A pressure gauge for a high pressure vessel

A high-pressure container and pressure gauge technology, which is applied in piston-type fluid pressure measurement, fluid pressure measurement, instruments, etc., can solve the problems of reduced measurement accuracy in low-pressure areas and less effective measurement range of pressure gauges, and achieves easy calibration, Large deformation capacity, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The standard parts used in the present invention can be purchased from the market, and the shaped parts can be customized according to the description of the book and the description of the drawings, and the specific connection of each part uses prior art bolts, rivets, welding. General means such as paste, etc., this is no longer detailed.

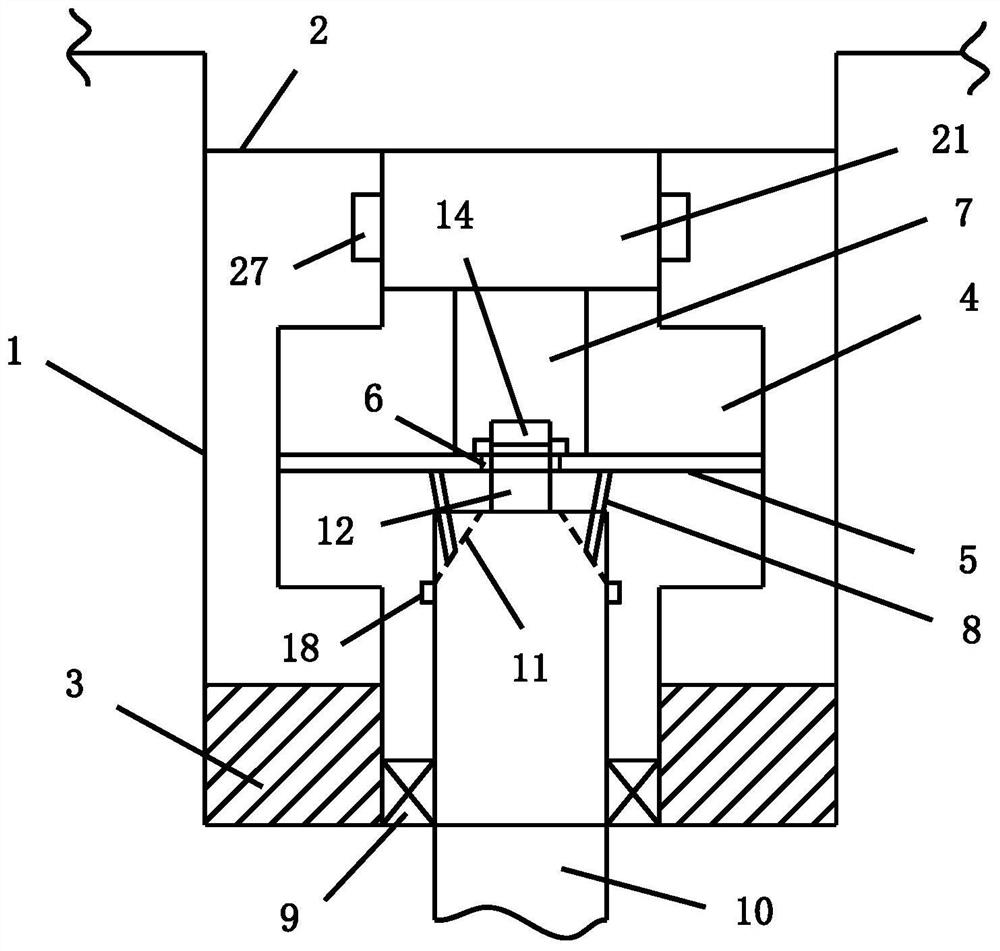

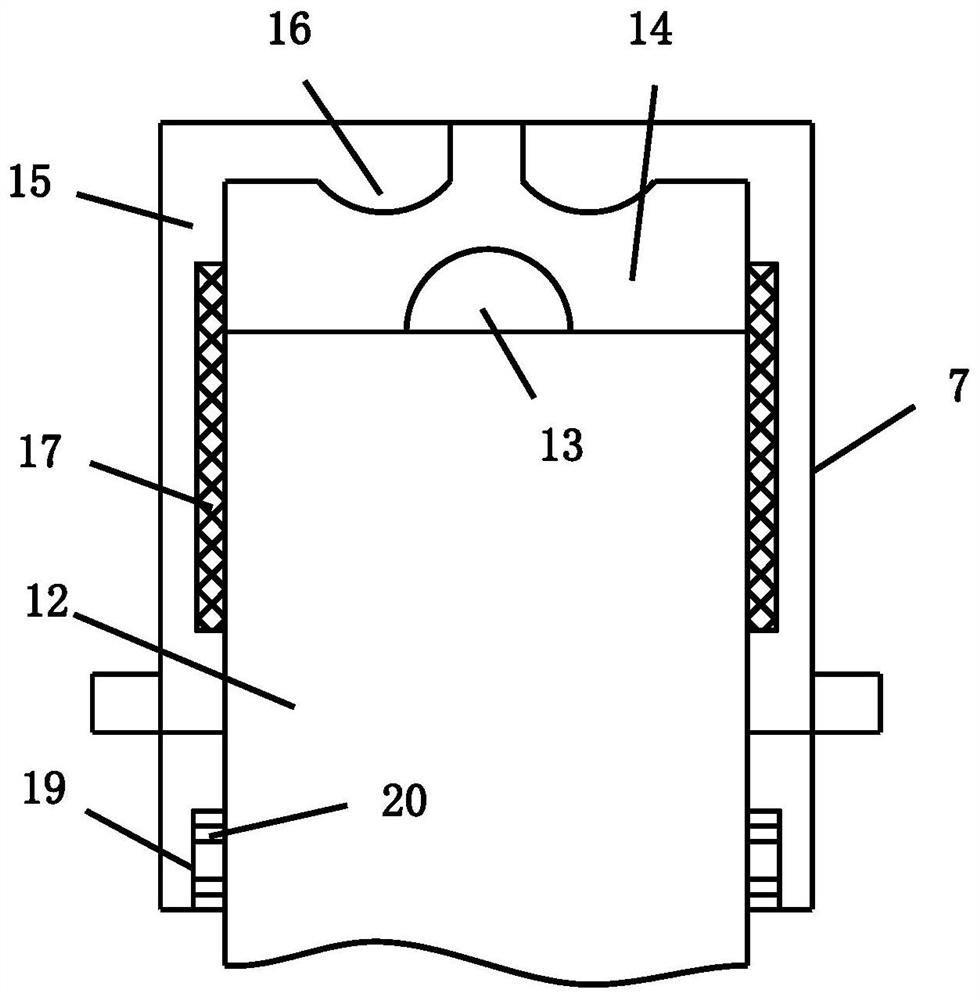

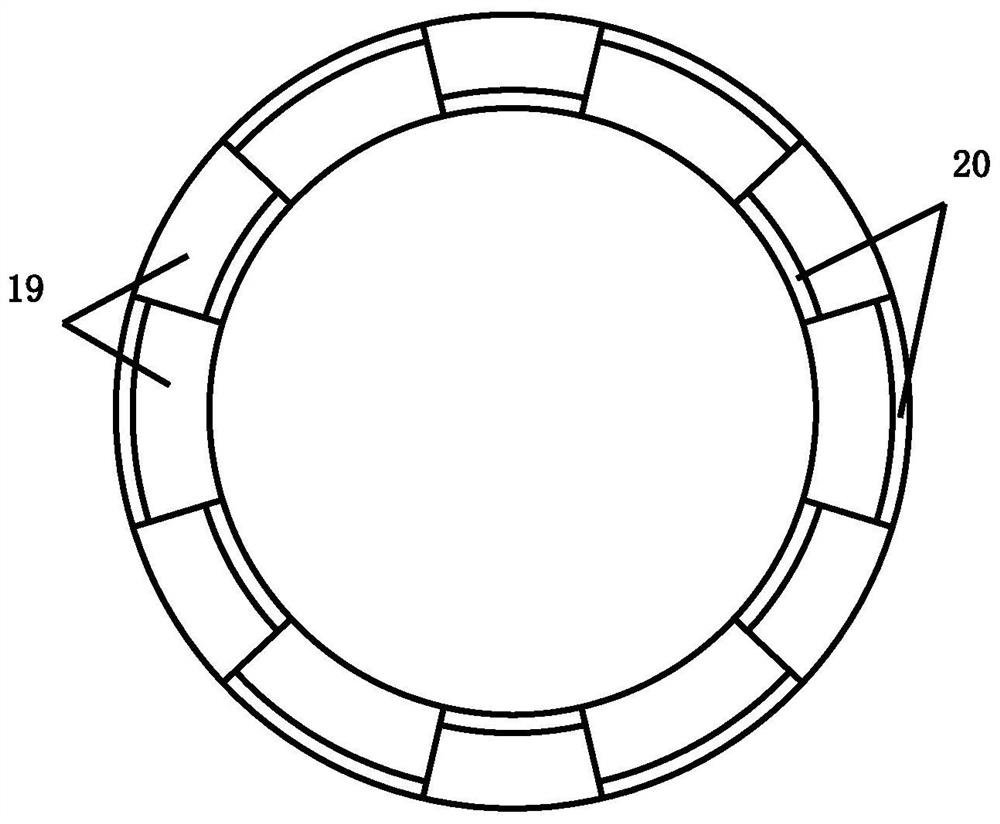

[0017] Refer Figure 1-4 , A particular embodiment of the present invention comprises a housing 1, a top outer casing 1 is connected to the header 2, a bottom of the outer housing 1 is provided with a threaded portion 3, there is provided a diaphragm chamber within the housing body 4, the diaphragm chamber 4 is fixed to the inner separator 5, the diaphragm 5 is provided with a central through hole 6, the top edge of the through hole 6 side is fixed to the lifting of the core 7, the core 7 lifting the outer jacket 21 is mounted a lifting, lifting the jacket 21 and the header 2 connecting bottom edge of the through hole 6 is fixed to a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com