Civil engineering structure anti-seismic test device

A technology of civil engineering structure and seismic test, applied in the direction of machine/structural component test, measuring device, vibration test, etc., to achieve the effect of ensuring accuracy, convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

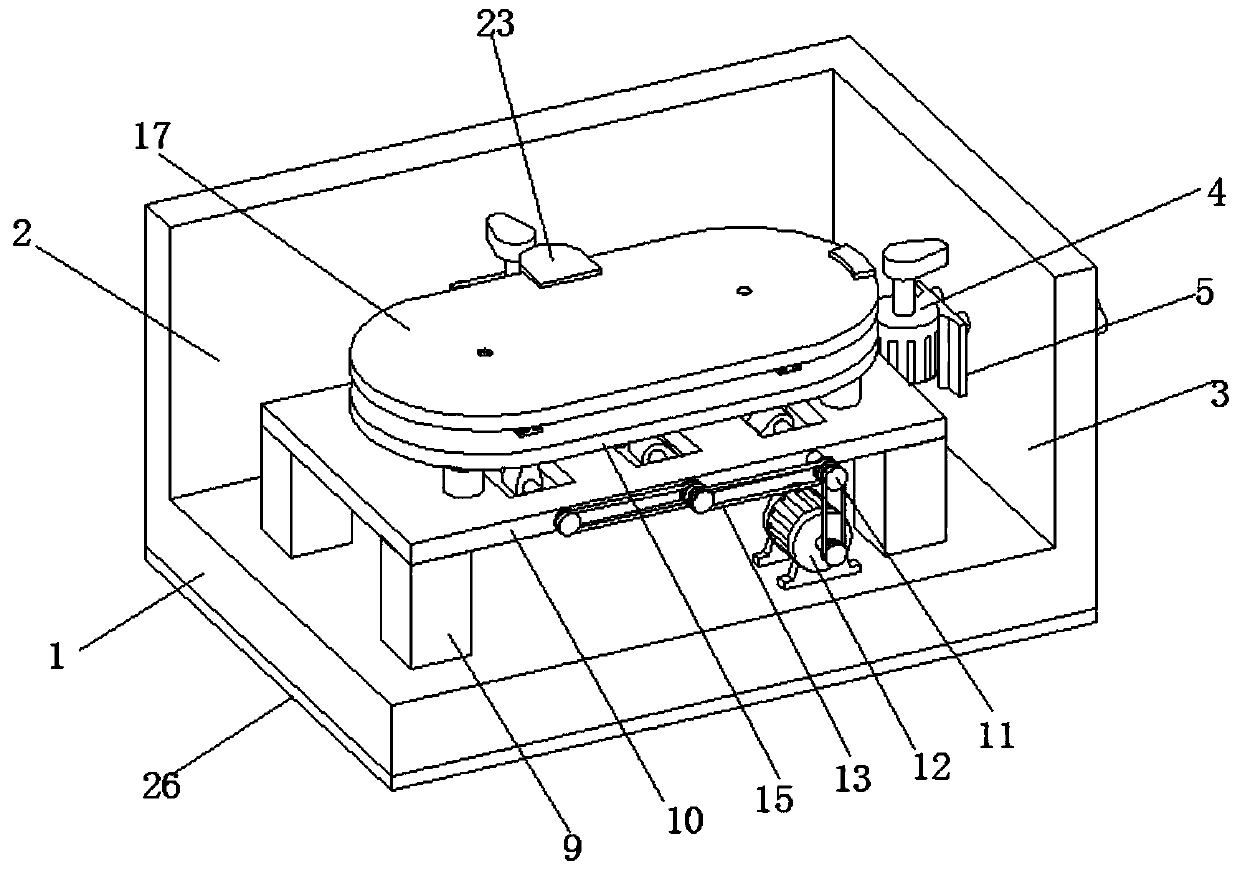

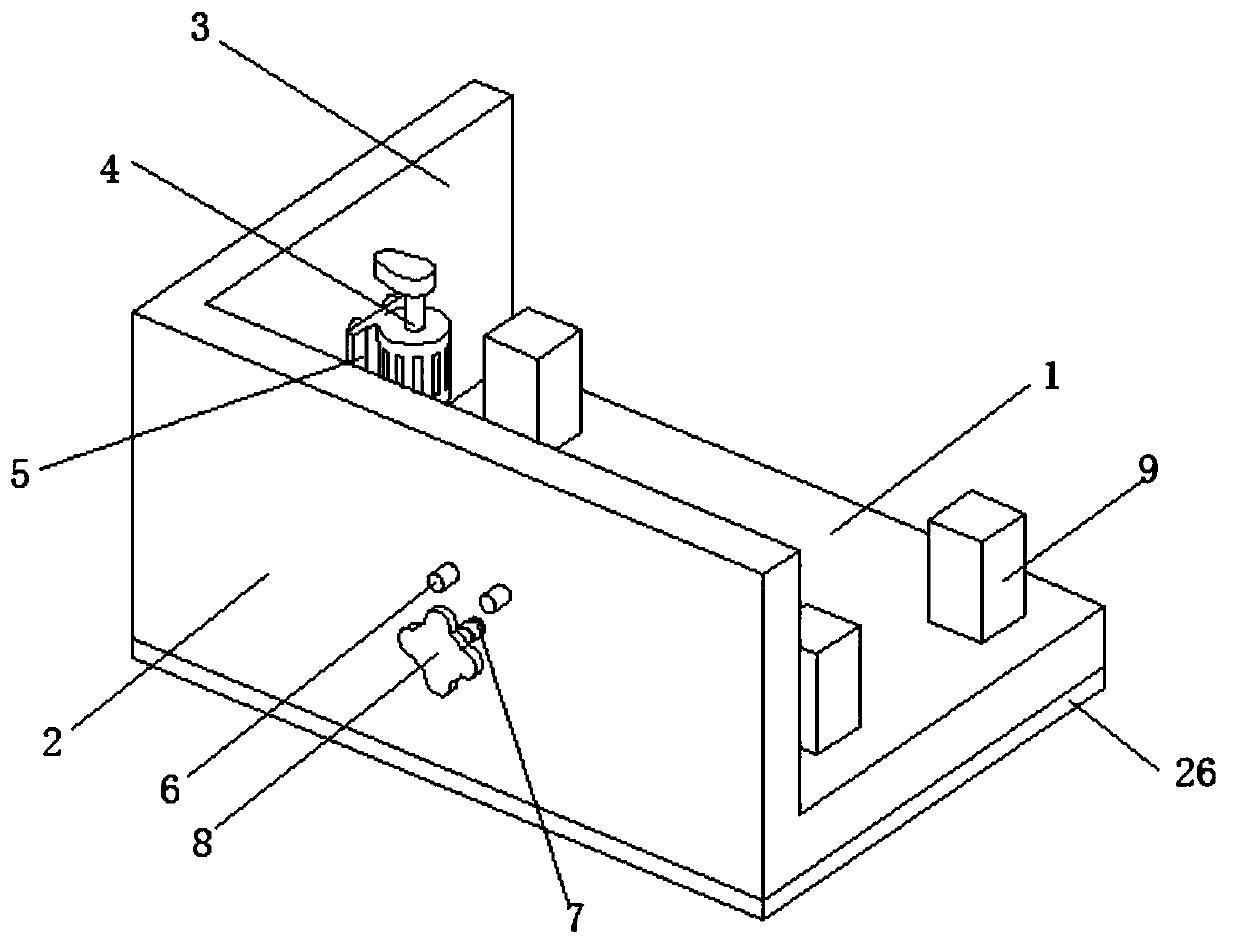

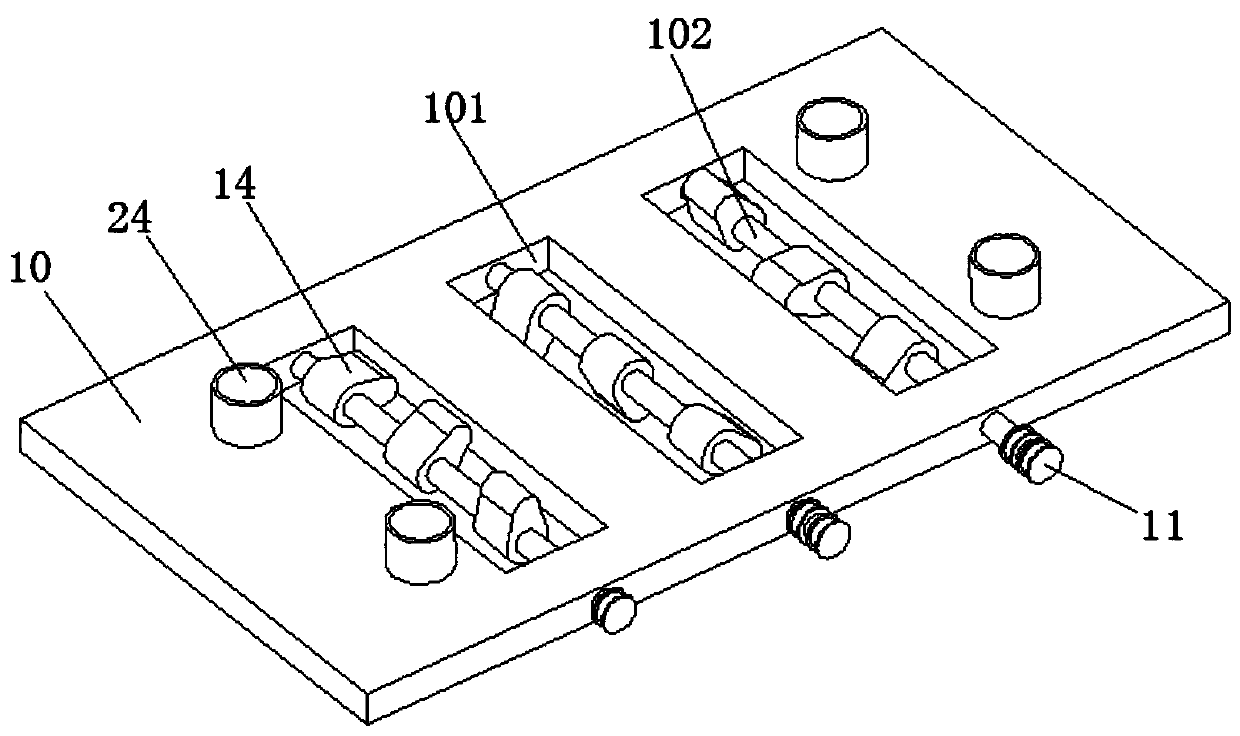

[0033]Embodiment 1 discloses an anti-seismic test device for a civil engineering structure, which includes a base plate 1 . In order to improve the shock and noise reduction effect of the entire device, a rubber shock absorbing pad 26 is provided on the lower surface of the base plate 1 . A first side plate 2 and a second side plate 3 are arranged on the side of the bottom plate 1 , and the first side plate 2 and the second side plate 3 are arranged perpendicular to each other. The inner surface of the first side plate 2 and the second side plate 3 is provided with an exciting motor 4, the output shaft of the exciting motor 4 is provided with a cam (not marked in the figure), and the exciting motor 4 is arranged on the fixed plate 5 Above, two sliding rods 6 are arranged on the fixed plate 5, two sliding holes are opened on the first side plate 2 and the second side plate 3, the sliding rod 6 passes through the sliding holes, and is located below the middle of the two sliding h...

Embodiment 2

[0037] Embodiment 2 is a further improvement on the basis of Embodiment 1, mainly adding the function of simulating shear waves in different directions, which will be introduced in detail below.

[0038] It includes a bottom plate 1, and in order to improve the shock absorption and noise reduction effect of the whole device, a rubber shock absorbing pad 26 is arranged on the lower surface of the bottom plate 1. A first side plate 2 and a second side plate 3 are arranged on the side of the bottom plate 1 , and the first side plate 2 and the second side plate 3 are arranged perpendicular to each other. The inner surface of the first side plate 2 and the second side plate 3 is provided with an exciting motor 4, the output shaft of the exciting motor 4 is provided with a cam (not marked in the figure), and the exciting motor 4 is arranged on the fixed plate 5 Above, two sliding rods 6 are arranged on the fixed plate 5, two sliding holes are opened on the first side plate 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com