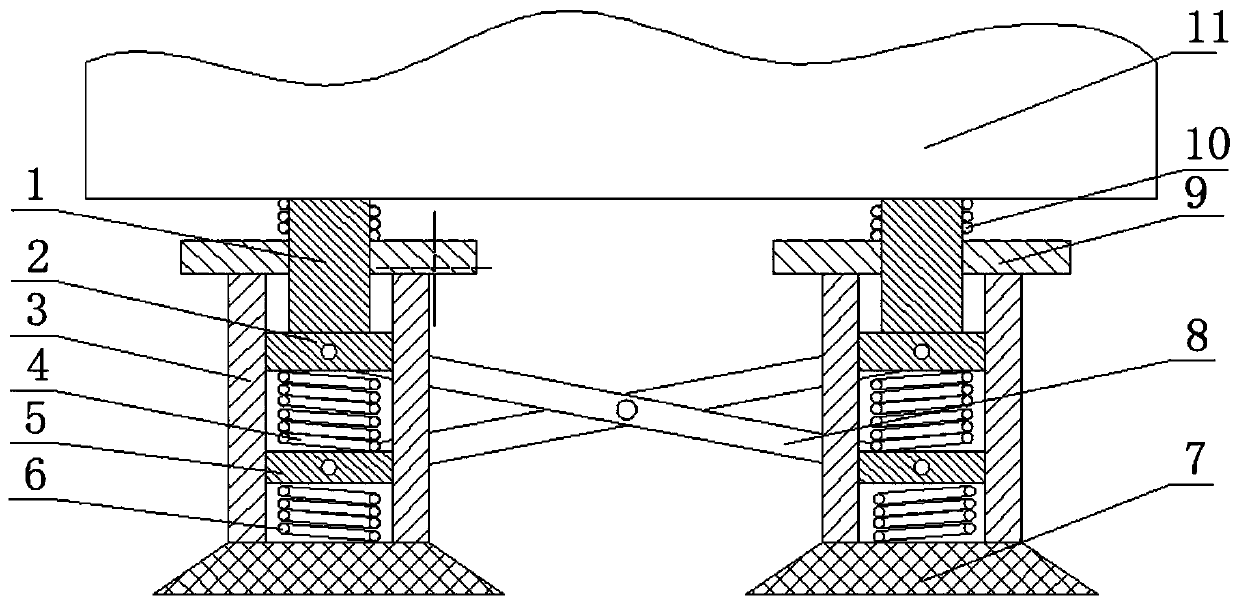

[0018] Such as figure 1 As shown, the embodiment of the present invention provides a shock-absorbing and noise-removing device for electromechanical equipment, including a buffer structure provided on the support leg 1 of the electromechanical device 11, and two connecting rods 8 arranged crosswise are connected between each two buffer structures .

[0019] The buffer structure includes a slider 12 provided at the bottom of the support leg 1, and a vertical sleeve 3 is set outside the slider 12. The bottom of the sleeve 3 is provided with a base 7, and the top of the sleeve 3 is provided with a cover plate 9. The cover plate 9 Set on support leg 1.

[0020] Slots are provided on the sleeve 3, and the slots are opened along the axial direction of the sleeve 3; a slider II5 and a slider I2 are sequentially slid in the sleeve 3, and an elastic member I4 is connected between the slider I2 and the slider II5. An elastic member II6 is connected between the slider II5 and the base ...

Embodiment 2

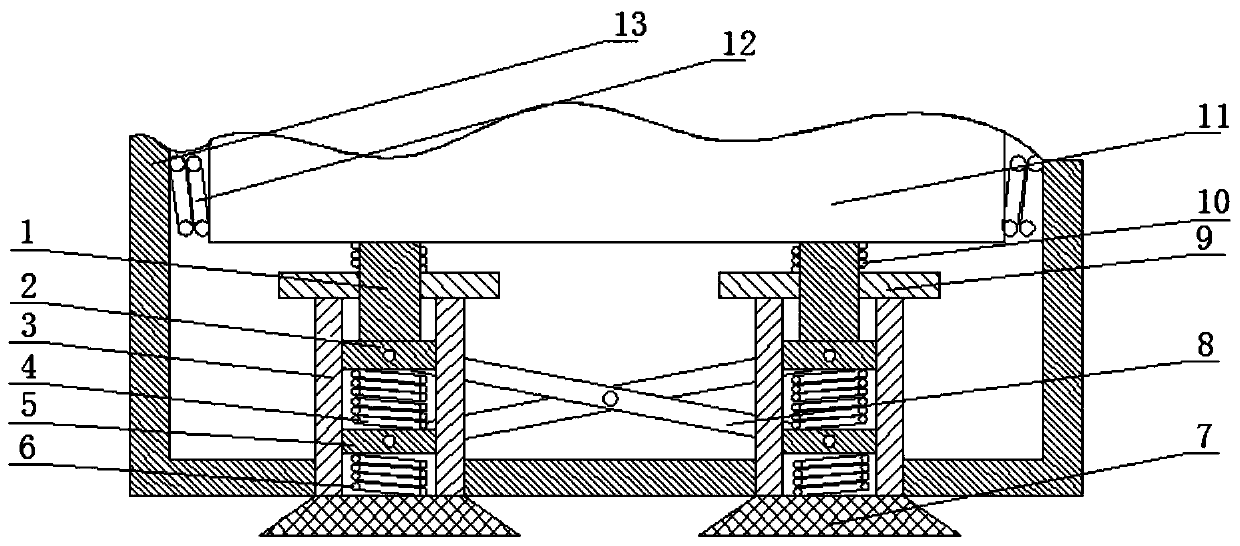

[0025] On the basis of Embodiment 1, in order to slow down the vibration of the electromechanical equipment 11 in the horizontal direction, the buffer structure is arranged in the box body 13, and the sleeve 3 of the buffer structure passes through the inner bottom surface of the box body 13 and is connected to the base 7, and the box body Between the inner wall of 13 and the electromechanical equipment 11, a plurality of elastic parts IV12 are evenly distributed.

[0026] In summary, the embodiment of the present invention provides a shock-absorbing and noise-removing device for electromechanical equipment. When the electromechanical equipment is working, the slider I has a tendency to move up and down along the sleeve, and the vibration energy generated by the electromechanical equipment is controlled by the elastic member I. The first absorption, while the connecting rod rotates, another connecting rod pushes the slider II upward to make the elastic part I compress again to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com